Machining Transformation (MX)

GX

Green Transformation and Sustainability

Integrated processes increase your productivity,

reduce your energy consumption and maximize your profit

Increase sustainability

Learn more in our Webinars

DMG MORI GREENMODE

13 GREENMODE measures

- Brake Energy Recovery

- Advanced Auto Shutdown

- Advanced Electrical Energy Monitoring

- Adaptive Feed Control

- Pneumatics Monitoring

- Air-Purge-Free Scales

- Highly Efficient Chillers

- Water-Water Chillers

- Frequency-Controlled Pumps

- zeroFOG Mist Collector

- Adaptive Coolant Flow

- zero-sludgeCOOLANT

- AI Chip Removal

- Business Benefit Optimizer (BBO)

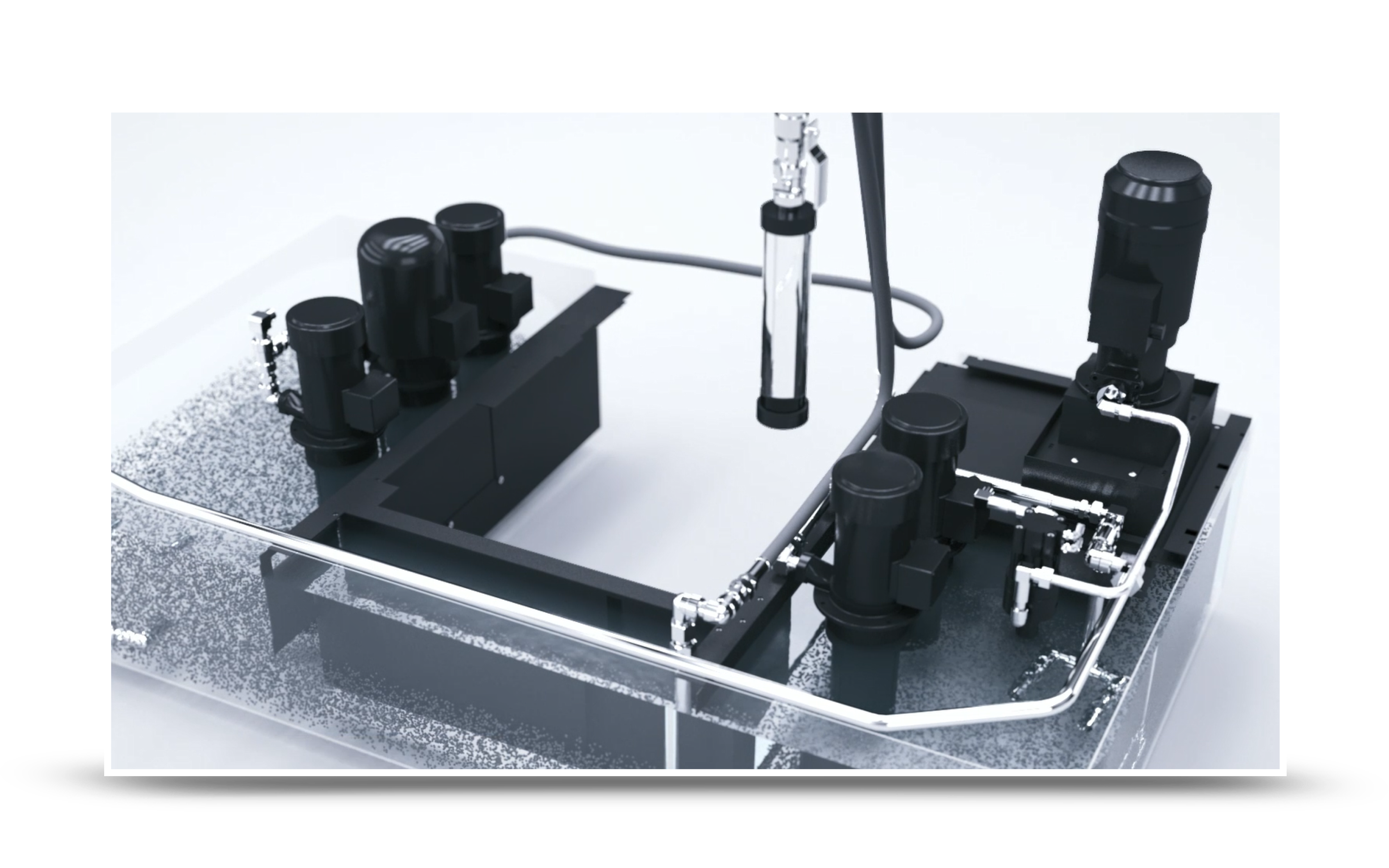

zero-sludgeCOOLANT

HIGHLY EFFICIENT COLLECTION OF SLUDGE IN THE TANK

- Reduce cleaning work of the colant tank singificantly, multiple coolant nozzles are arranged to stir coolant and efficiently collect fine casting sludge in tank up to 99 %

- Prevent clogging of pipes / nozzles and coolant pump breakage

- Extended coolant life

- 4 TONS REDUCED CO2 EMISSION / YEAR*1

zeroFOG

BUILT-IN MIST COLLECTION SYSTEM FOR A CLEAN WORK ENVIRONMENT

- High-speed fan driven by a specially developed high-efficiency motor for powerful suction of mist

- Mist collector with stable suction power

- Mist collection efficiency over 99.97 % for 0.3 μm particles

- 35 % less CO2 emissions and electricity consumption compared to conventional products

- 1.3 TONS REDUCED CO2 EMISSION / YEAR*2

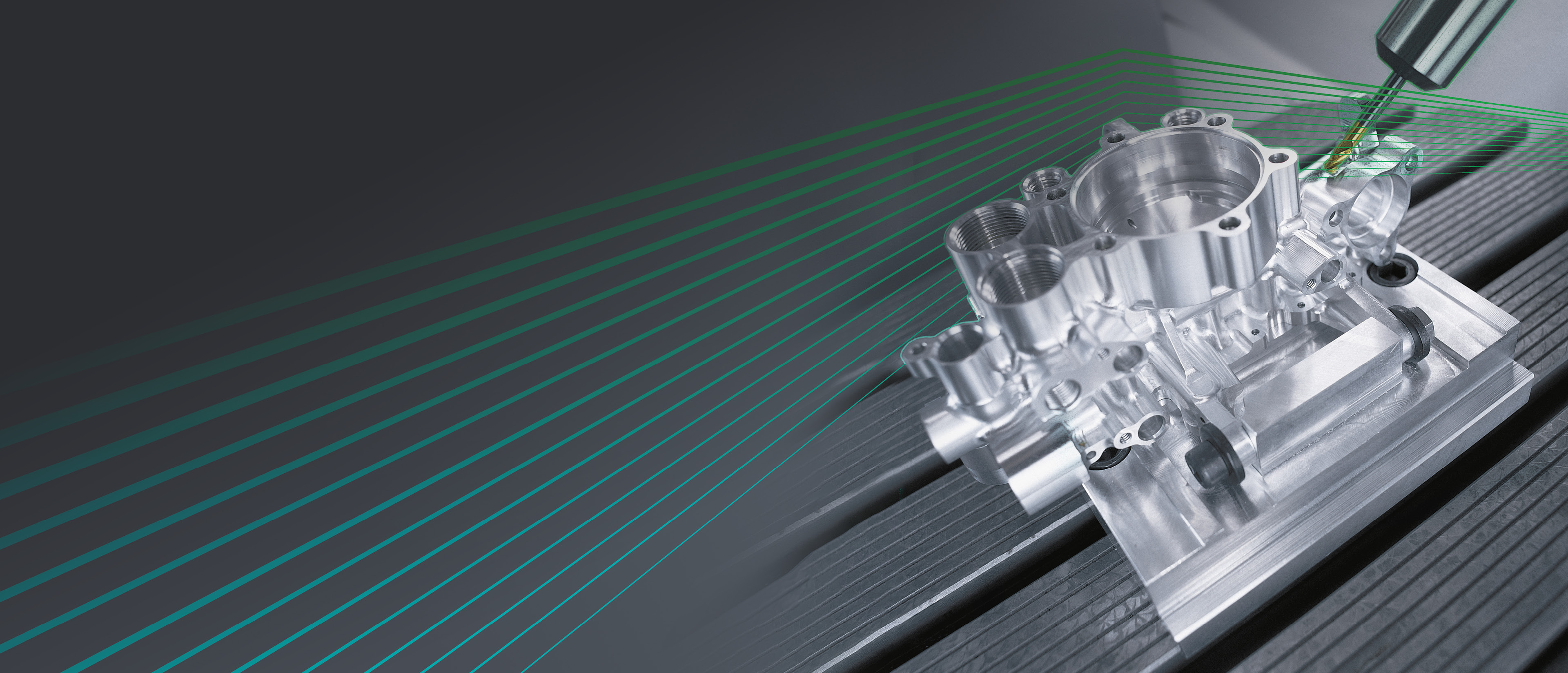

AI CHIP REMOVAL

EFFICIENT CLEANING OF CHIPS WITH AI

- High-accuracy analysis of chips accumulation with AI

- Motor-driven coolant nozzle to clean chips

- Reduced power consumption of coolant pump, coolant stops automatically in case of few chips

- 1.2 TONS REDUCED CO2 EMISSION / YEAR*3

1

Assuming that the entire tank volume (700 l) is exchanged once every four months. Also calculated with emission factor of 2.92 t-coxx2/t for waste oil incineration.

2

Compared with conventional products. Assuming operation of 16 hours per day and 240 days per year. Also calculated with a CO2 emission factor of 0.424 kg / kWh.

3

Assuming machine operation of 16 hours per day, 240 days per year and a cleaning rate of 30 %. Also calculated with a CO2 emission factor of 0.424 kg / kWh.

DMG MORI’s Initiatives / Evaluation by Third Parties

Compliance with TCFD recommendations

DMG MORI is committed to following the TCFD recommendations. Accordingly, we will disclose further extensive information in the areas of governance, strategy, risk management, and metrics and targets. This will offer investors and other stakeholders a more transparent view of DMG MORI’s climate-related risks and opportunities.

Read more

SBT certification

To enhance the effectiveness of our climate change mitigation efforts, we have established carbon footprint reduction targets for 2030. These targets received approval from the Science Based Targets Initiative (SBTi) in November 2021. Our objective is to achieve a 46.2% reduction in greenhouse gas emissions in Scopes 1 and 2, as well as a 13.5% reduction in Scope 3 emissions, by 2030, compared to the 2019 baseline.

Read more

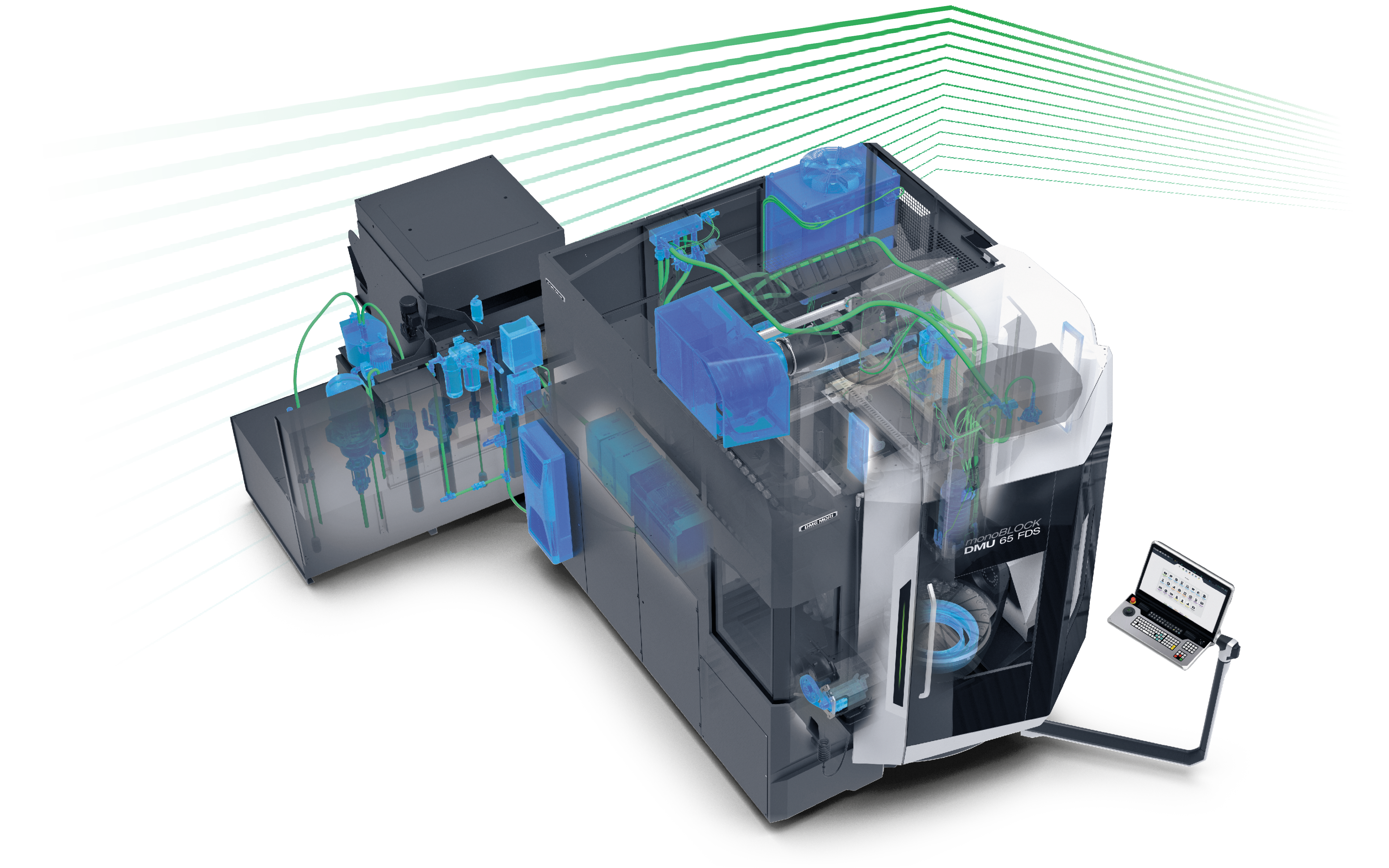

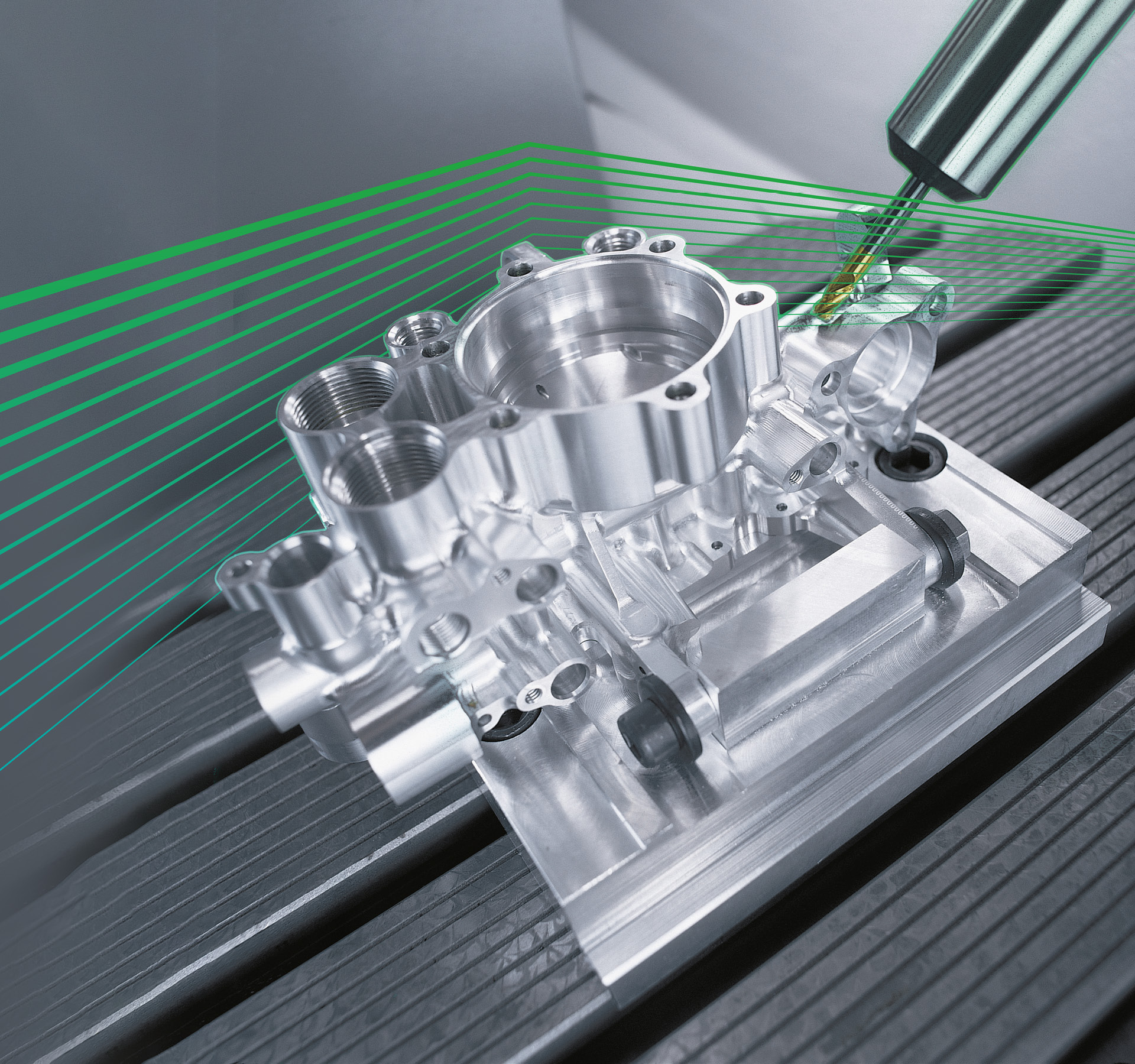

Process Integration

Higher utilization of a complete machining center, instead of partial utilization of several simple machines.

Automation

For additional low-man or manless night and / or weekend shifts.

Digital Transformation (DX)

From CAD-CAM solutions and post-processors to simulation using Digital Twin and DMG MORI technology cycles for up to 60 % shorter programming time

Green Transformation (GX)

Integrated processes increase your productivity, reduce your energy consumption and maximize your profit.

Or call us!

Or call us!