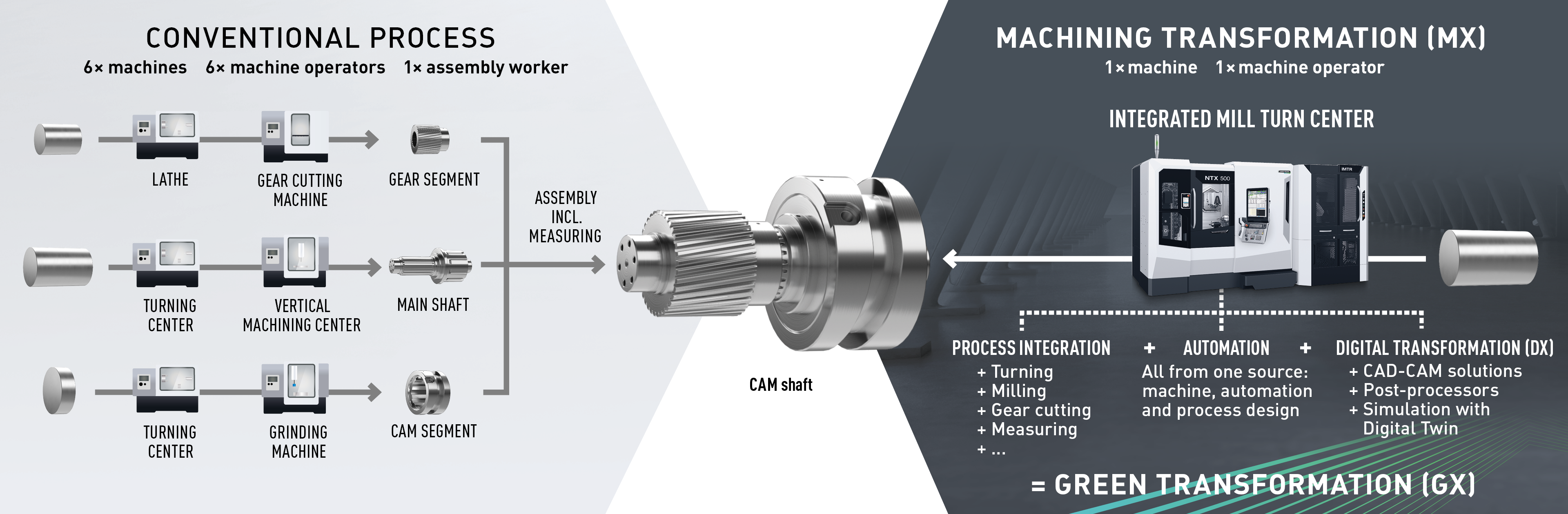

Machining Transformation (MX)

Process Integration

Higher utilization of a complete machining center,

instead of partial utilization of several simple machines

1 instead of 6 machines

Key points of process integration

using Multi-axis Machines

- All processes on a single machine

- Integrated specialized machining

- Integrated measurement

- Facilitates automation

- Sustainable production

Learn more in our Webinars

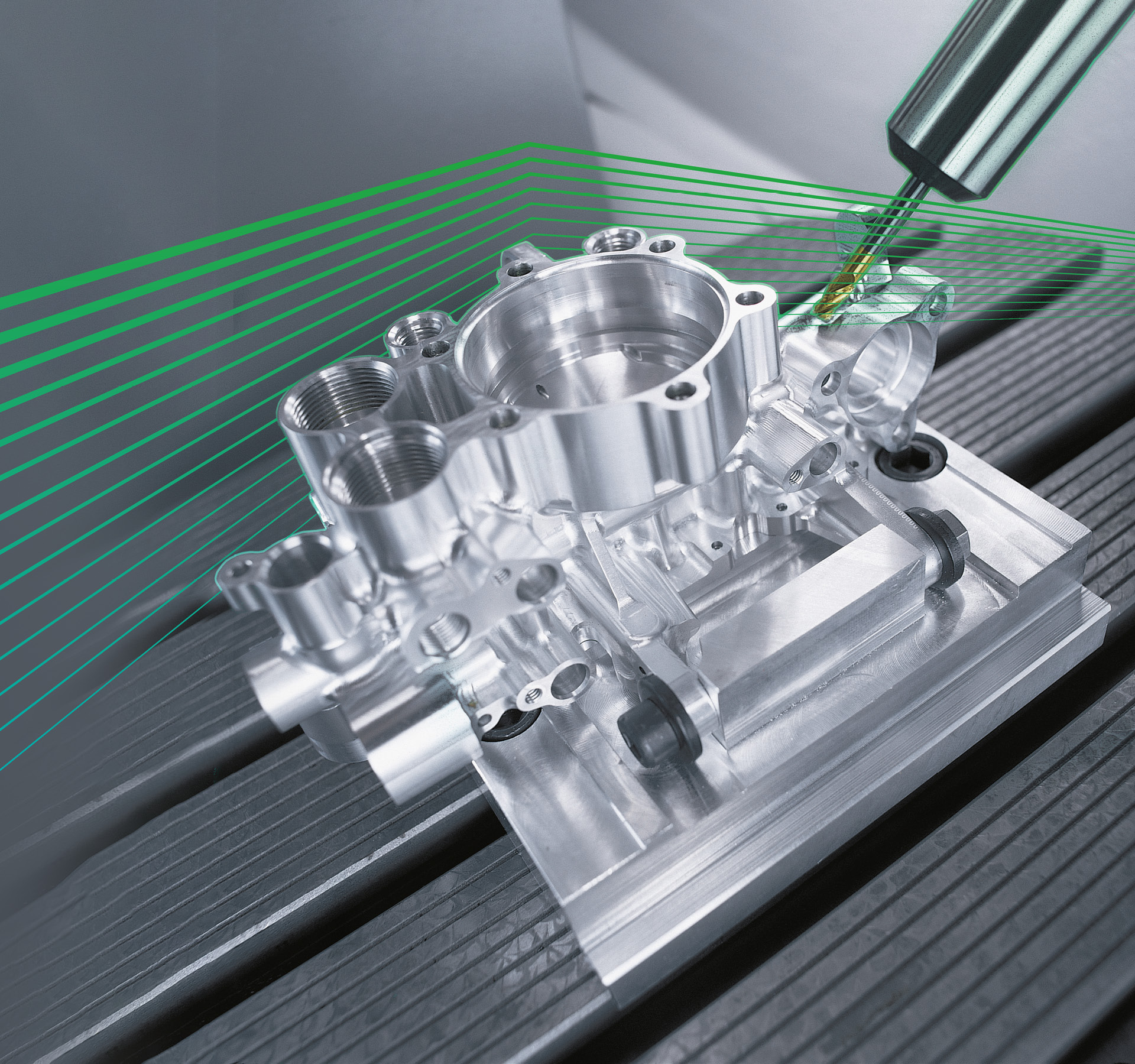

5-Axis Machining

The basis for Machining Transformation (MX)

5-axis opens opportunities in process integration. Workpieces that were sequentially processed by multiple machines can now be manufactured in one technology-integrated machine in a single

High utilization of one machining center instead of partial utilization of several simple machines. Several processes such as turning, milling, grinding, measurement functions and many more are combined in one machine tool for higher productivity.

Integrated processes

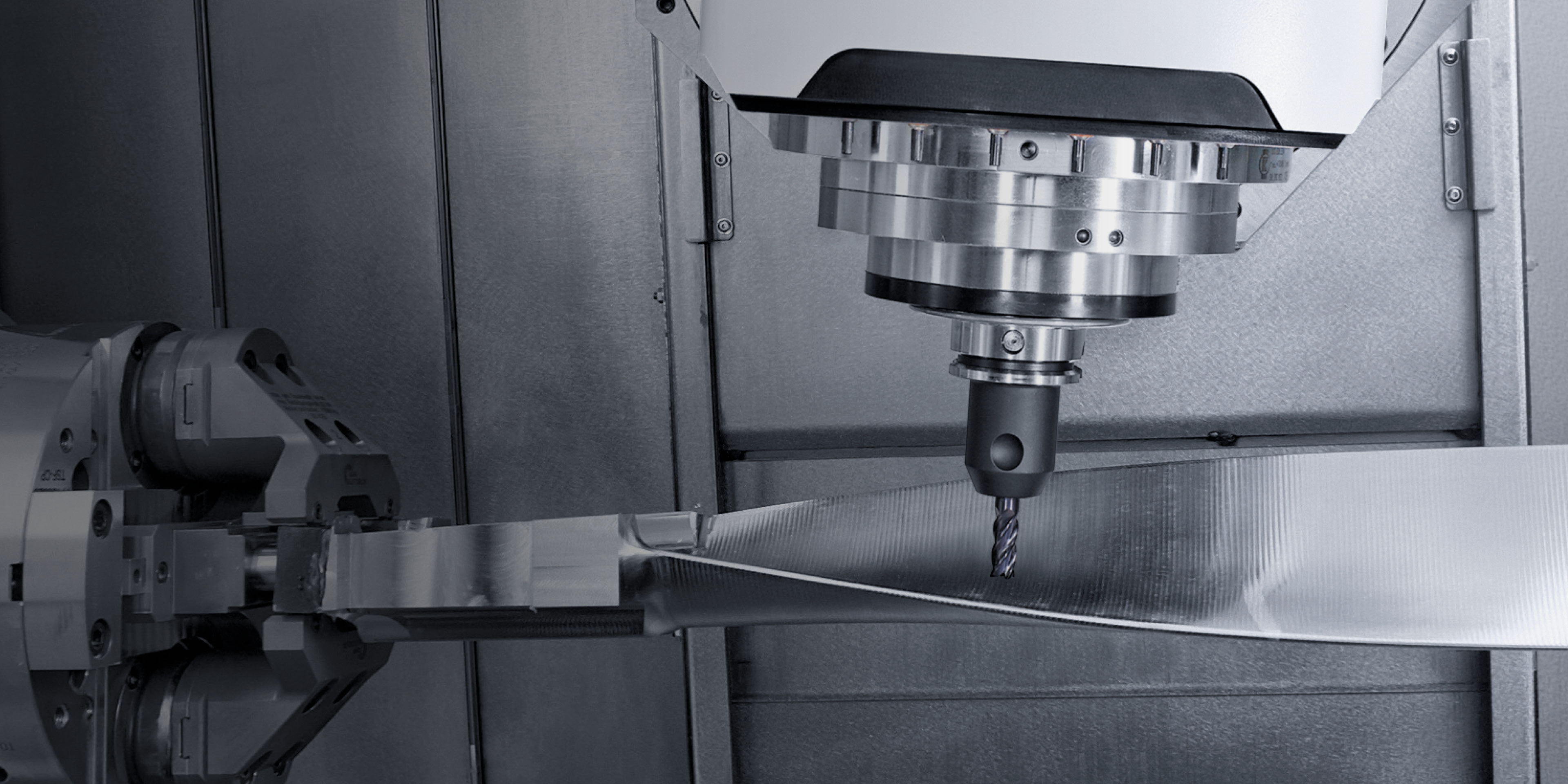

Mill & Turn (FD)

Turning on 5-axis milling machines

Turn & Mill

6-sided complete machining by turning and milling

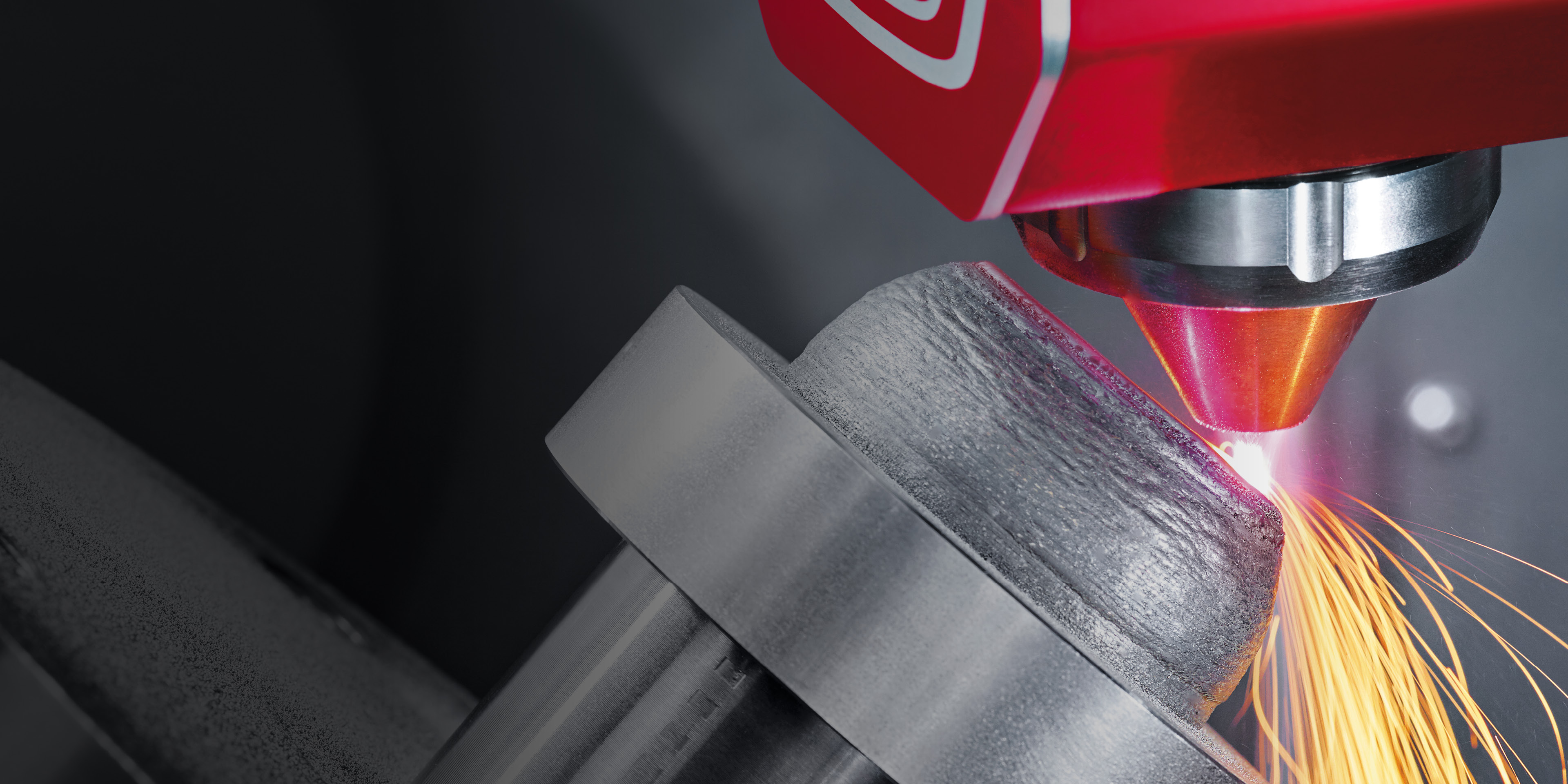

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

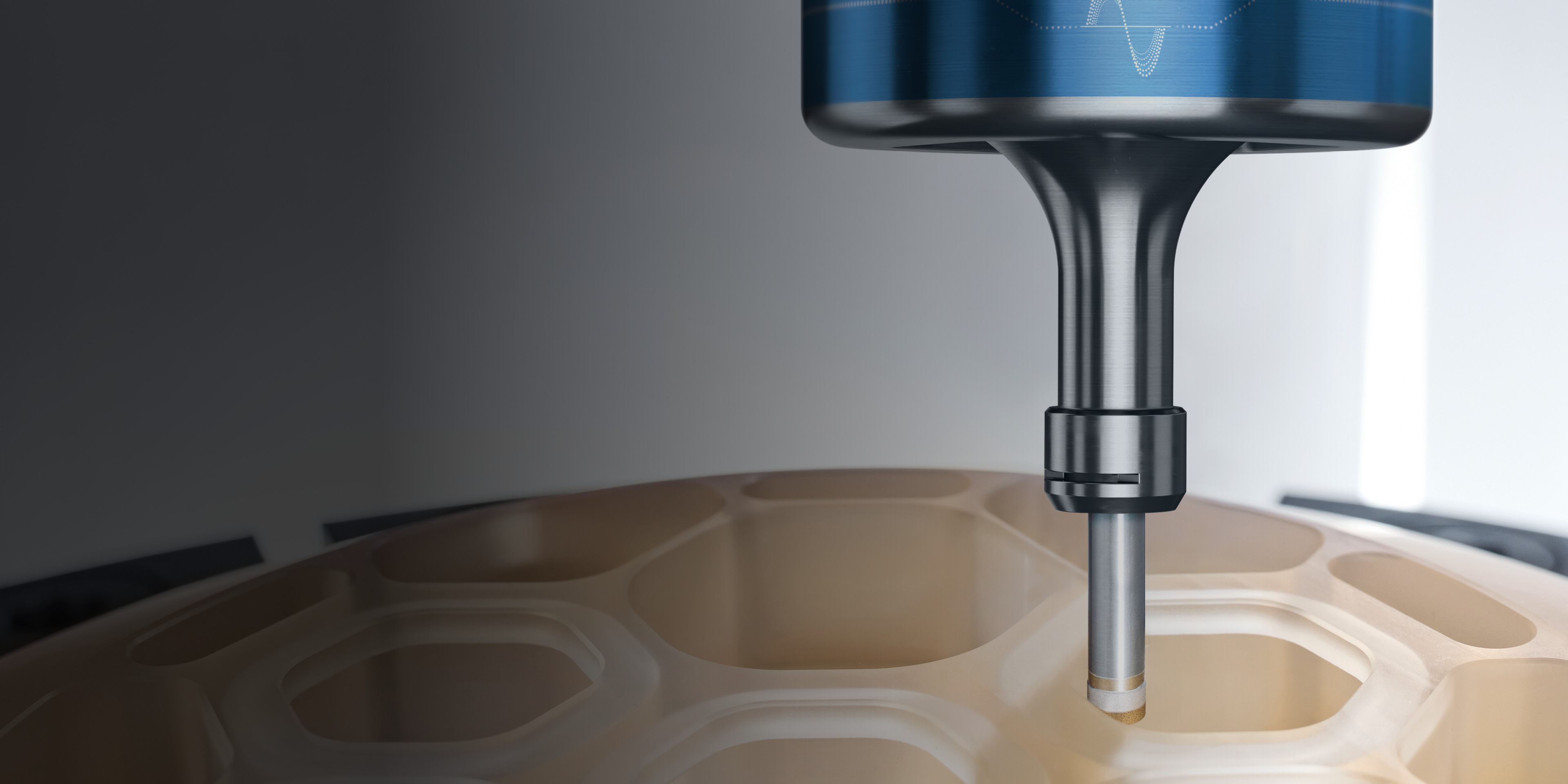

ULTRASONIC

Reduced process forces for very high productivity

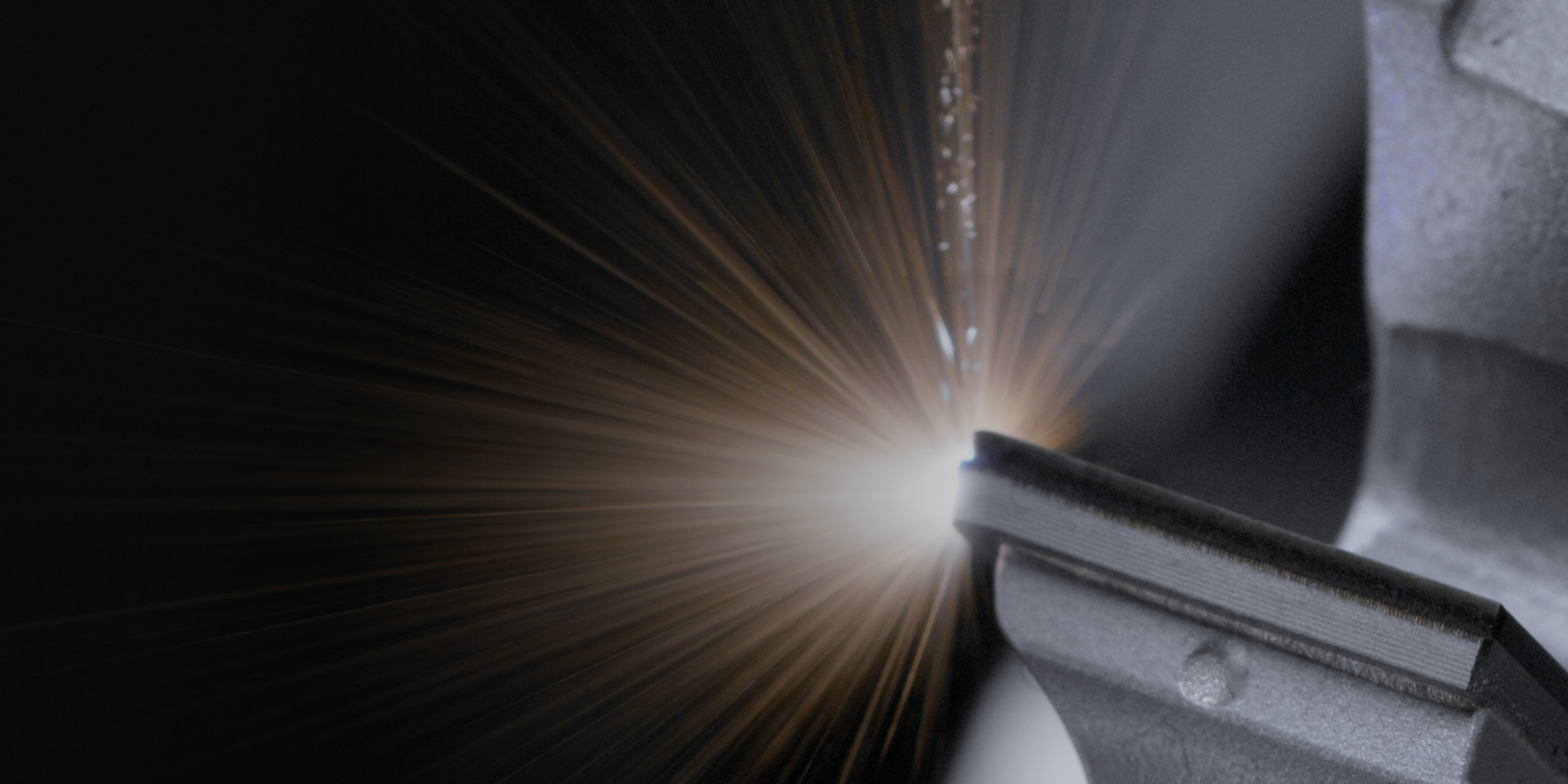

LASERTEC

Contact-free 5-axis laser machining

Additive Manufacturing

Milling, Turning and Additive Manufacturing on

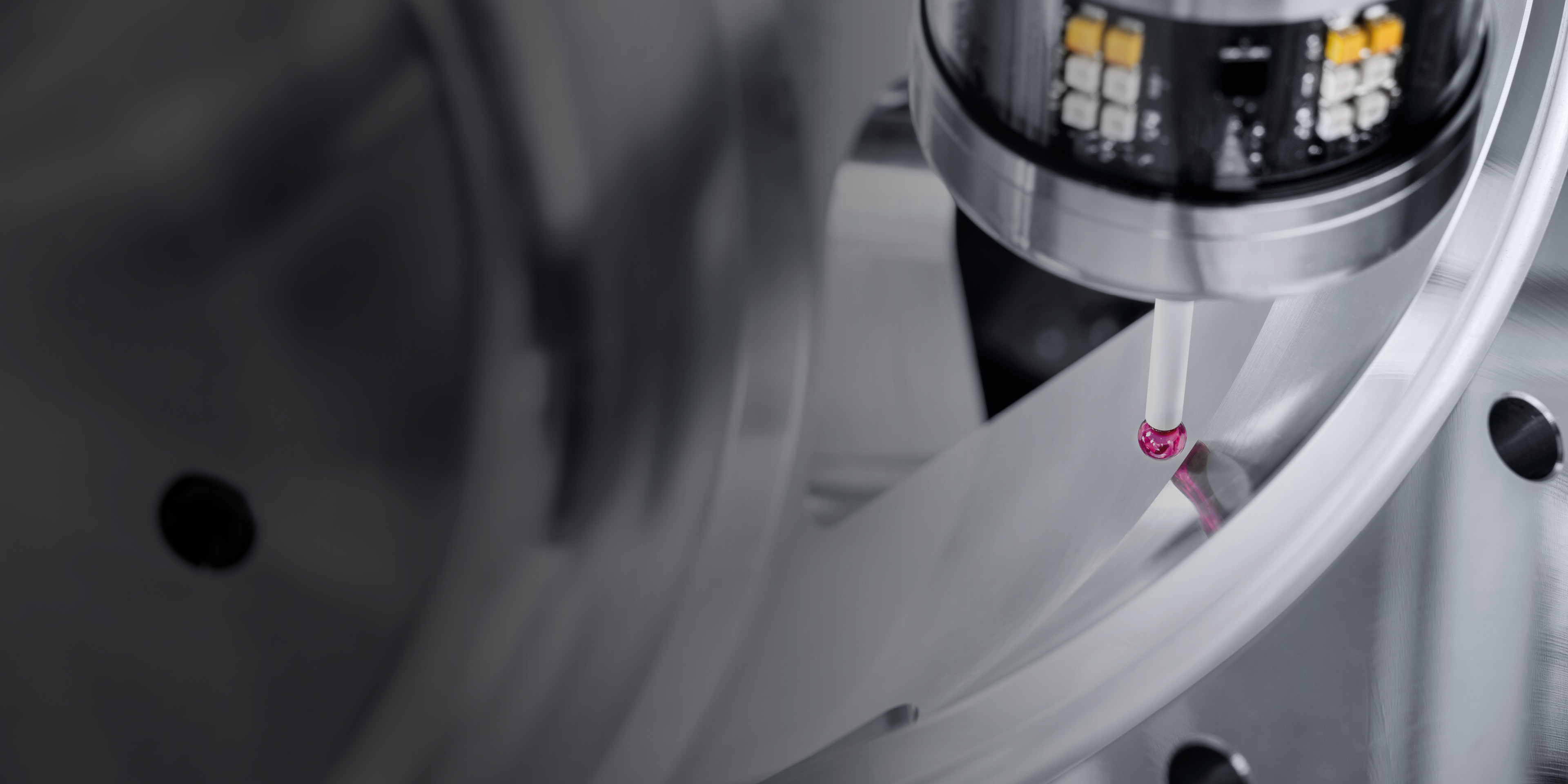

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Process Integration

Higher utilization of a complete machining center, instead of partial utilization of several simple machines.

Automation

For additional low-man or manless night and / or weekend shifts.

Digital Transformation (DX)

From CAD-CAM solutions and post-processors to simulation using Digital Twin and DMG MORI technology cycles for up to 60 % shorter programming time

Green Transformation (GX)

Integrated processes increase your productivity, reduce your energy consumption and maximize your profit.

Or call us!

Or call us!