Integrated processes

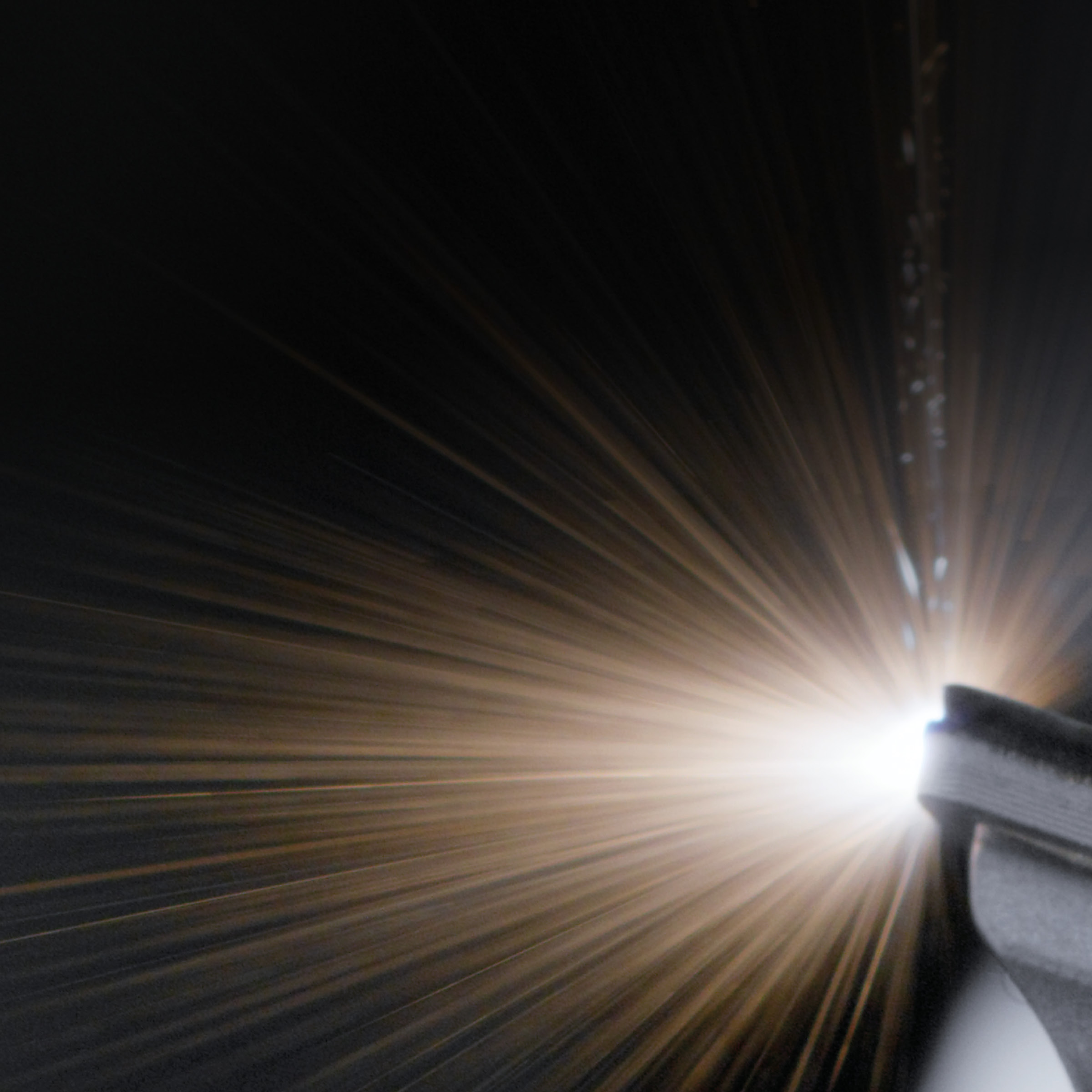

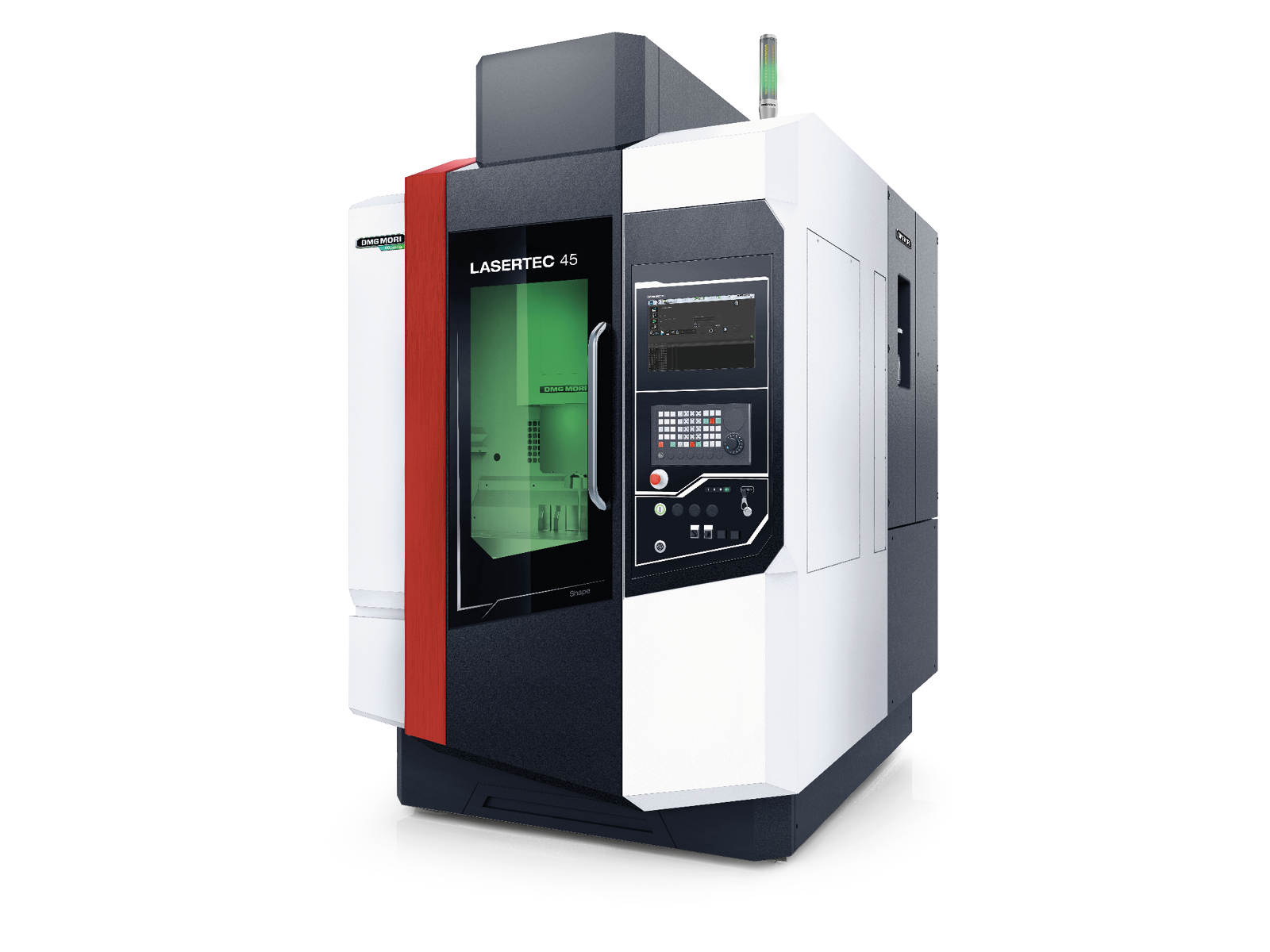

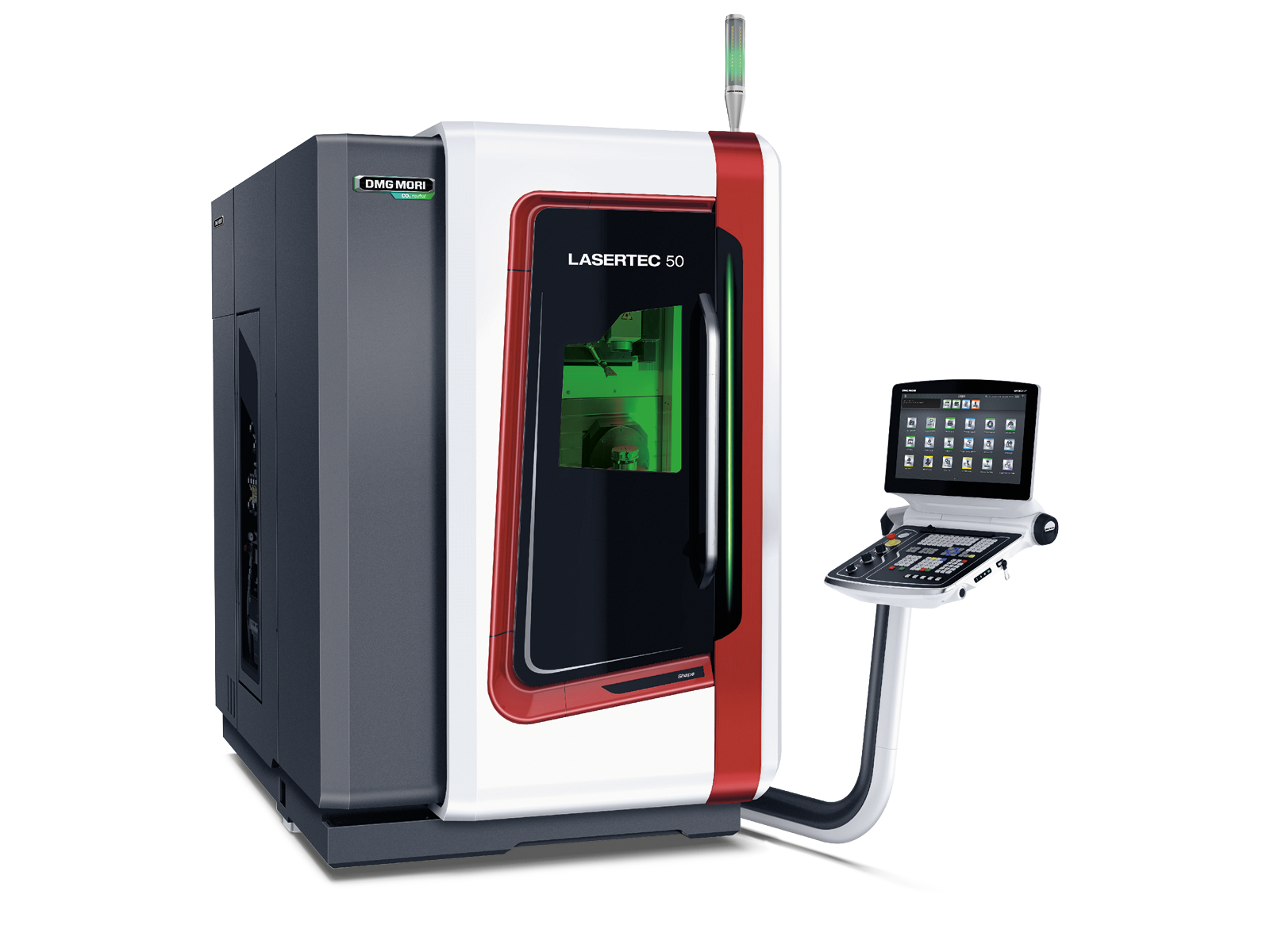

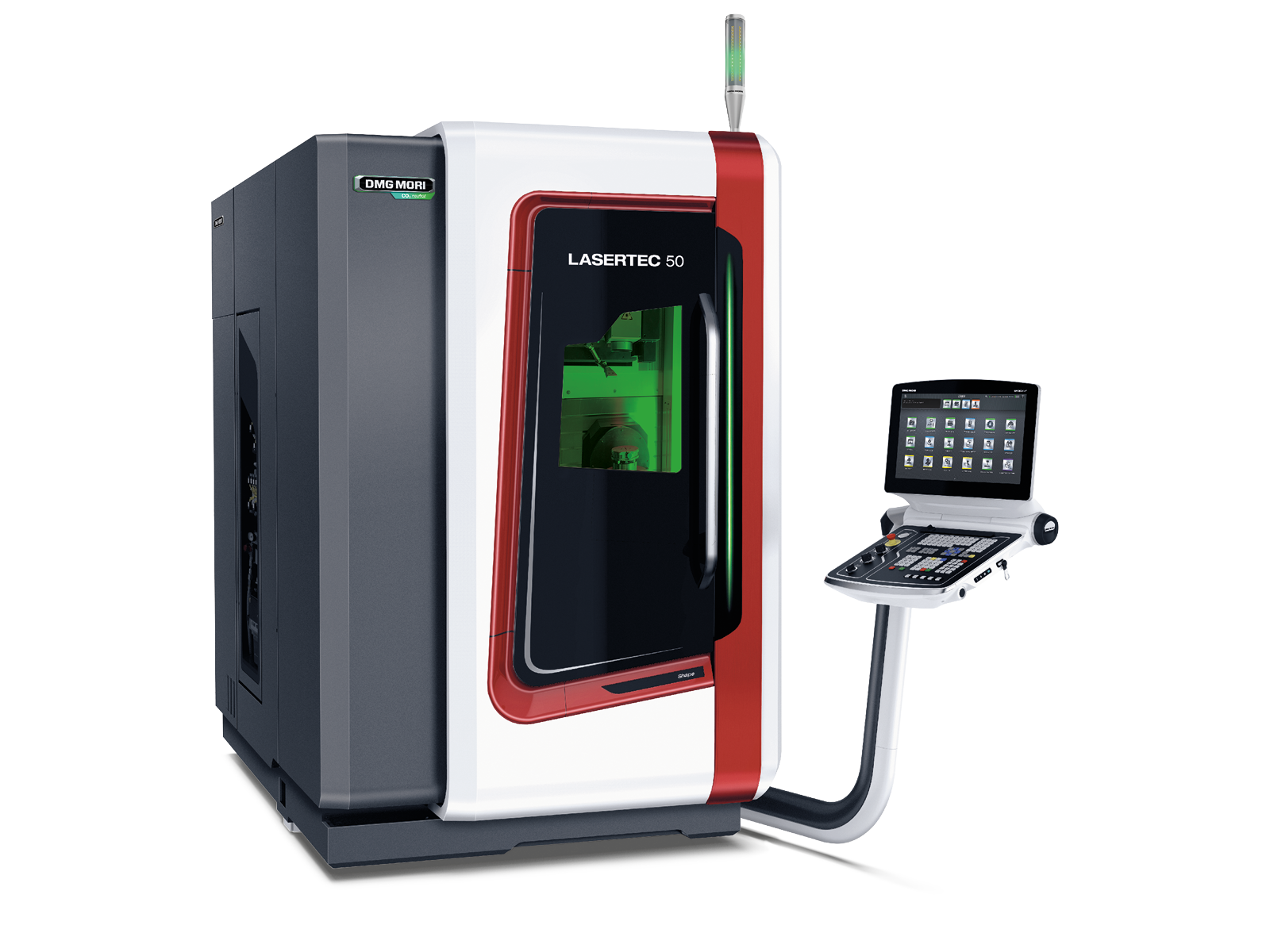

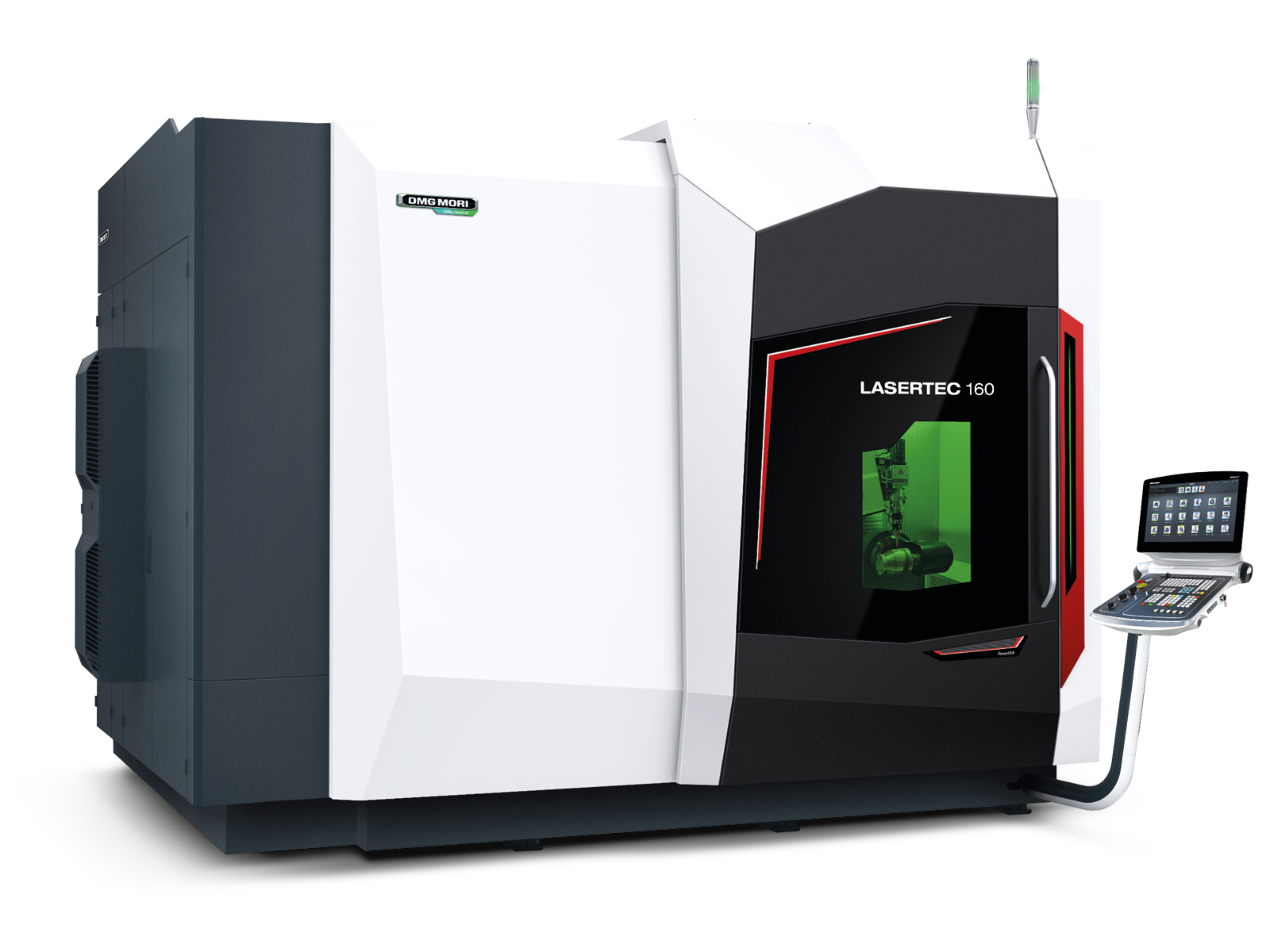

LASERTEC

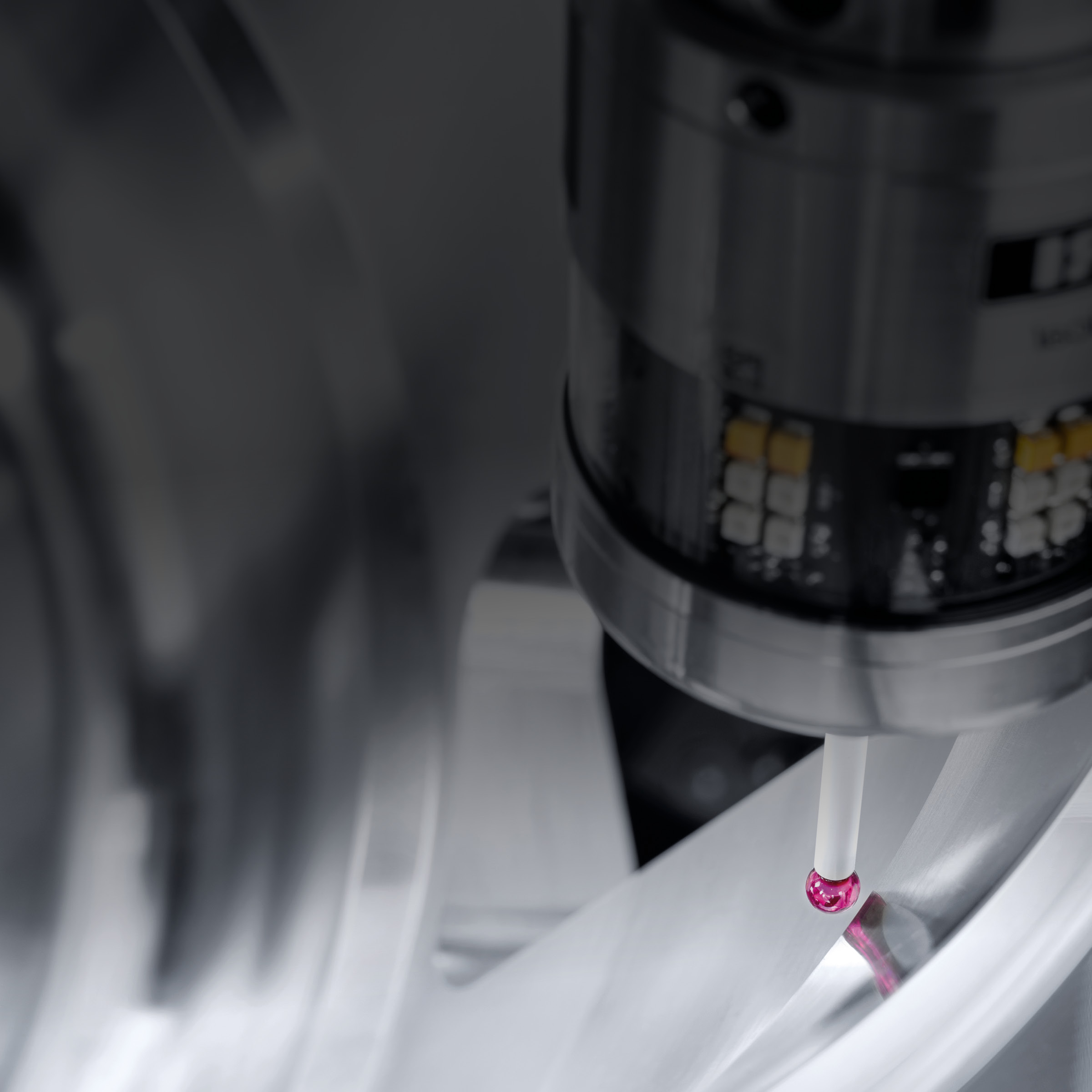

Contact-free 5-axis laser machining

3 Laser-Technology Sectors

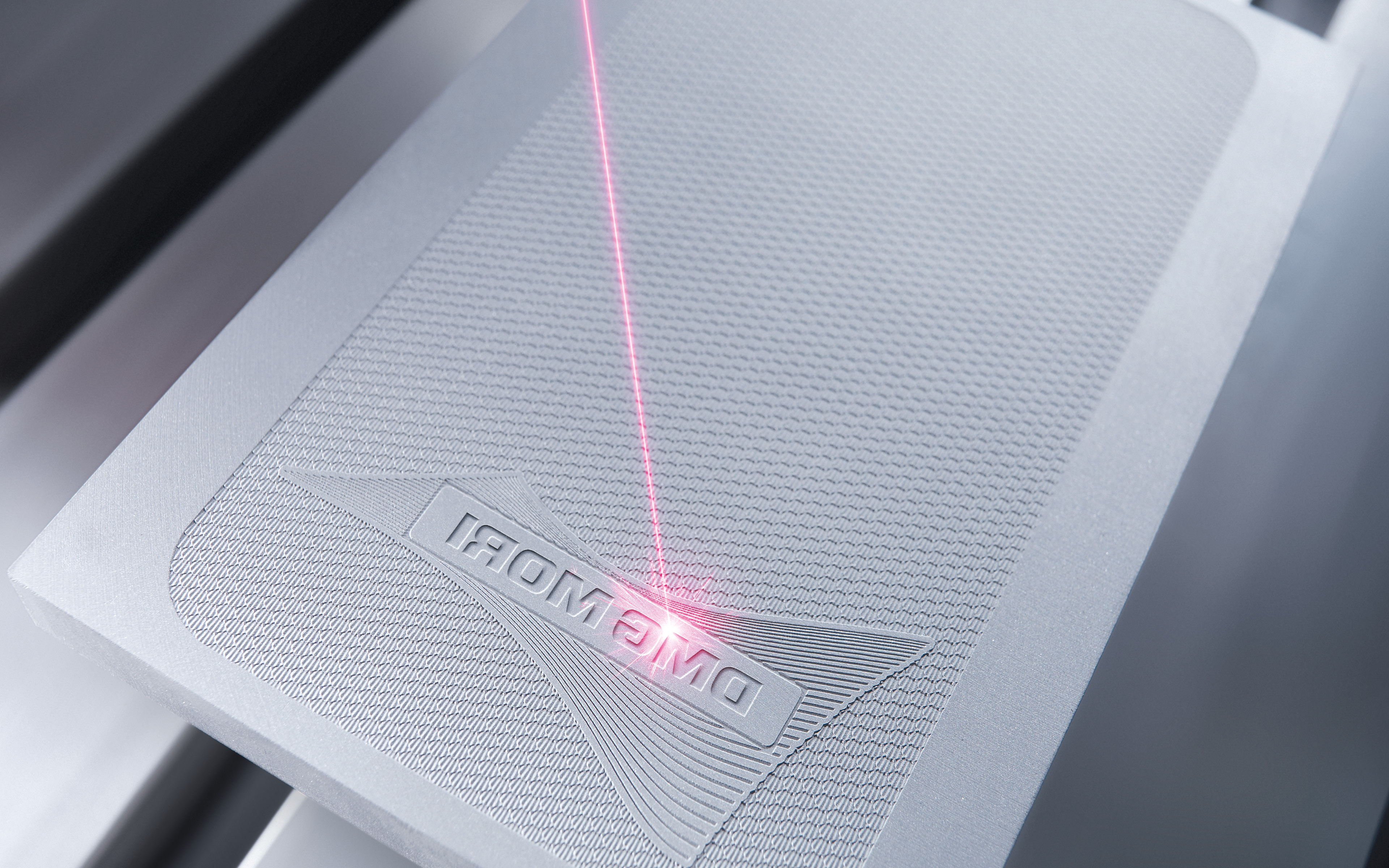

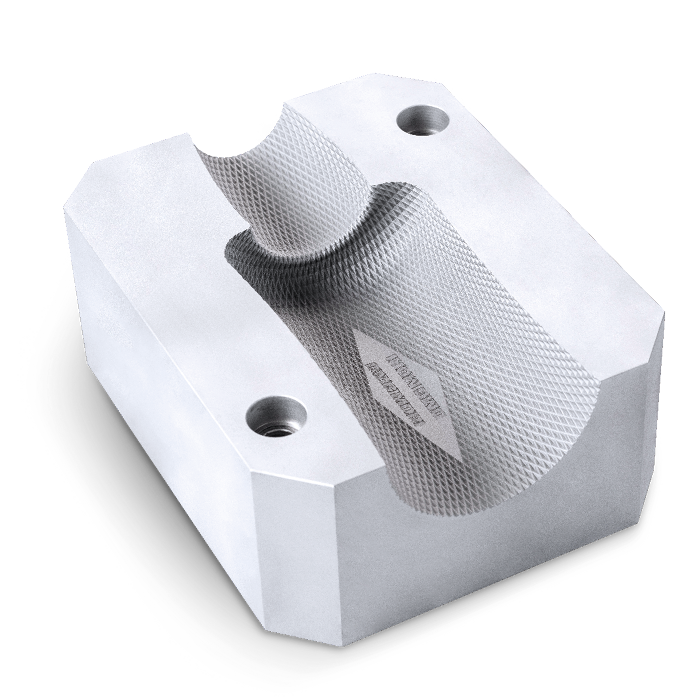

LASERTEC Shape

Laser texturing of geometrically defined surfaces in injection molds for Die & Mold and 3D laser ablation

for the production of technical miniature molds, press dies and embossing tools.

5-axis laser texturing with fiber laser

- Complex and sophisticated textures in 3D free-form surfaces, engravings and inscriptions.

- Lasering of surface textures with technical properties:

- Scratch-resistant surfaces

- Supermatte surfaces

- Hydrophobic surfaces

- High speed Z-shifter for fast positioning of the machining point in the Z-direction.

- Highest repeatability and reproducibility

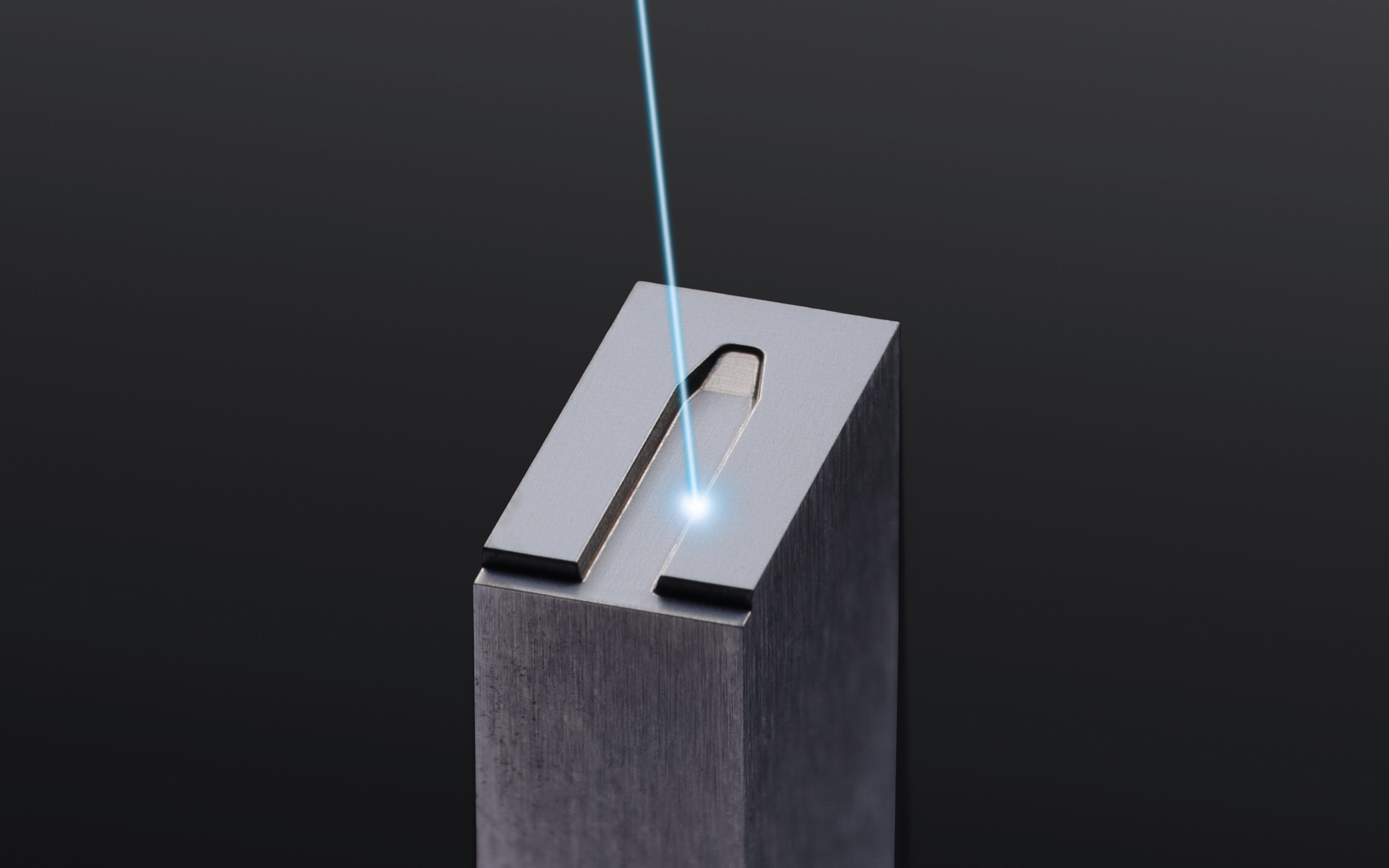

5-axis laser ablation with femtosecond laser

- Ultra-short pulse laser enables machining of tungsten carbide, glass, ceramics with surface finishes down to Ra 0.1 µm

- Contact-free and gentle machining without heat input into the material avoids cracks and material stresses

- Tool life can be increased by a factor of up to 10 for carbide embossing dies

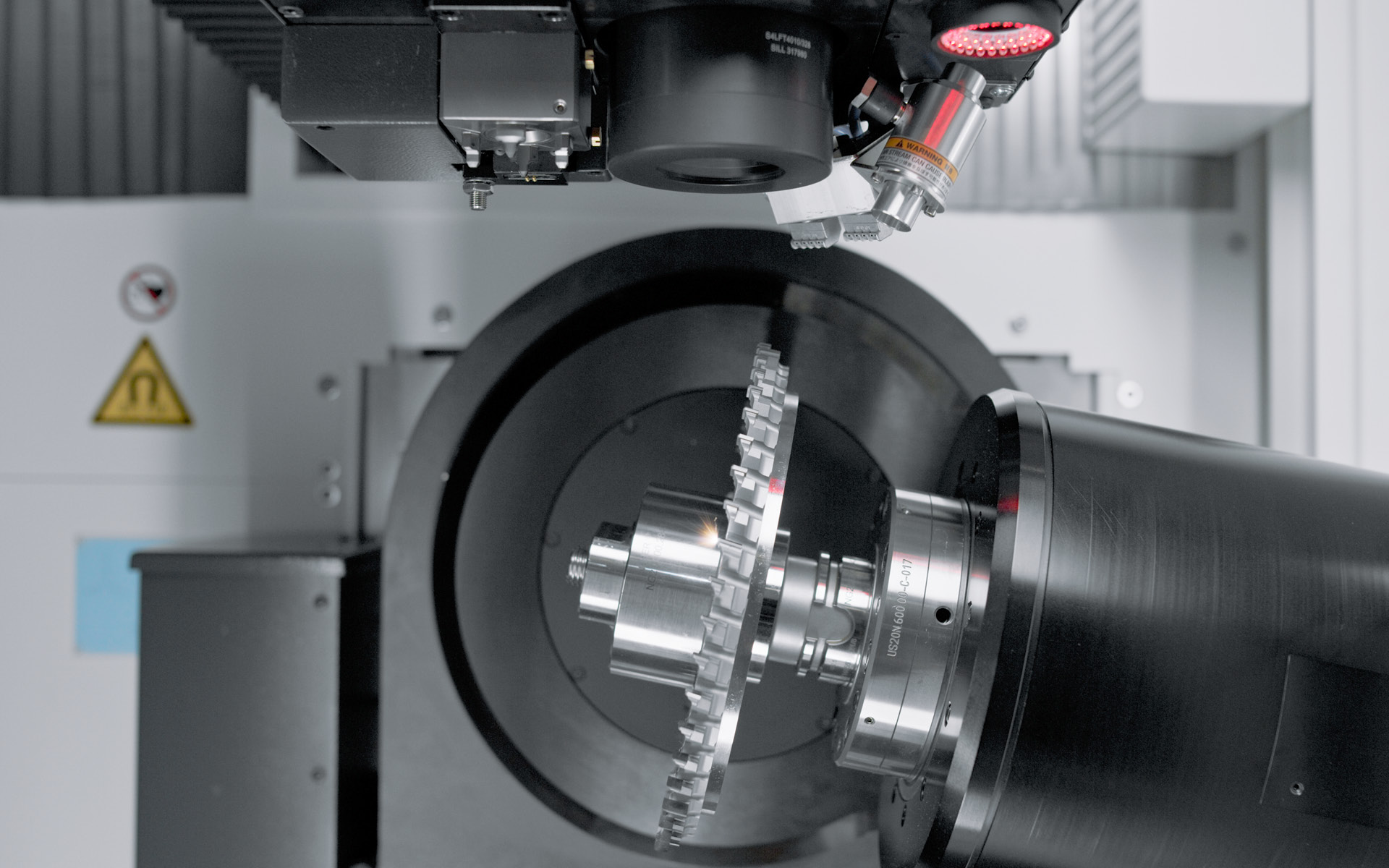

LASERTEC PrecisionTool

Complete machining of cutting edges incl. clearance angle, chip breakers and defined cutting edge roundings in ultra-hard materials with up to 3 mm/min.

- Up to 210 % faster and up to 56 % lower costs per part than EDM machining

- Laser finishing of PCD, PCBN, CVD, MCD with up to 3.0 mm/min.

- Smallest cutting edge radii ≤ 1µm for best surface finish on the end product

- Freely selectable defined cutting edge rounding of 3, 6, 9, 12, 15 µm

- Perfect, chipping-free cutting edges, clearance angles and chip breakers

LASERTEC PowerDrill

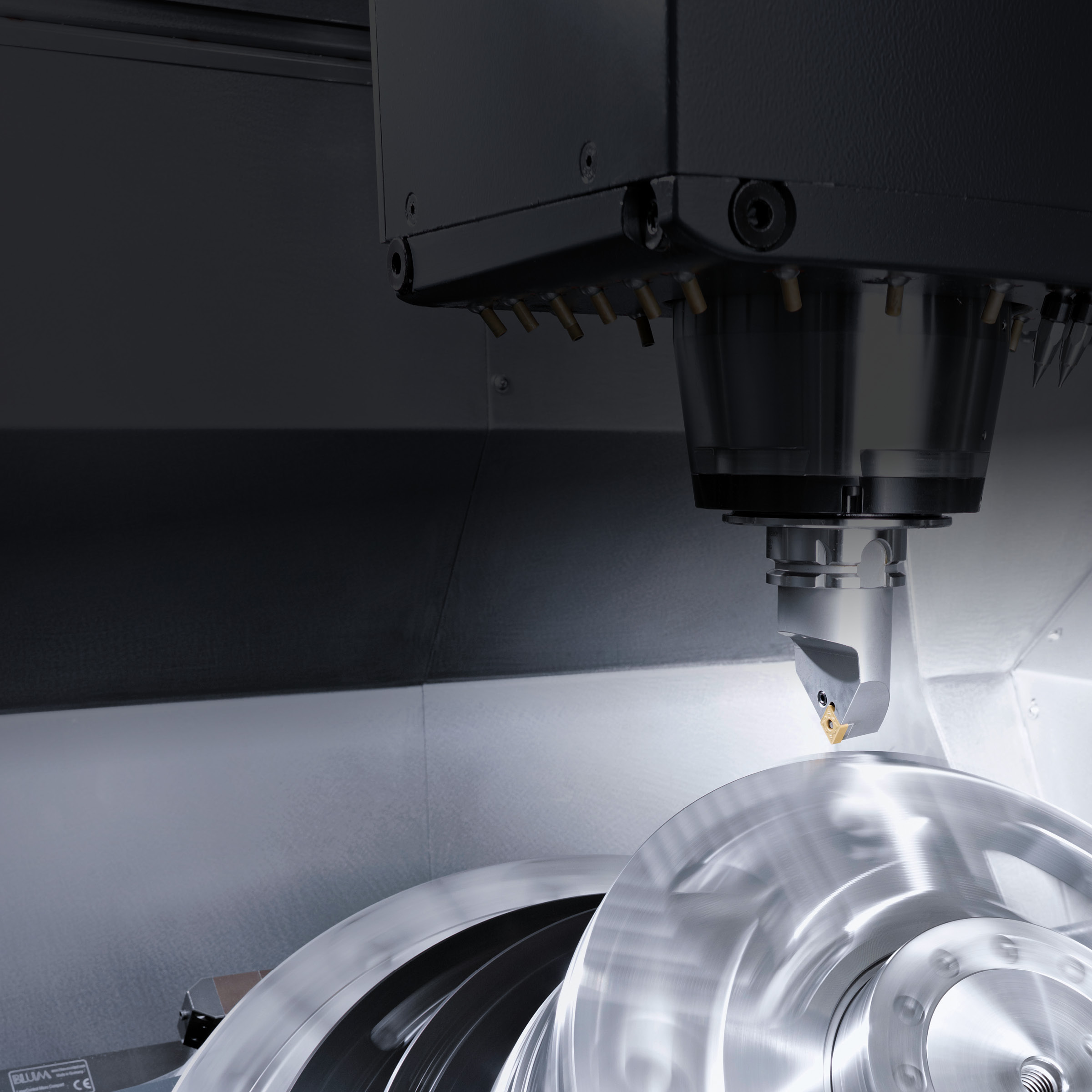

5-axis laser precision drilling of cooling air holes in turbine components for aircraft engines and industrial gas turbines.

- 5-axis laser precision drilling of turbine blades and other components for aerospace / stationary gas turbines

- Drilling on the Fly with up to 500 holes / second

- Shaped hole technology for machining conical exit funnels

Workpieces

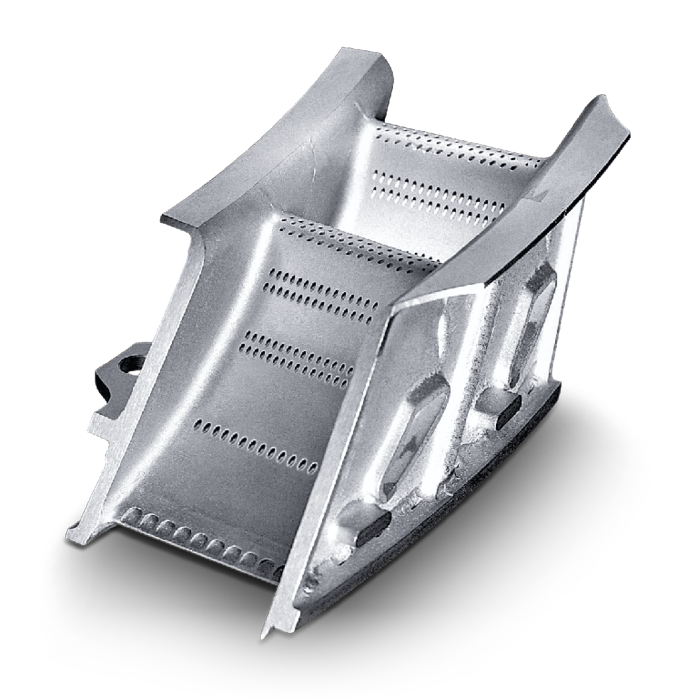

Blow mold for PET-bottles

- Steel

- Die & Mold

- 150 × 120 × 58.5 mm

Pressing die

- Tungsten Carbide

- Die & Mold

- 3 × 5 × 0.2 mm

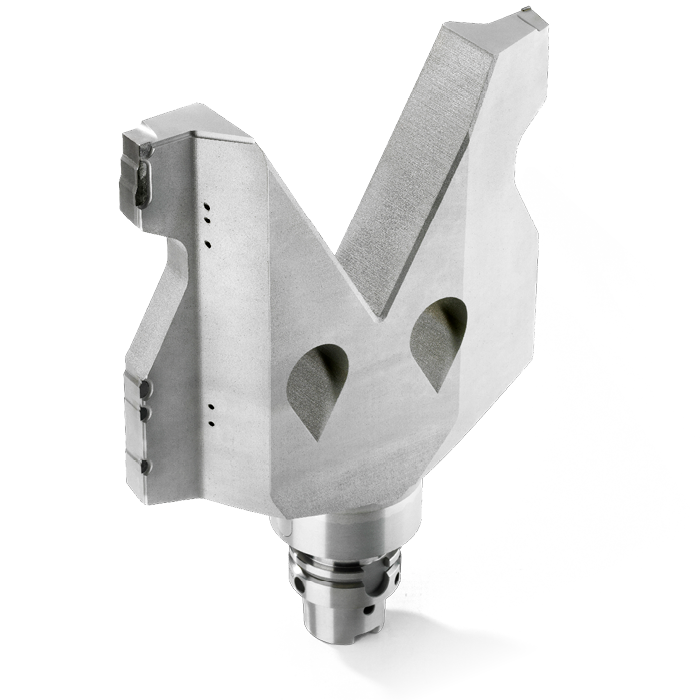

Boring tool

- PCD

- Precision Tools

- ø 250 × 313 mm

Turbine vane

- Inconel

- Aerospace

- 190 × 100 × 80 mm

Mill & Turn (FD)

Turning on 5-axis milling machines

Turn & Mill

6-sided complete machining by turning and milling

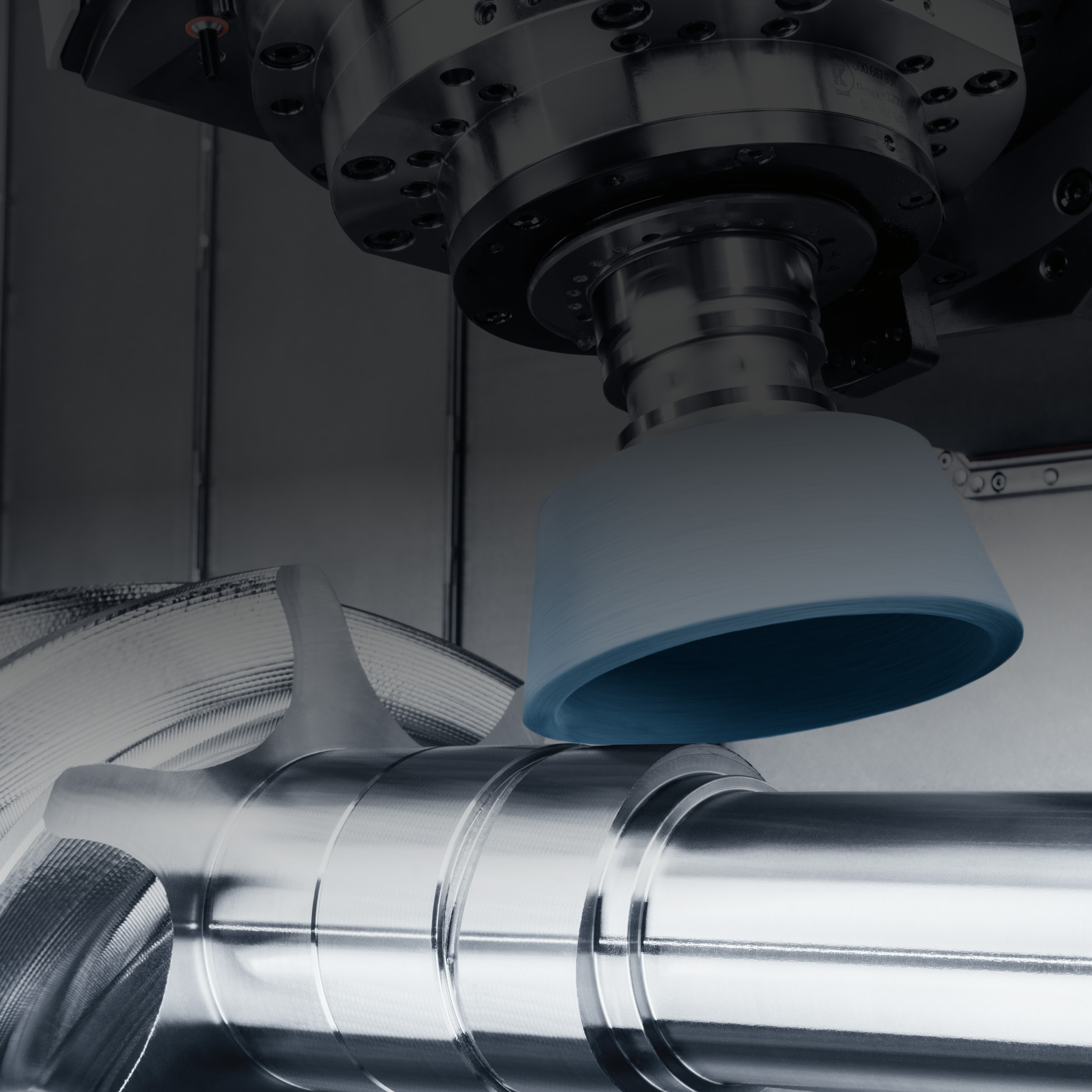

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

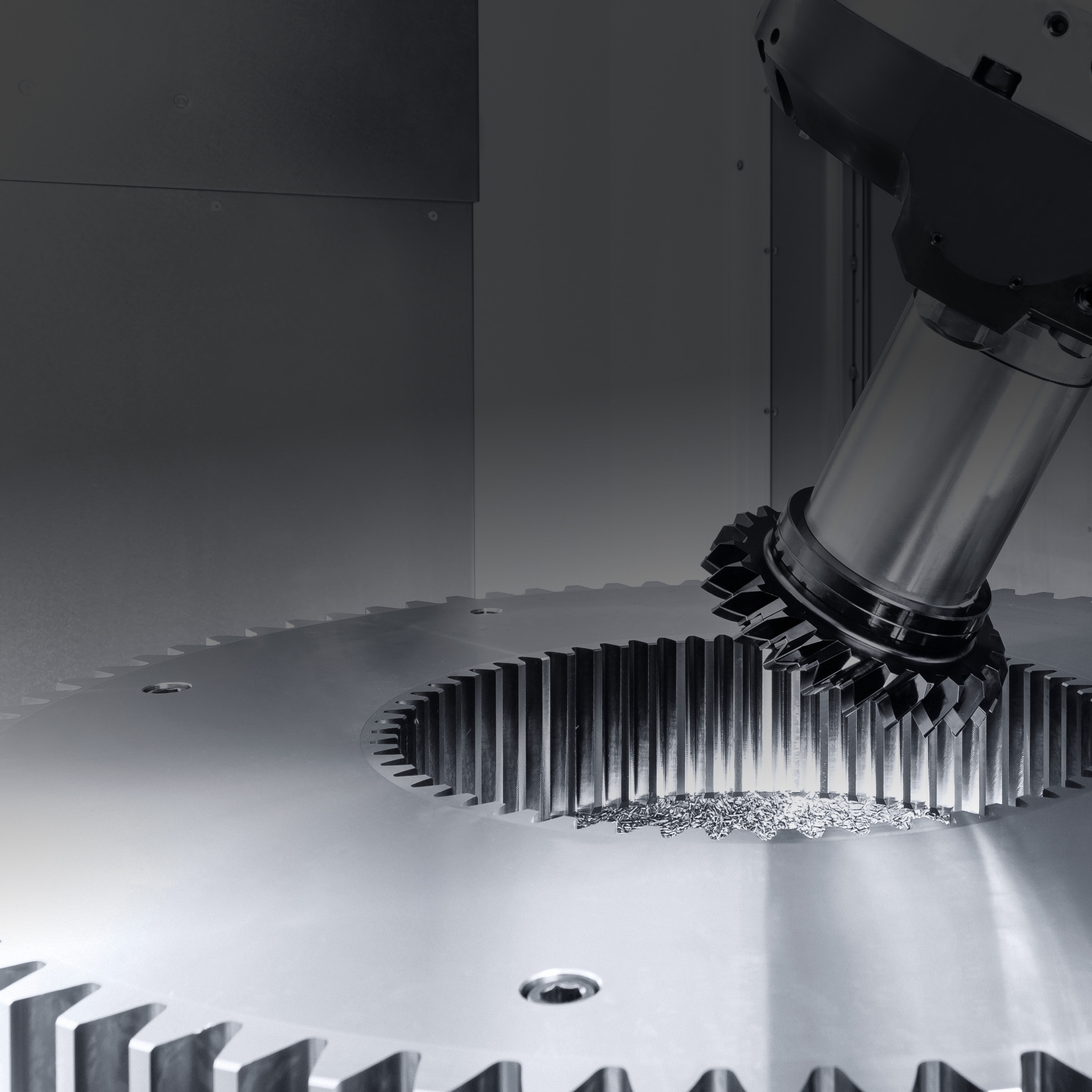

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

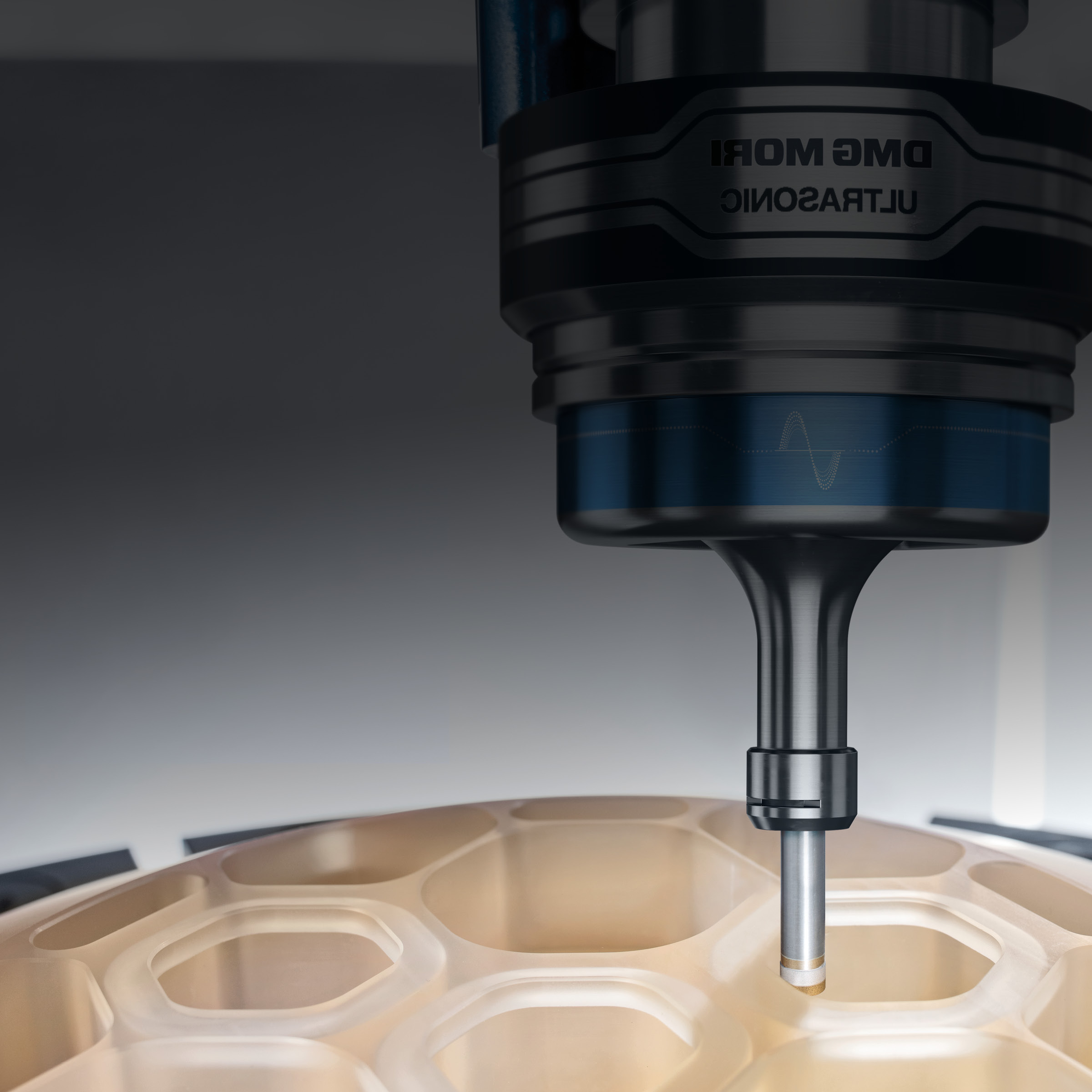

ULTRASONIC

Reduced process forces for very high productivity

LASERTEC

Contact-free 5-axis laser machining

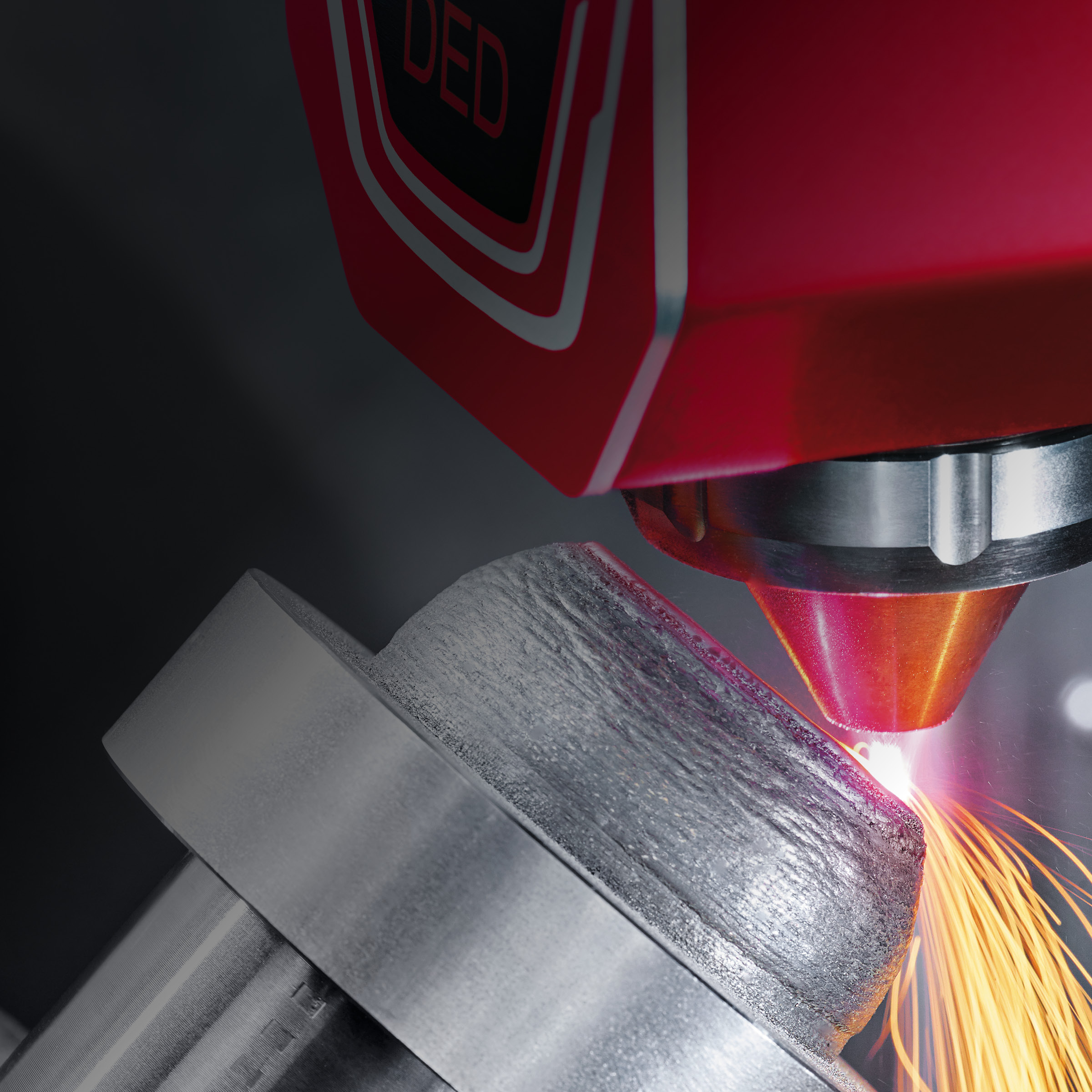

Additive Manufacturing DED hybrid

Milling, Turning and Additive Manufacturing on

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Or call us!

Or call us!