Integrated processes

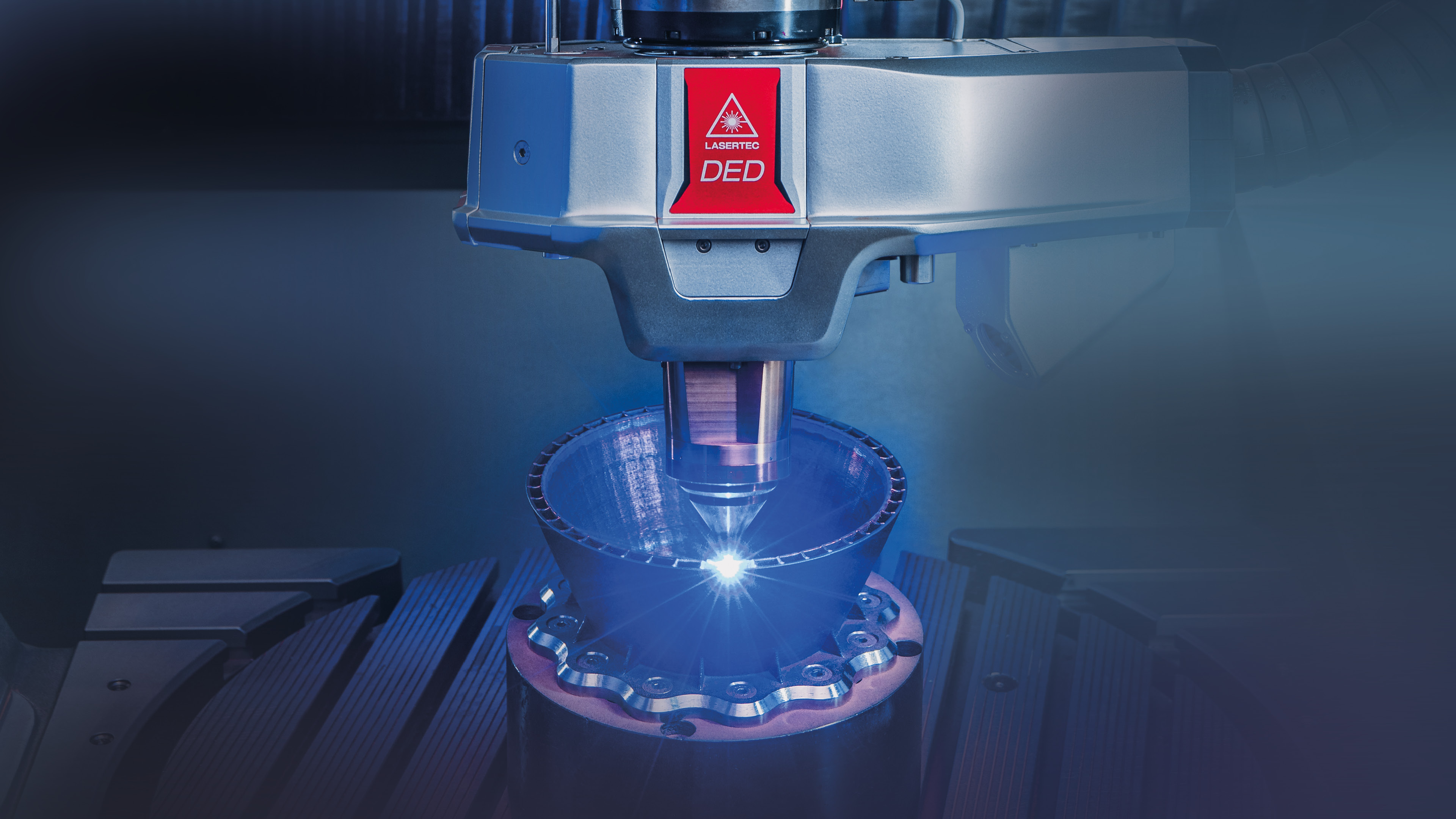

Additive Manufacturing

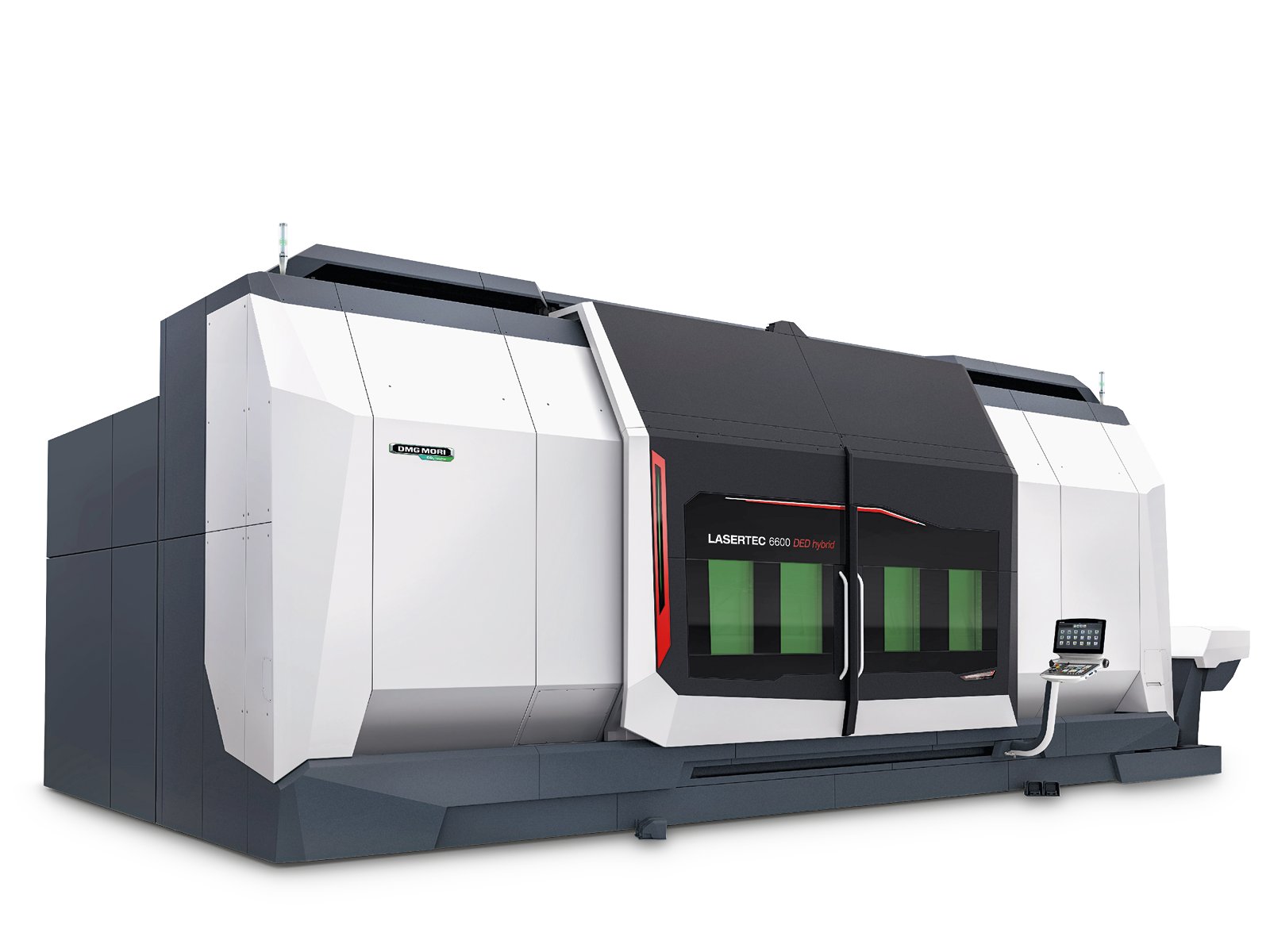

Milling, Turning and Additive Manufacturing on

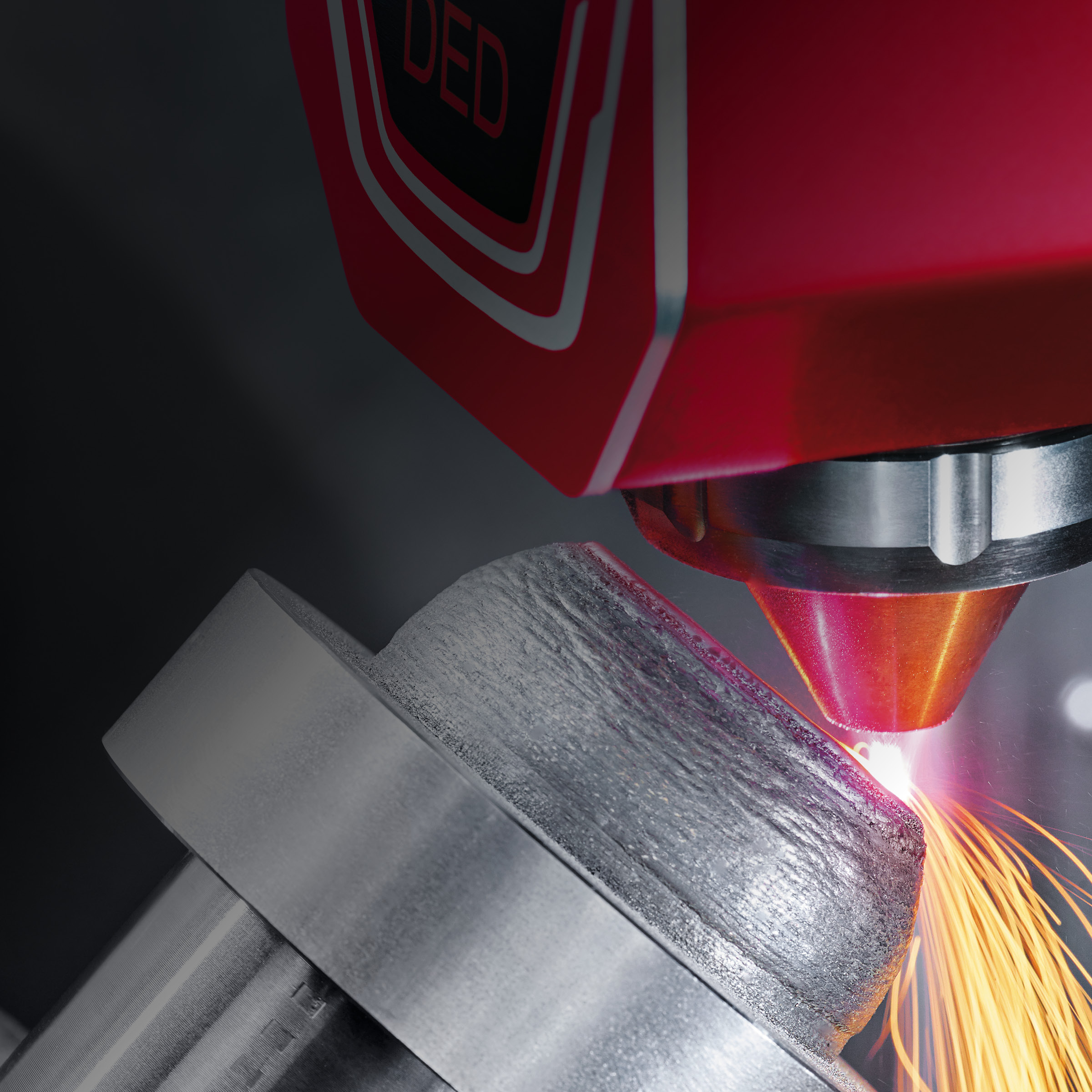

Highlights

- The laser deposition head is handled by a fully automatic shuttle without manual intervention

- Up to 1 kg build-up rate per hour (depending on material): 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

Fibre-guided diode laser

Fibre-guided diode laser with 3,000 W power and 600 µm fibre diameter as standard

Blue wavelength Laser

Optional with fibre guided laser with 2 kW and blue wavelength (450 nm), perfect for highly reflecting materials like copper

Workpieces

2-channel heat exchanger

- CuAl10 / 316L

- Energy

- ø 200 × 250 mm

Die cast core

- Ferro 55 + CuAl10

- Die & Mold

- 120 × 82 × 123 mm

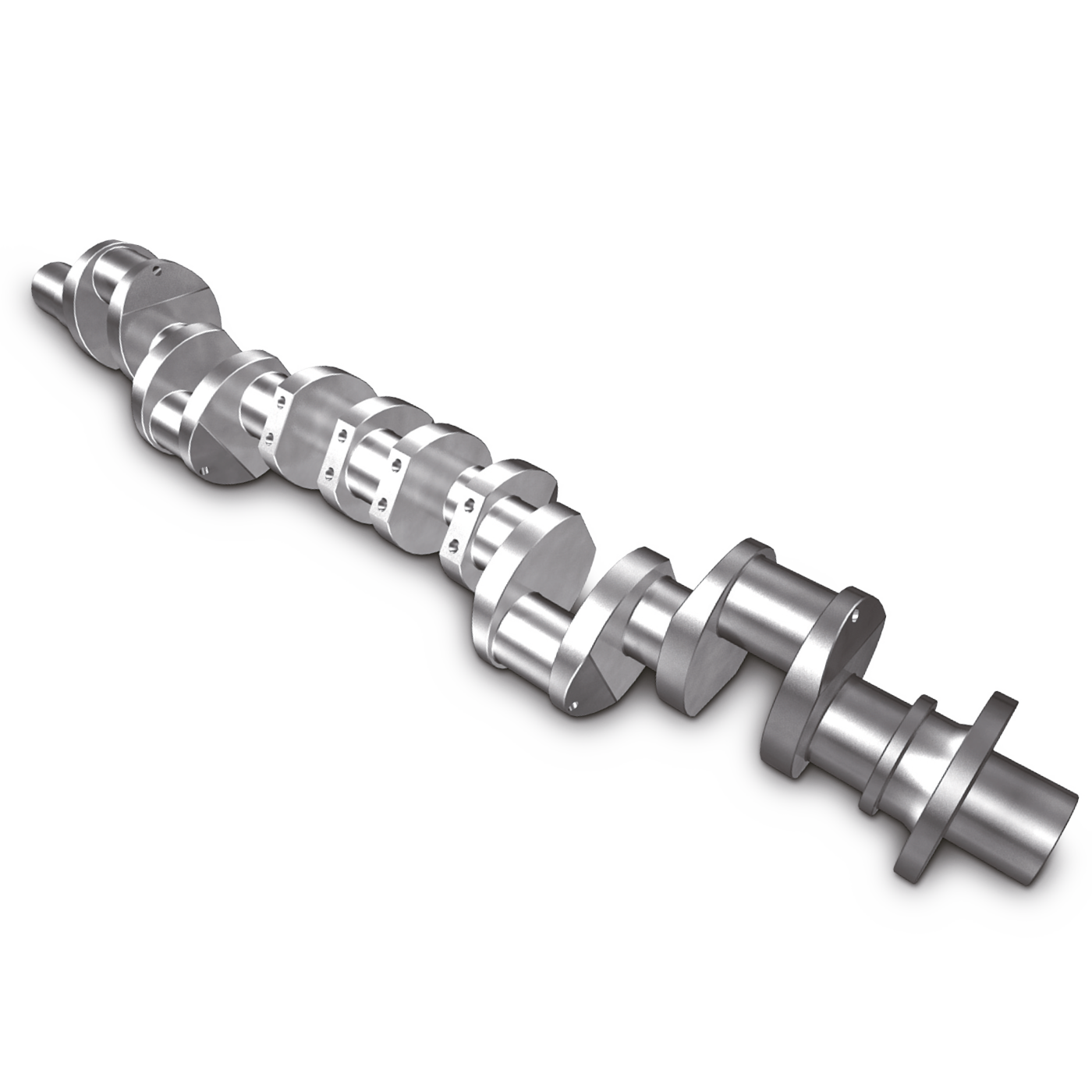

Crank shaft (coating)

- Cobalt alloy

- Marine

- ø 600 × 3,200 mm

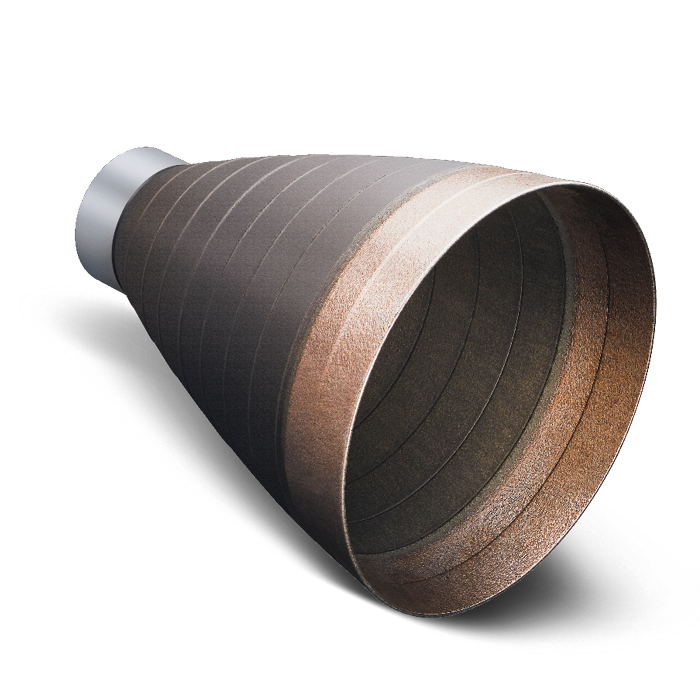

Rocket nozzle

- SUS316L

- Aerospace

- ø 450 × 470 mm

DED hybrid on 5-axis turn-mill and 5-axis universal milling machines

NTX / NT & DED hybrid

Turning, Milling and Additive Manufacturing on 5-axis Turn-Mill machines

- LASERTEC 3000 DED hybrid: Workpieces up to ø 670 × 1,519 mm

- LASERTEC 6600 DED hybrid: Workpieces up to ø 1,010 × 3,702 mm

- Tool magazine for up to 3 different AM laser nozzles

- 6-sided complete machining of components at the main and counter spindles with subsequent welding of the built components

- Milling machining: B-axis with compactMASTER turning-milling spindle up to 20,000 rpm and 132 Nm

(LASERTEC 6600 DED hybrid: turn & mill spindle with 8,000 rpm and 302 Nm) - Turning at the main and counter spindles

monoBLOCK & DED hybrid

Milling and Additive Manufacturing on 5-axis universal milling machines

- LASERTEC 65 DED hybrid Workpieces up to ø 500 × 400 mm // 600 kg

- LASERTEC 125 DED hybrid Workpieces up to ø 1,250 × 745 mm // 2,000 kg

- Milling: speedMASTER spindles up to 20,000 rpm and 130 Nm

- 5-axis machining: NC swivelling rotary table with A-axis: +120°/-120 and 360° C-axis

- Mill-turning option for the LASERTEC 65 DED hybrid for integrated turning up to 1,200 rpm

Supporting technologies

AM Assistant

- AM Assistant for excellent process reliability and comprehensive traceability, as well as powder feed rate sensor and automatic powder calibration

- Integrated thermal imaging camera for observation of the whole working area, adaptive process control and constant monitoring of the working distance

AM Evaluator

Visualisation of the relevant process data (e. g. meltpool size, powder mass flow) as a digital 3D-model as well as in the chronological sequence

Siemens NX

Hybrid CAD / CAM module for programming additive and subtractive machining.

Mill & Turn (FD)

Turning on 5-axis milling machines

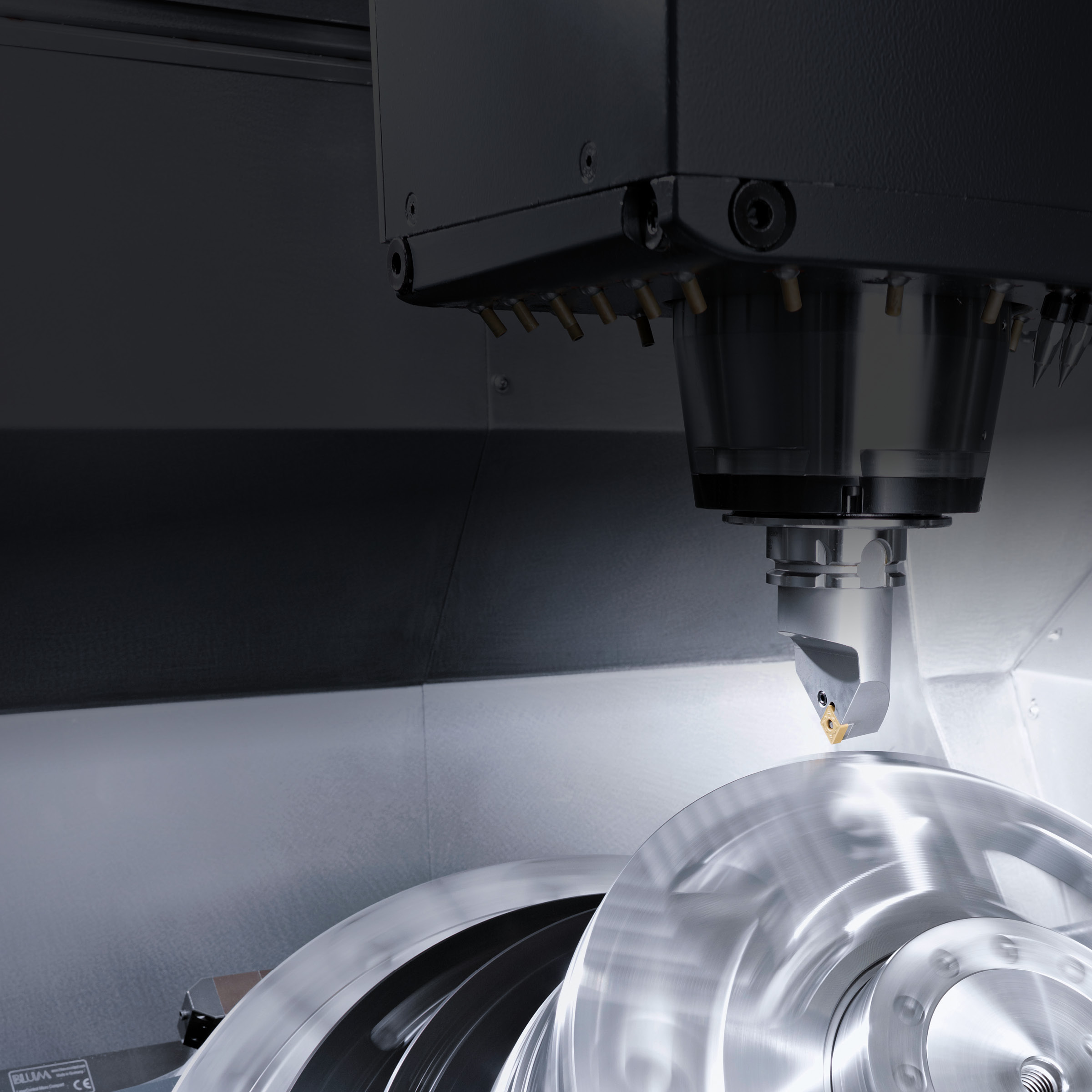

Turn & Mill

6-sided complete machining by turning and milling

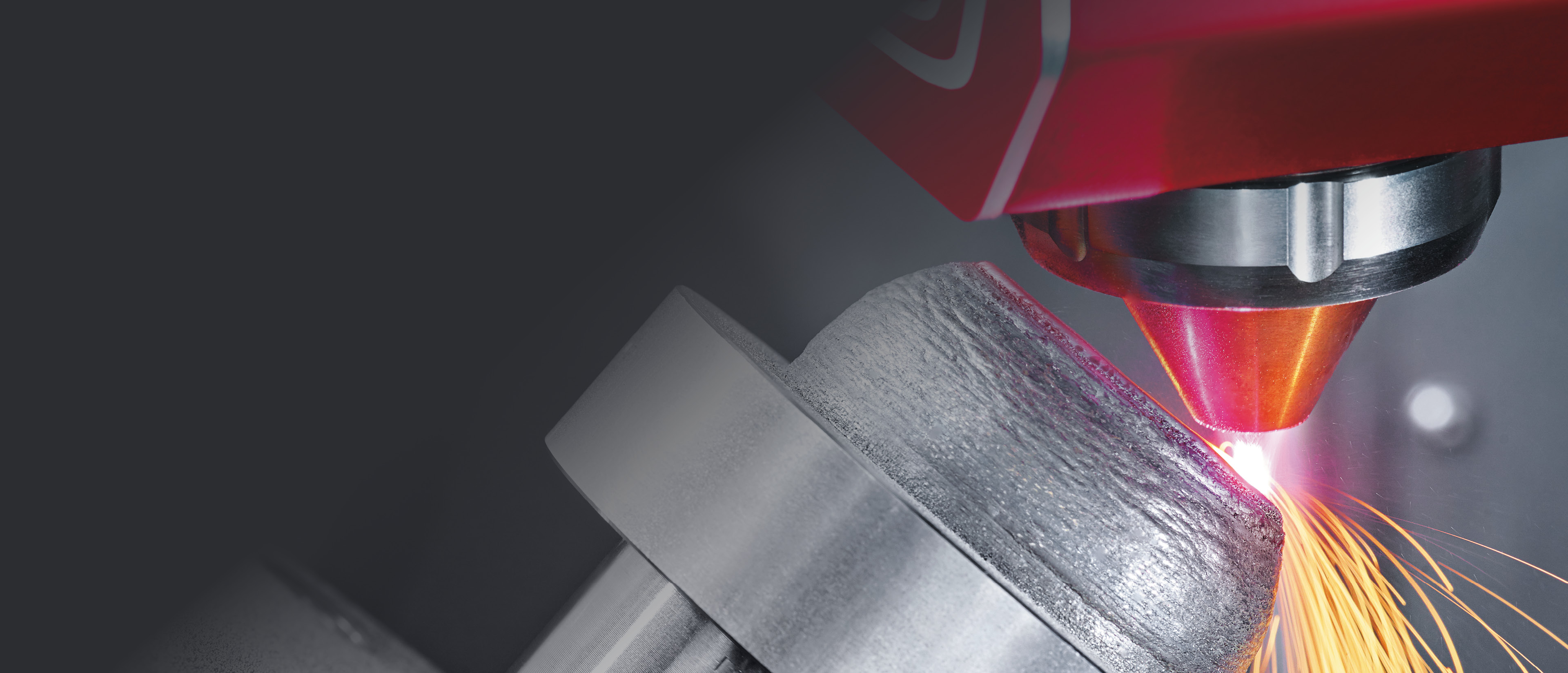

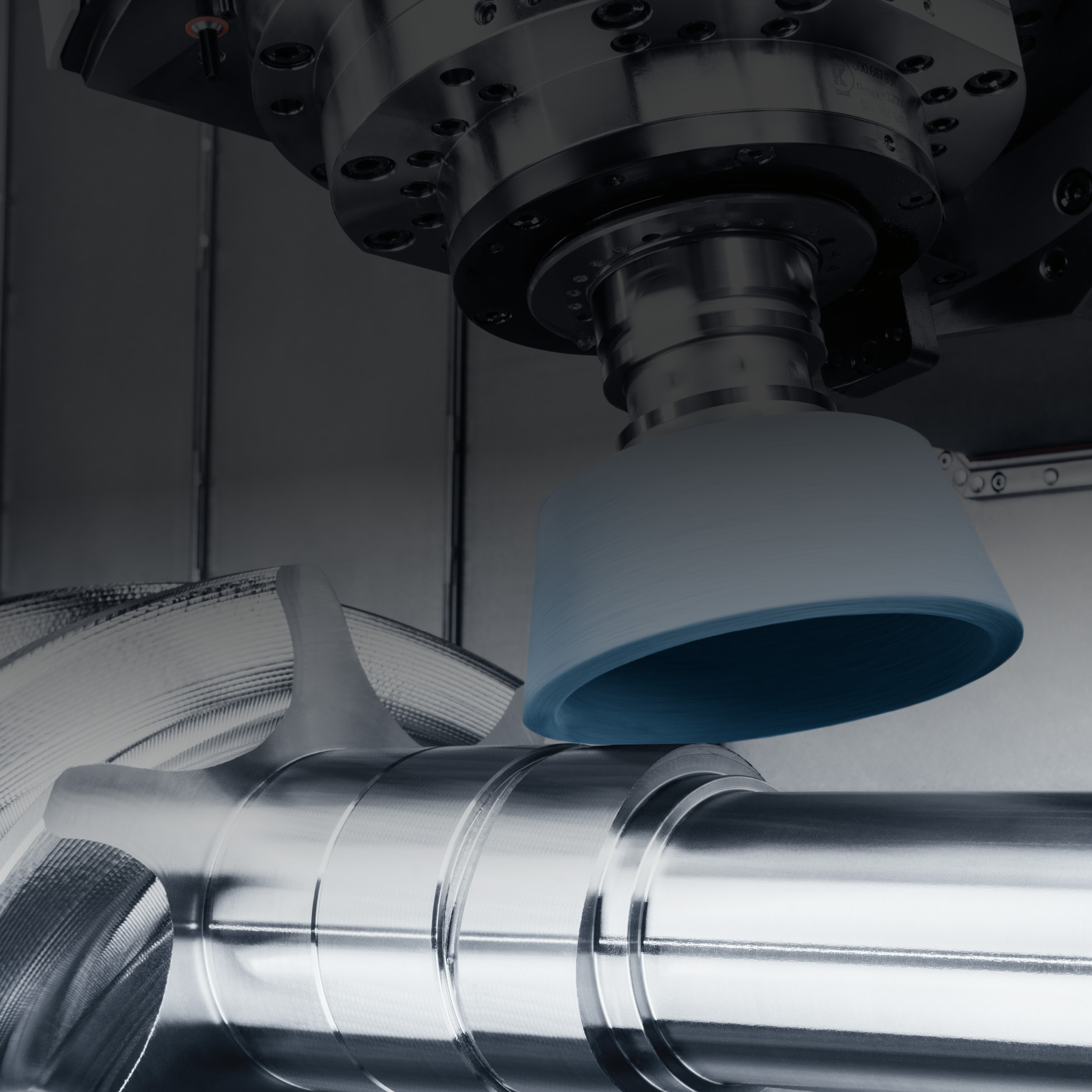

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

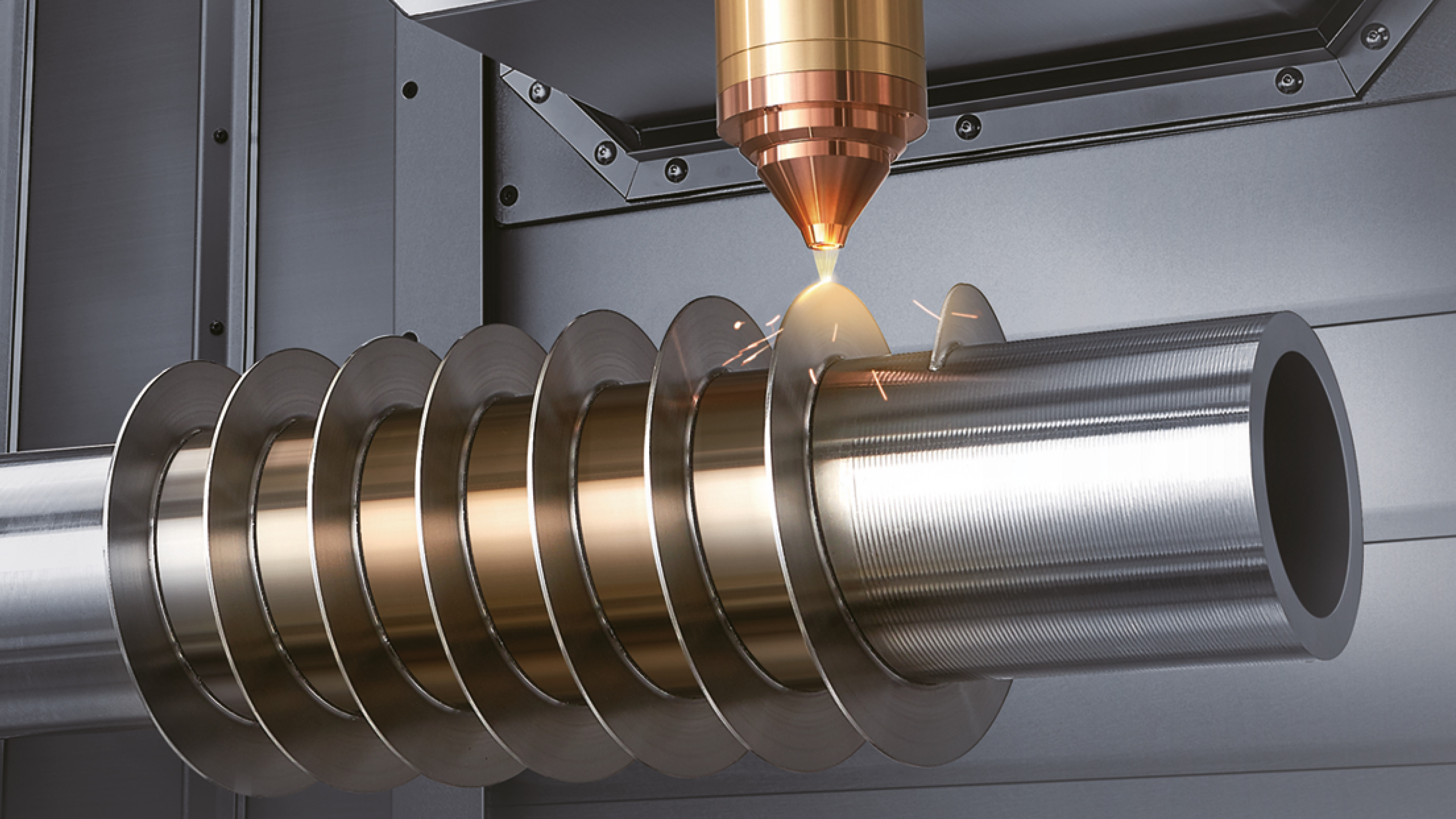

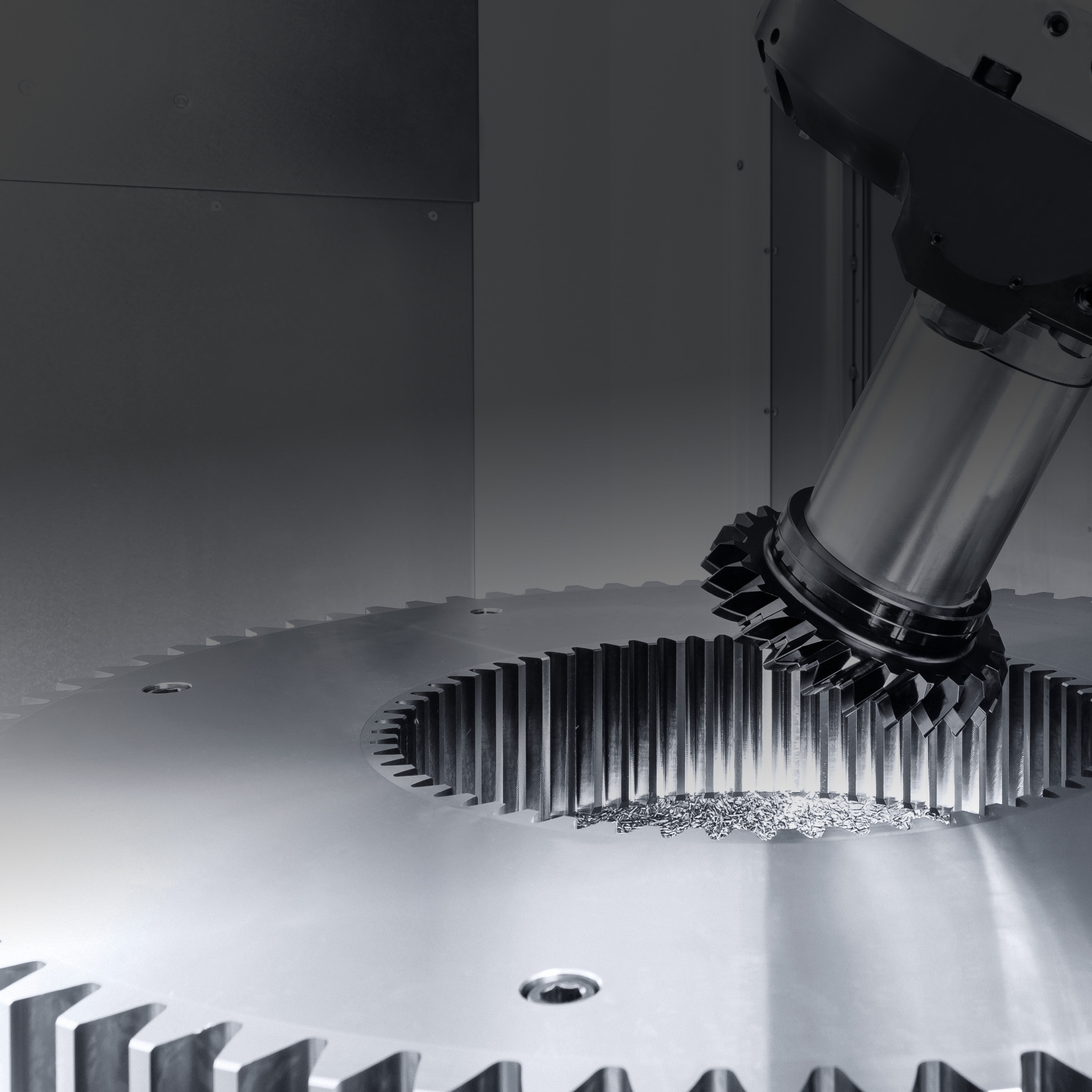

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

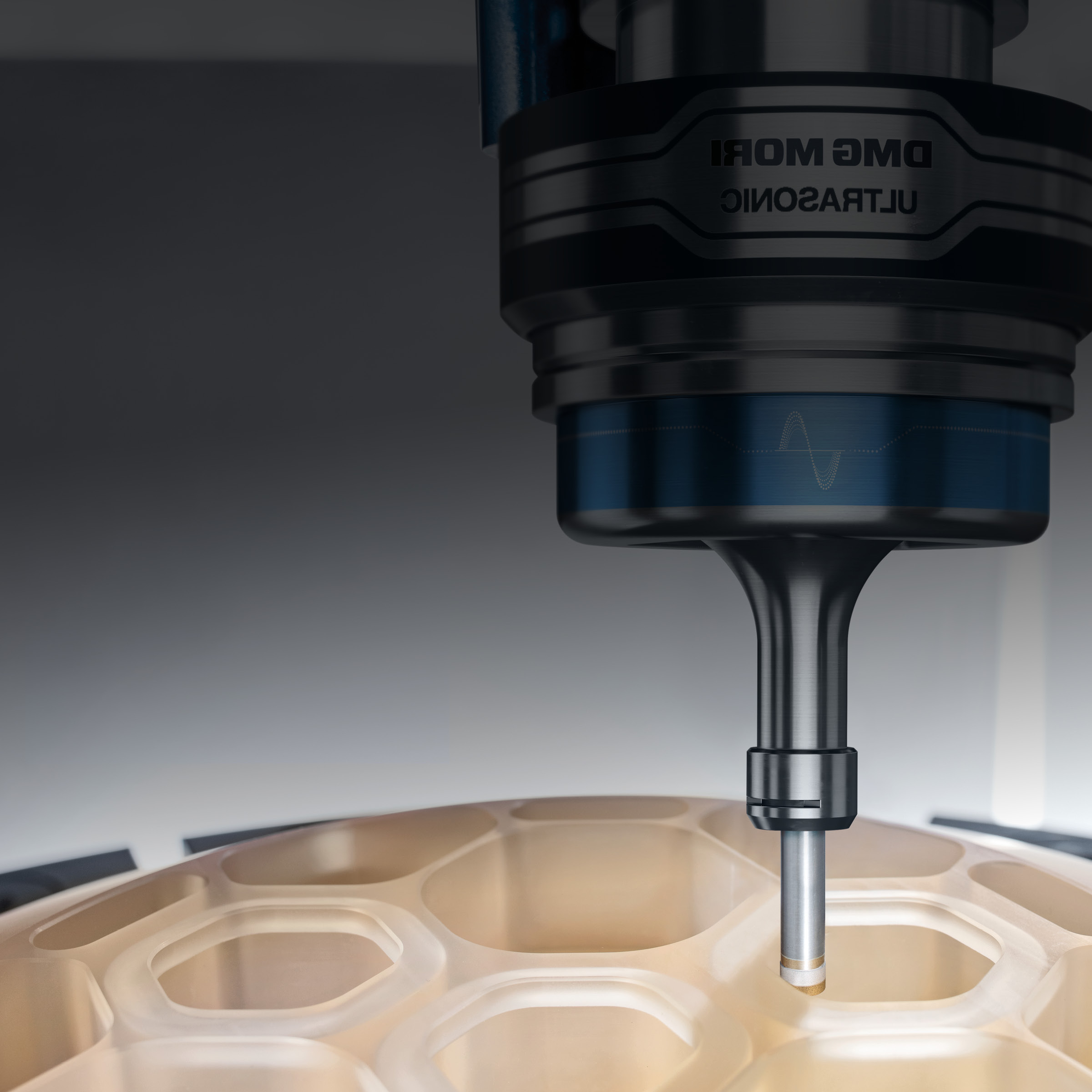

ULTRASONIC

Reduced process forces for very high productivity

LASERTEC

Contact-free 5-axis laser machining

Additive Manufacturing DED hybrid

Milling, Turning and Additive Manufacturing on

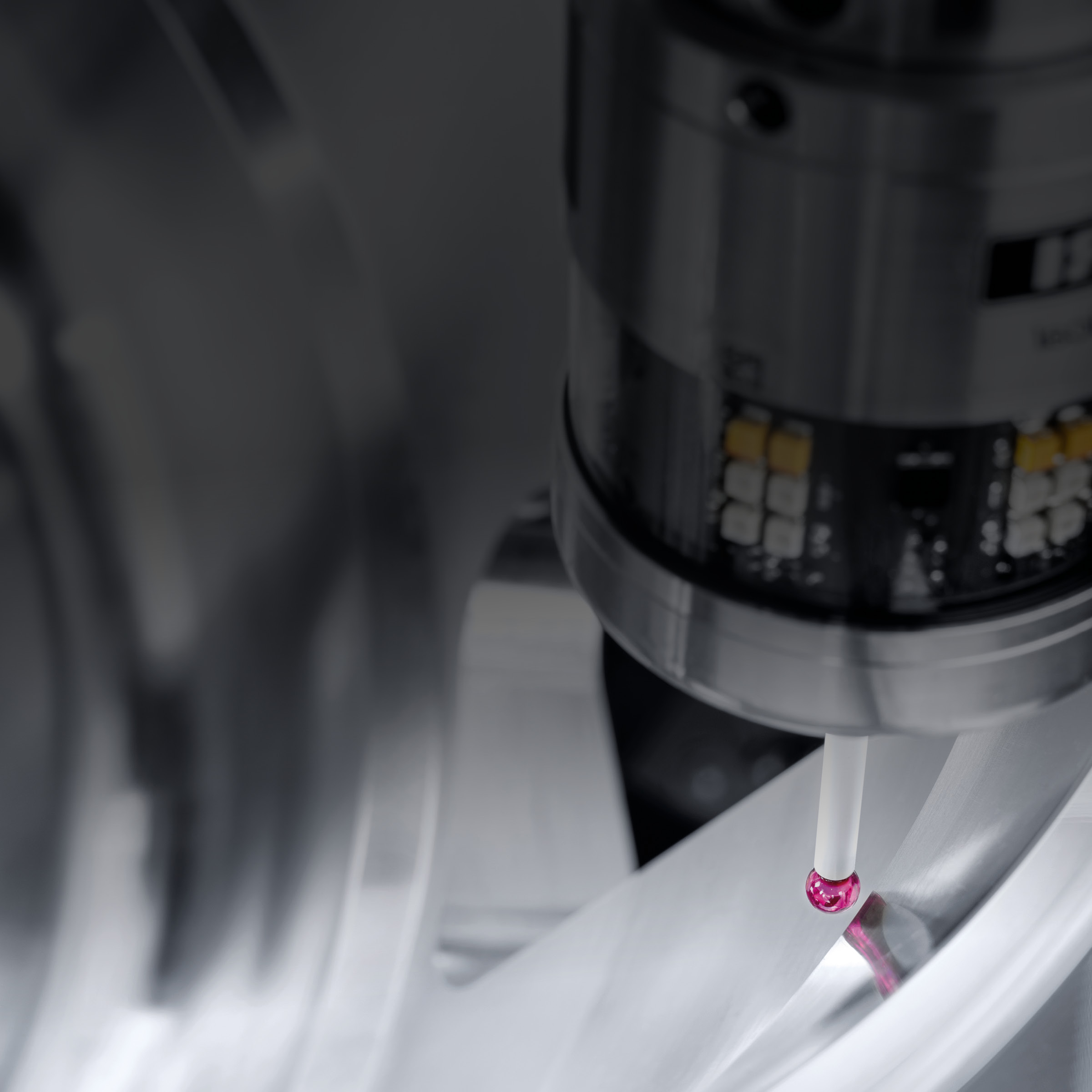

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Or call us!

Or call us!