Integrated processes

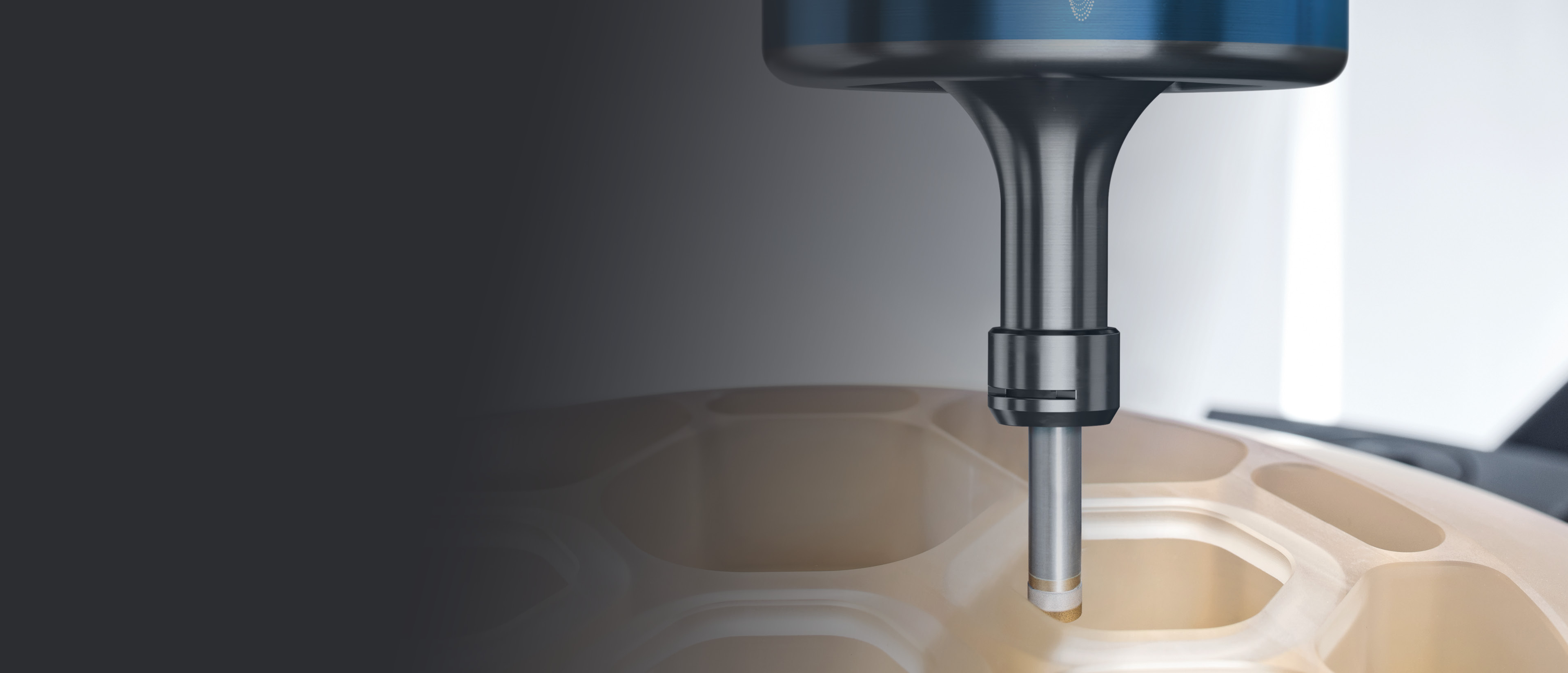

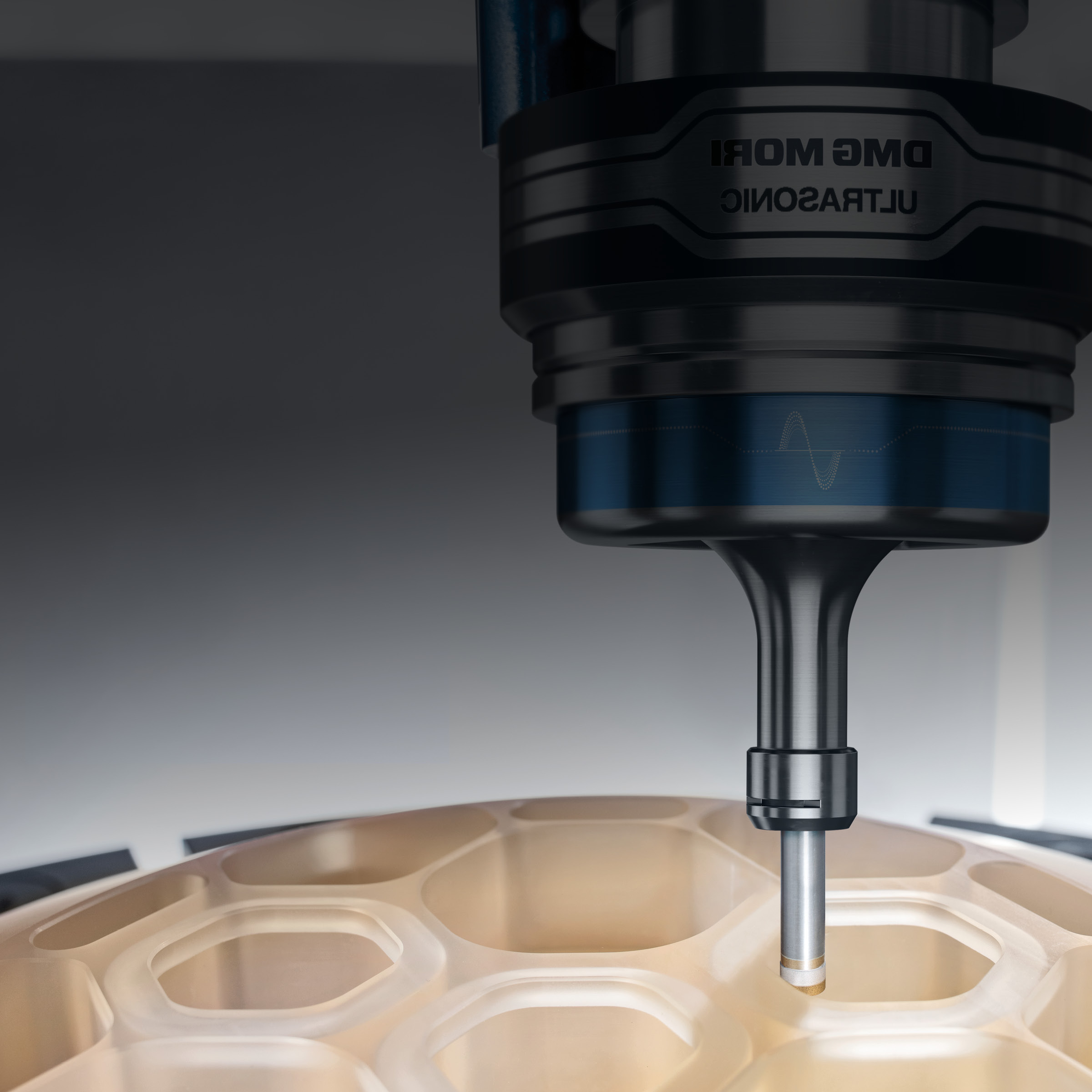

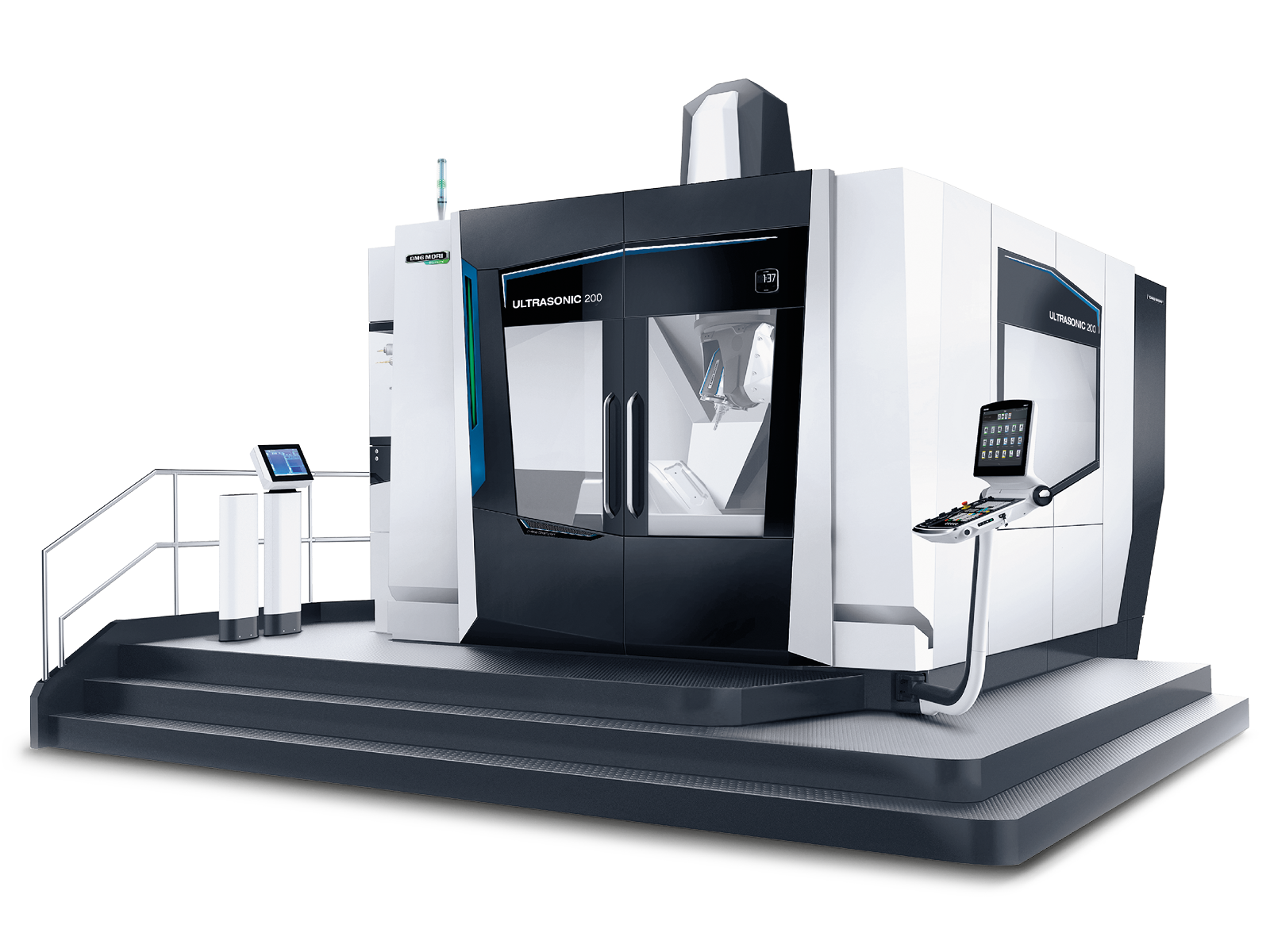

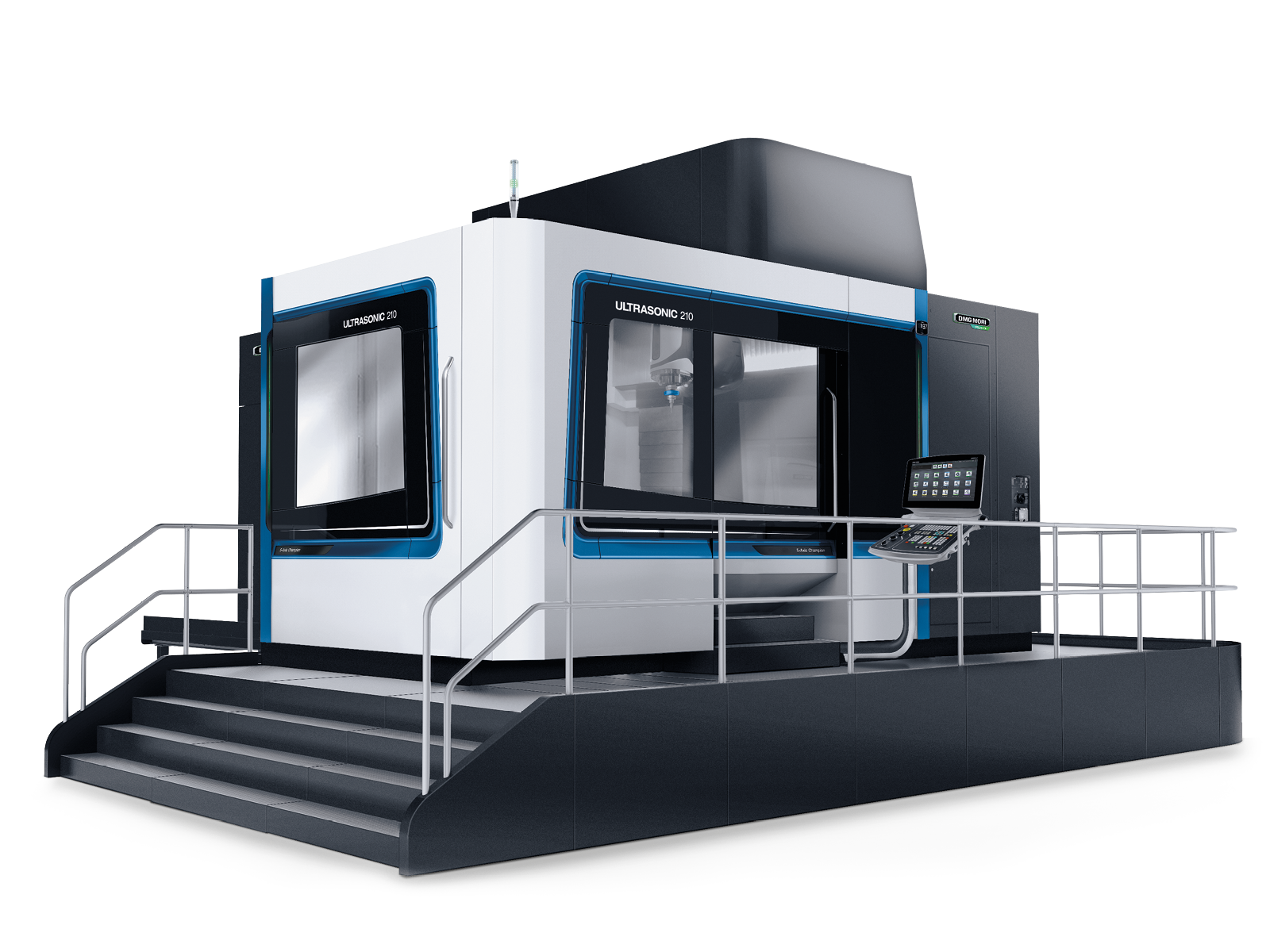

ULTRASONIC

Reduced process forces for very high productivity

Highlights

- Ideal for machining of complex workpiece geometries in hard and brittle advanced materials like e. g. ceramics, glass, corundum, carbide or composites

- Up to 50% lower process forces due to ULTRASONIC

- Up to 40 % less sub-surface damage (SSD)

- Up to 3 times higher productivity

- Surface quality to Ra ≤ 0.1 µm is possible

- Integration via HSK interface. All standard machine features for milling / turning are possible.

Workpieces

Mirror support

- Zerodur

- Optical industry

- ø 400 × 150 mm

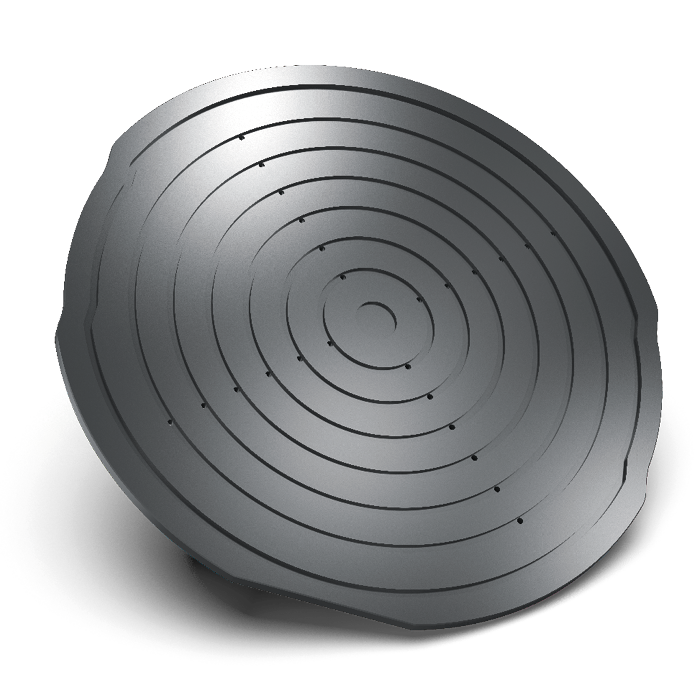

Wafer chuck

- SiC

- Semiconductor

- ø 300 × 6 mm

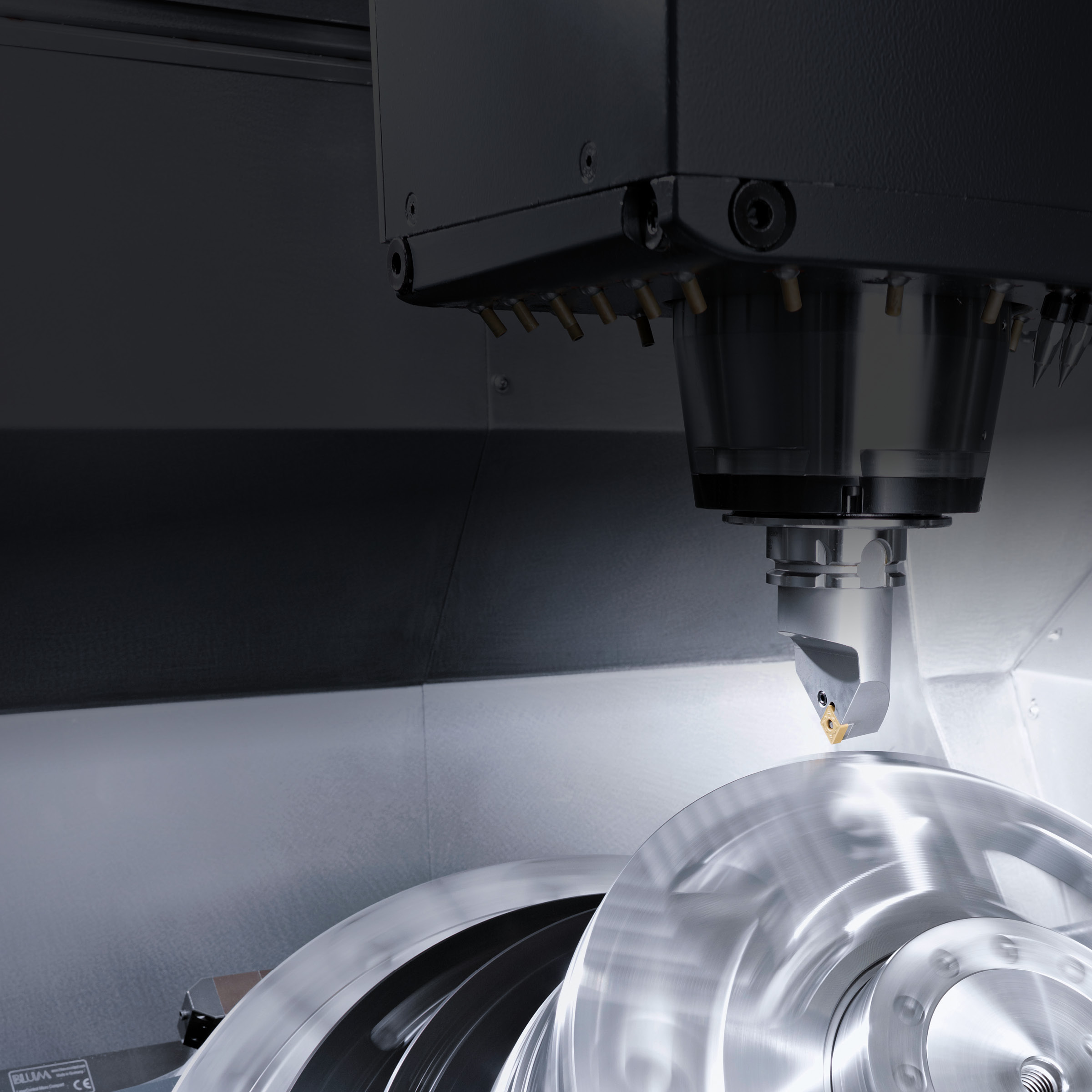

Blades

- Composite (CMC)

- Aerospace

- 50 × 150 × 195 mm

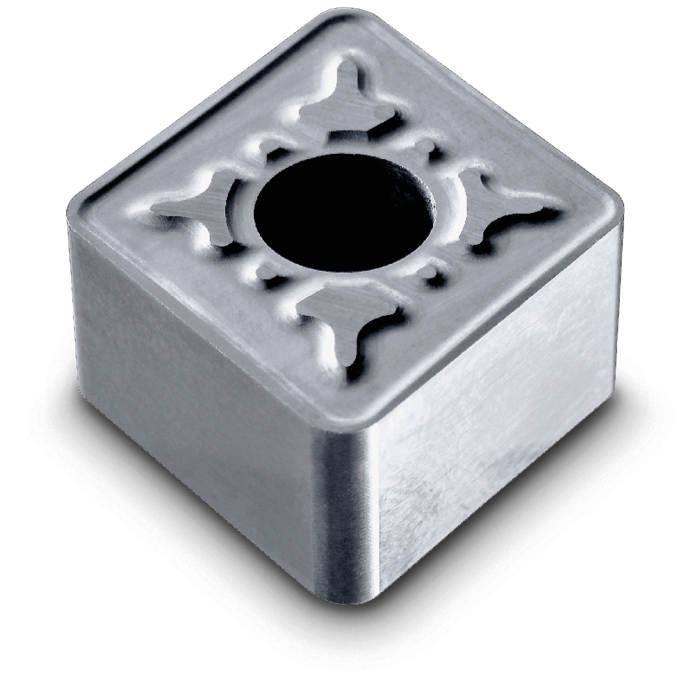

Indexable insert

- Carbide

- Tooling

- 15 × 20 × 8 mm

Technologies

ULTRASONIC microDRILL

- Adaptive spindle with max. 32,000 rpm

- Use of hollow- or spiral-drills starting from ø 0.1 mm

- Automatic drilling force regulation (<1 N)

- ICS with up to 40 bar and volume flow monitoring

- Automatic ejector for drill cores (with hollow drills) to avoid tool breakage

ULTRASONIC axialGRINDING

Highly efficient grinding of rotationally symmetrical structures in hard and brittle materials in combination with direct drive C-axis (option)

ULTRASONIC microSCOPE

Camera-based workpiece alignment and detection of hidden contours or marks in transparent material, e. g. aligning a glass cylinder with two marks, ideal for the semiconductor and optical industries.

Mill & Turn (FD)

Turning on 5-axis milling machines

Turn & Mill

6-sided complete machining by turning and milling

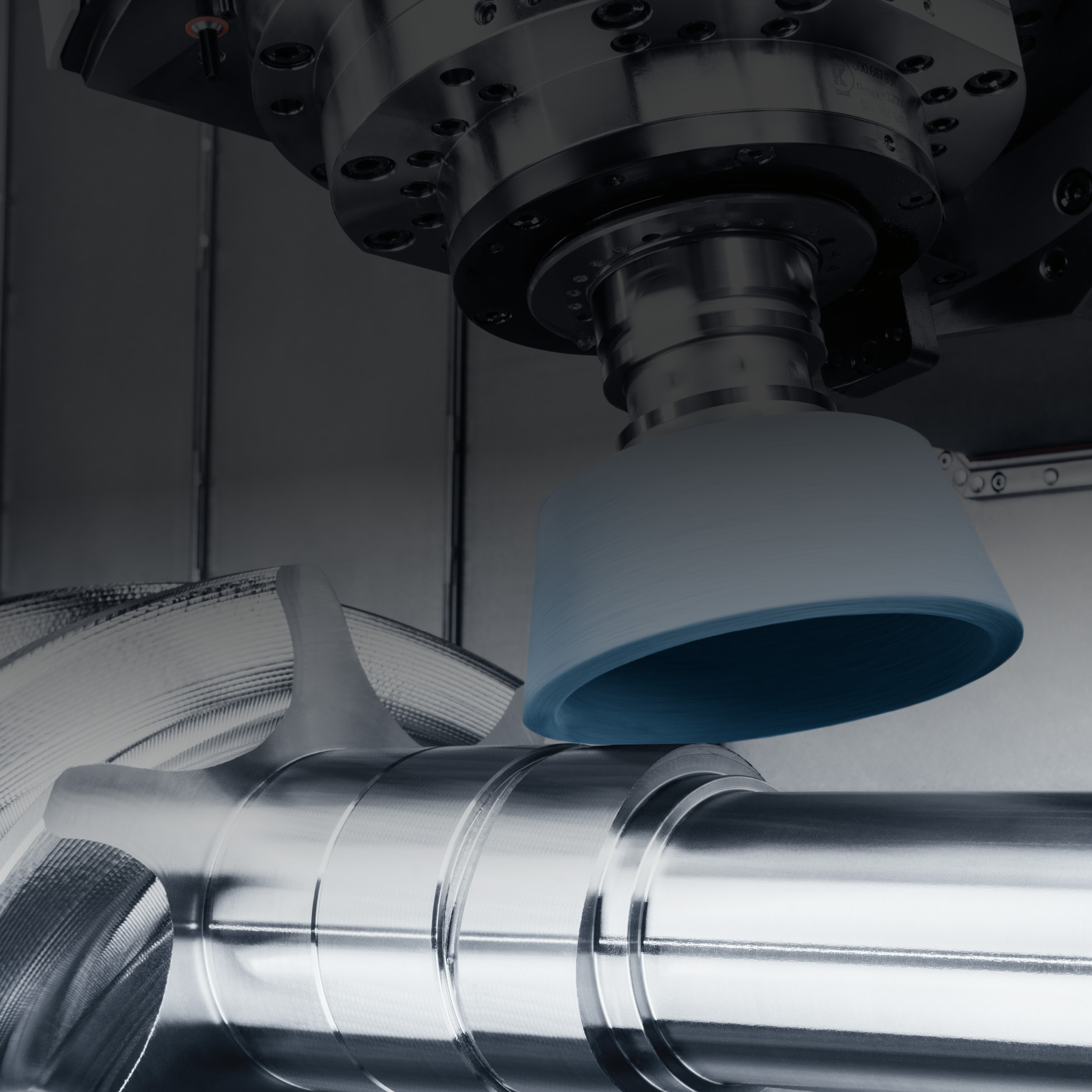

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

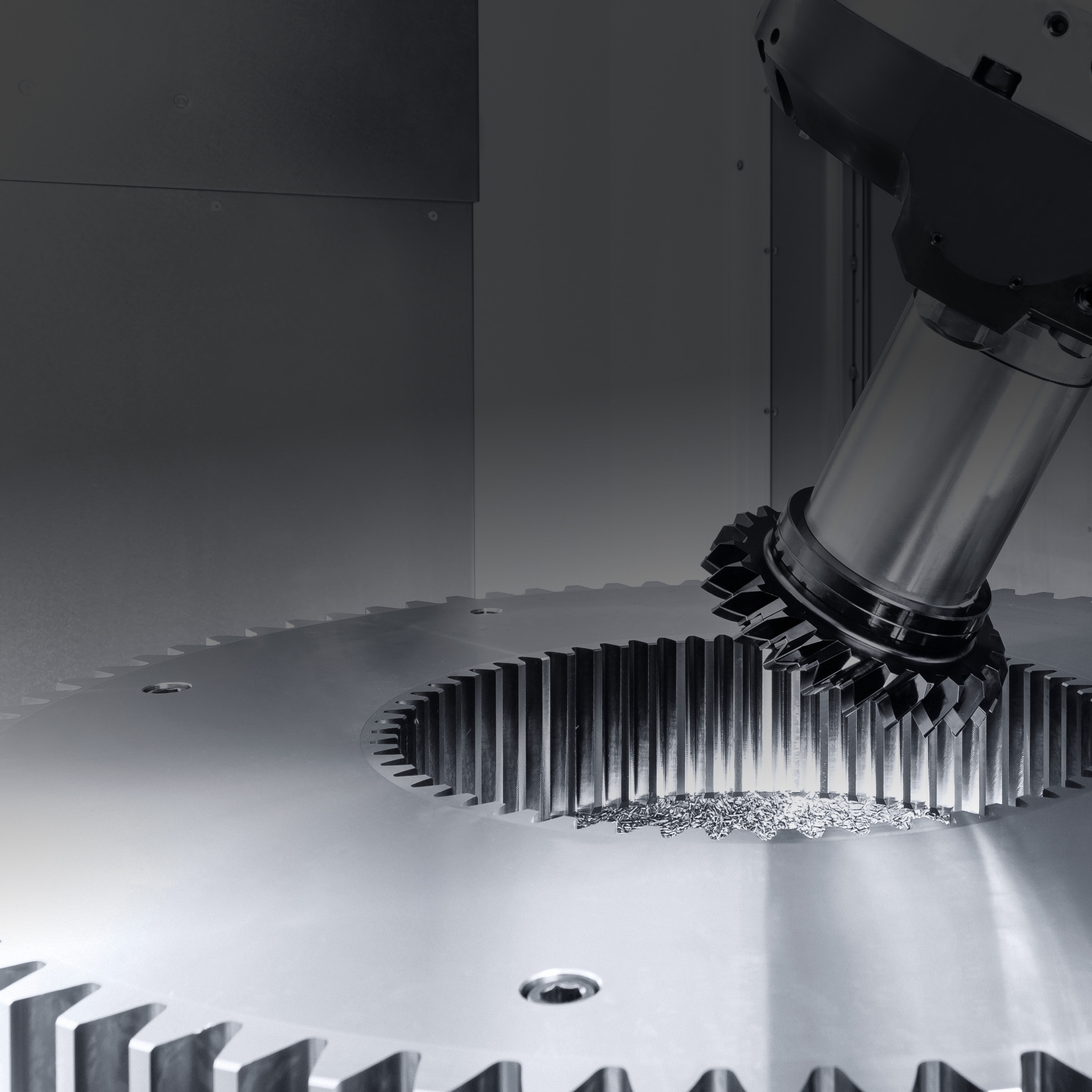

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

ULTRASONIC

Reduced process forces for very high productivity

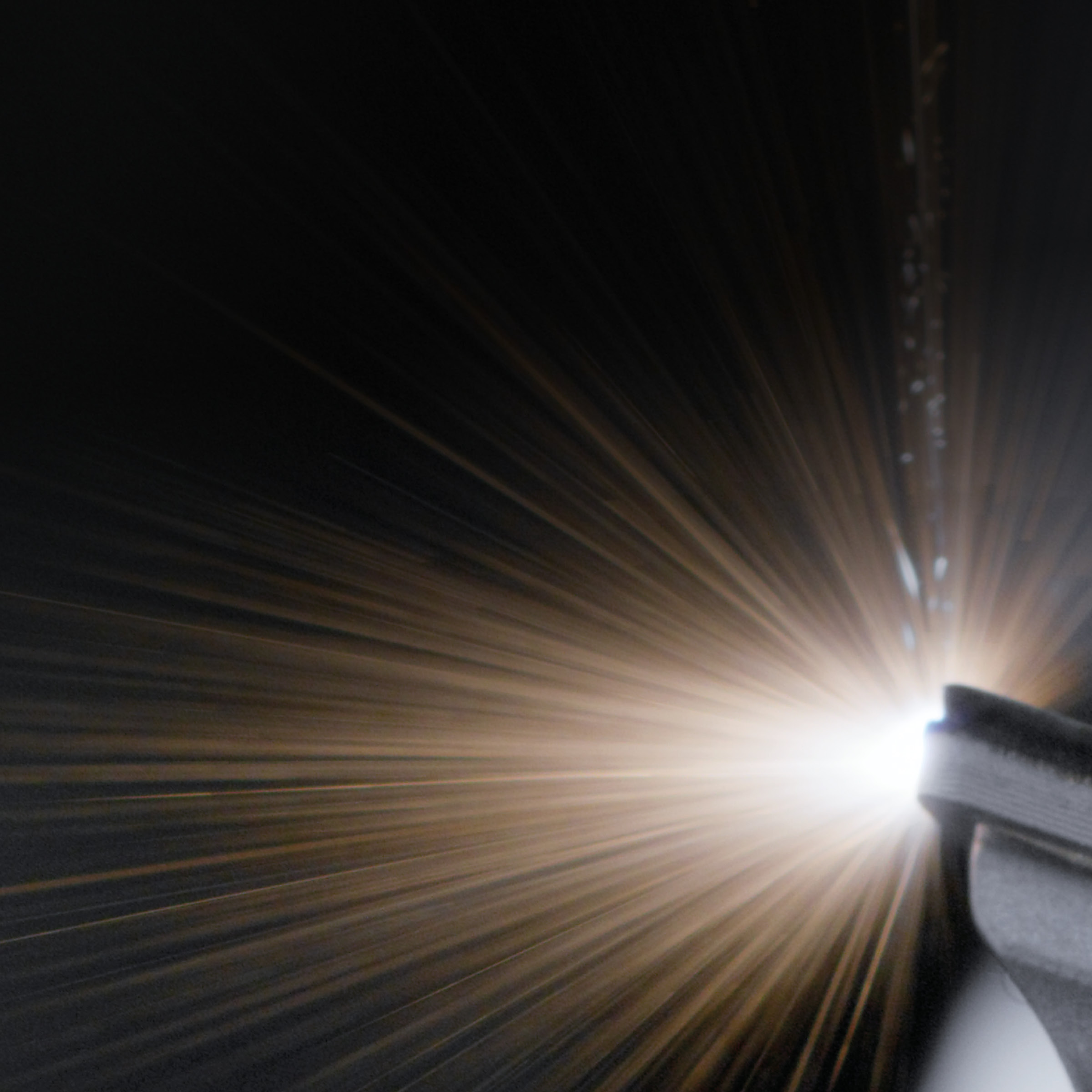

LASERTEC

Contact-free 5-axis laser machining

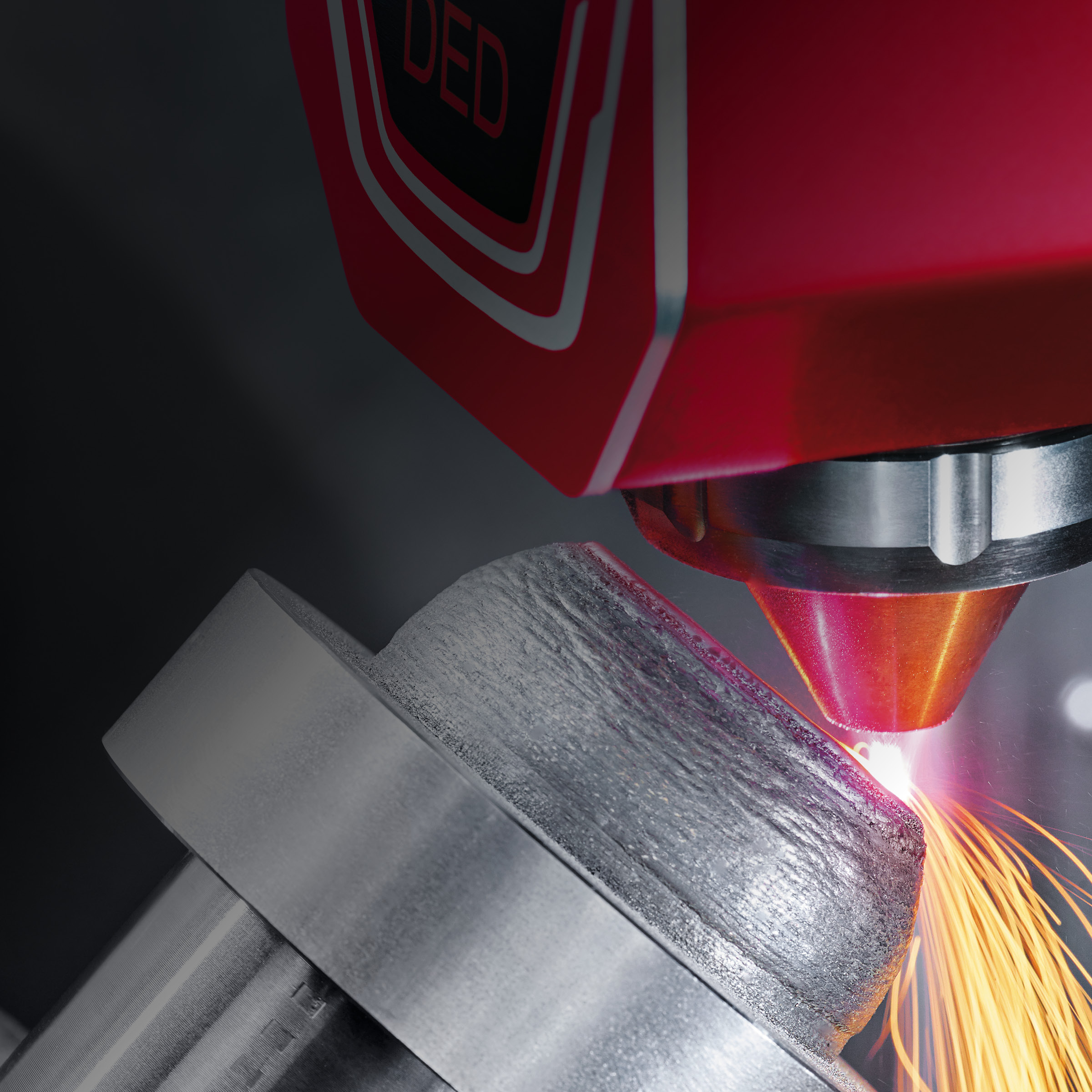

Additive Manufacturing DED hybrid

Milling, Turning and Additive Manufacturing on

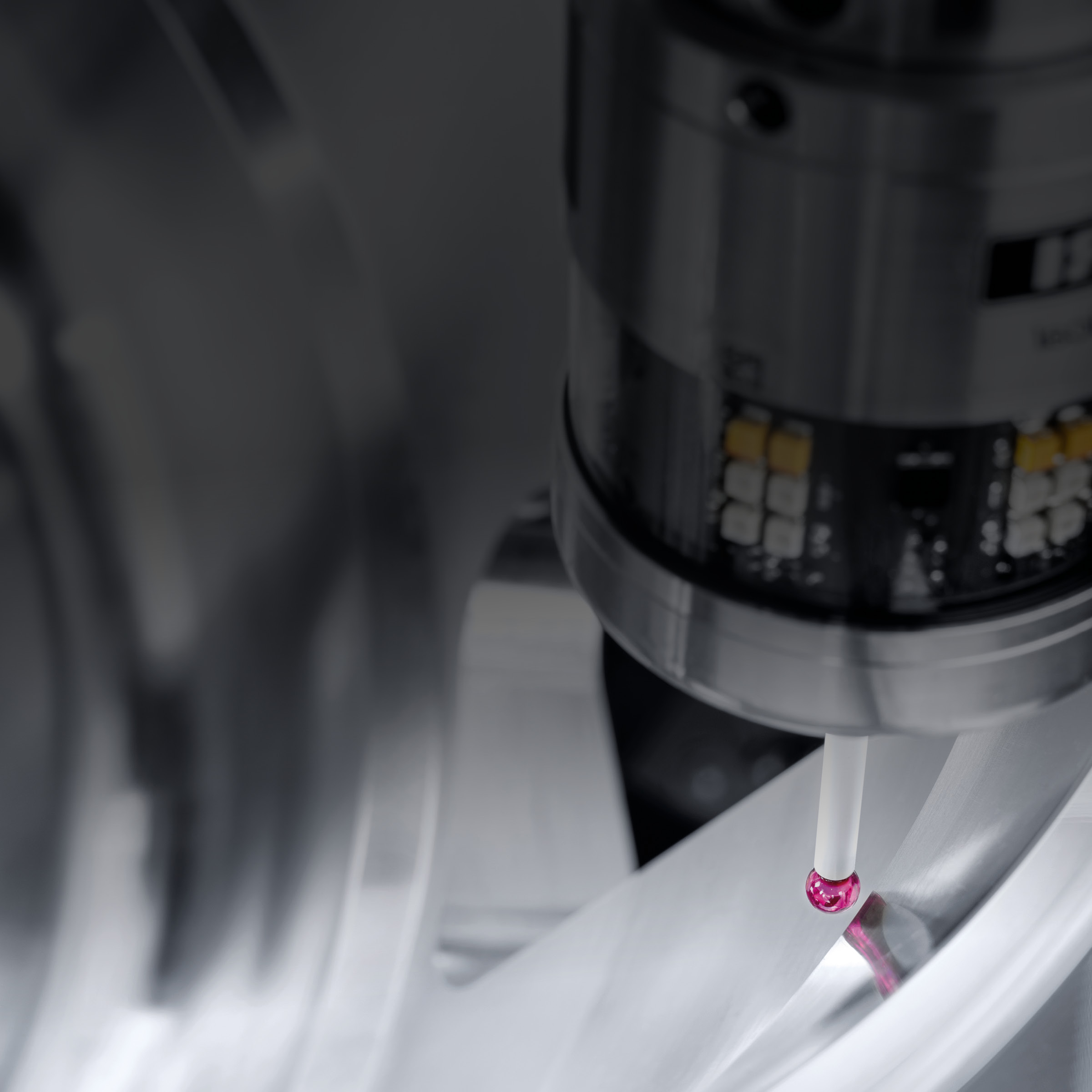

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Or call us!

Or call us!