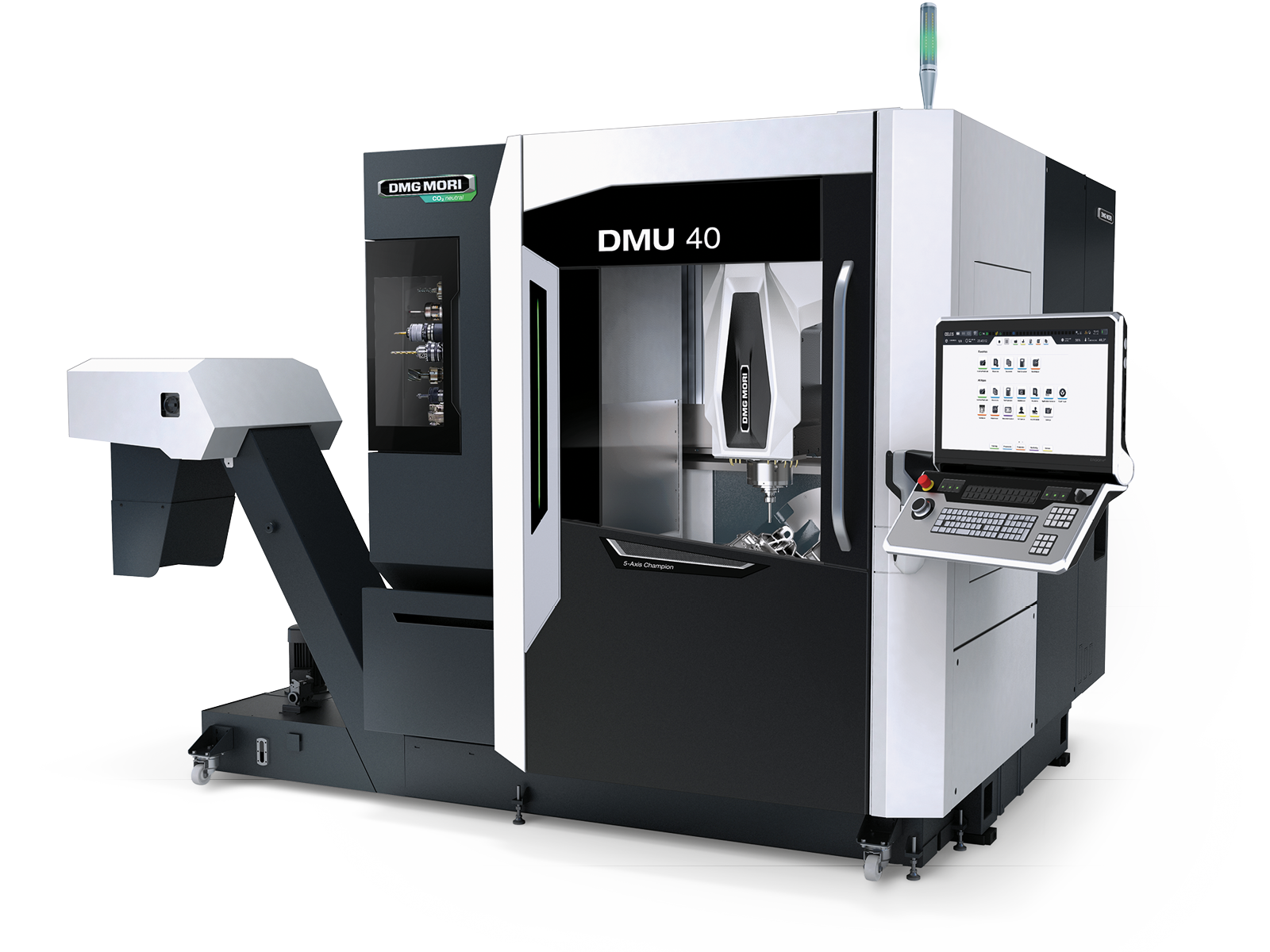

Integrated processes

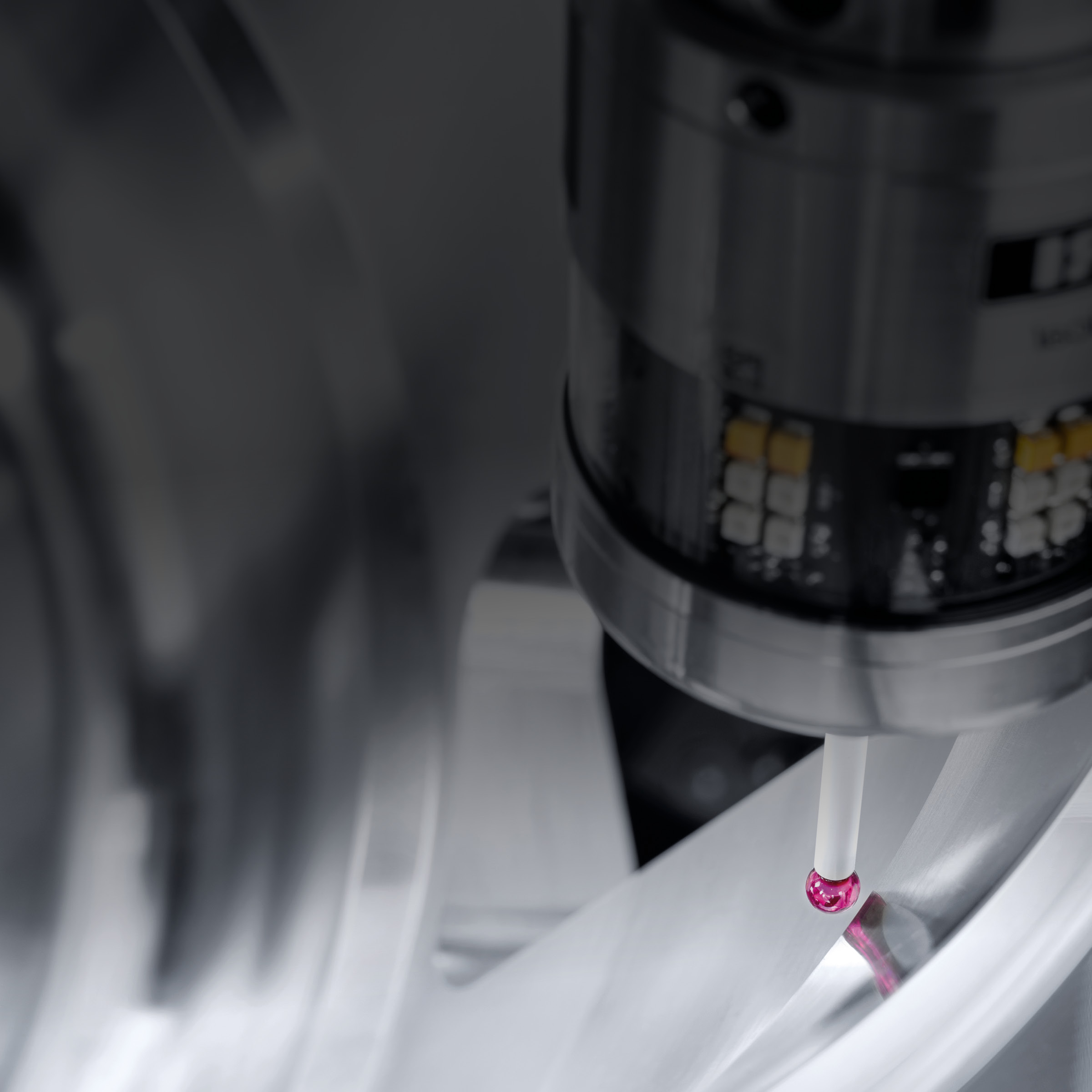

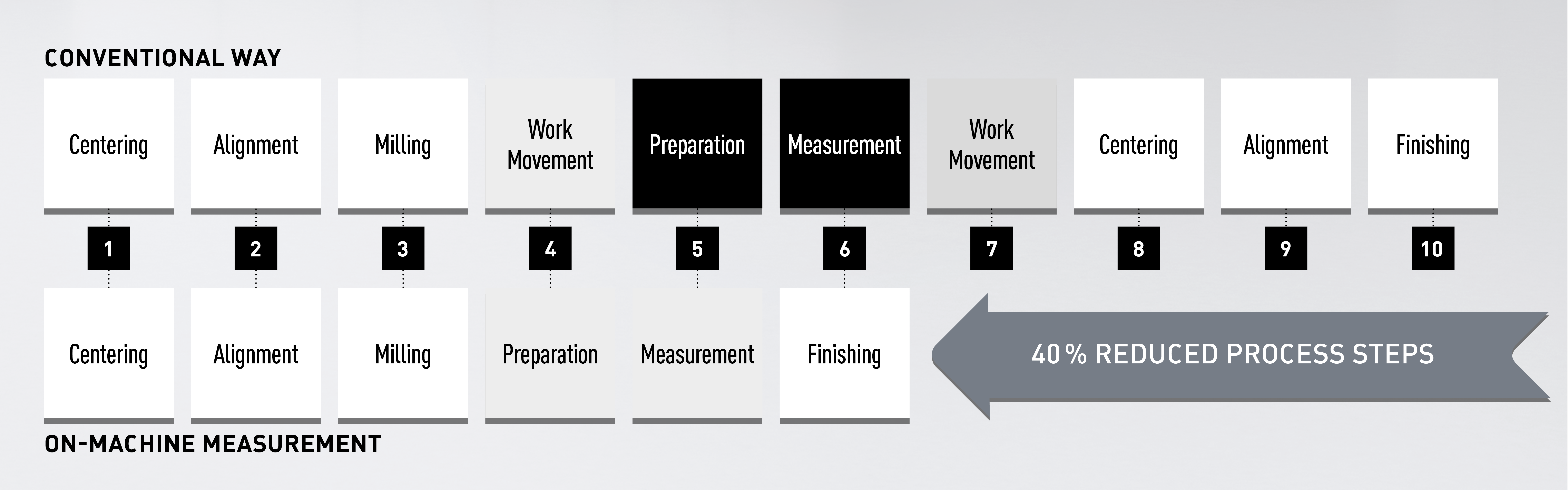

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Highlights

- Higher process stability and reliability due to process monitoring & control

- Integrated quality assurance

- Workpieces

- Tactile measurement of grooves / edges and diameters with up to 200 points, as well as surface roughness

- Optical measuring up to 70,000 scan points per second

-

Tools

- Tool measurement and drill breakage control

-

Adaptive measuring process

- Creation and integration of measuring operations into the CAM programming process

- DMG MORI technology measuring cycles

Facts

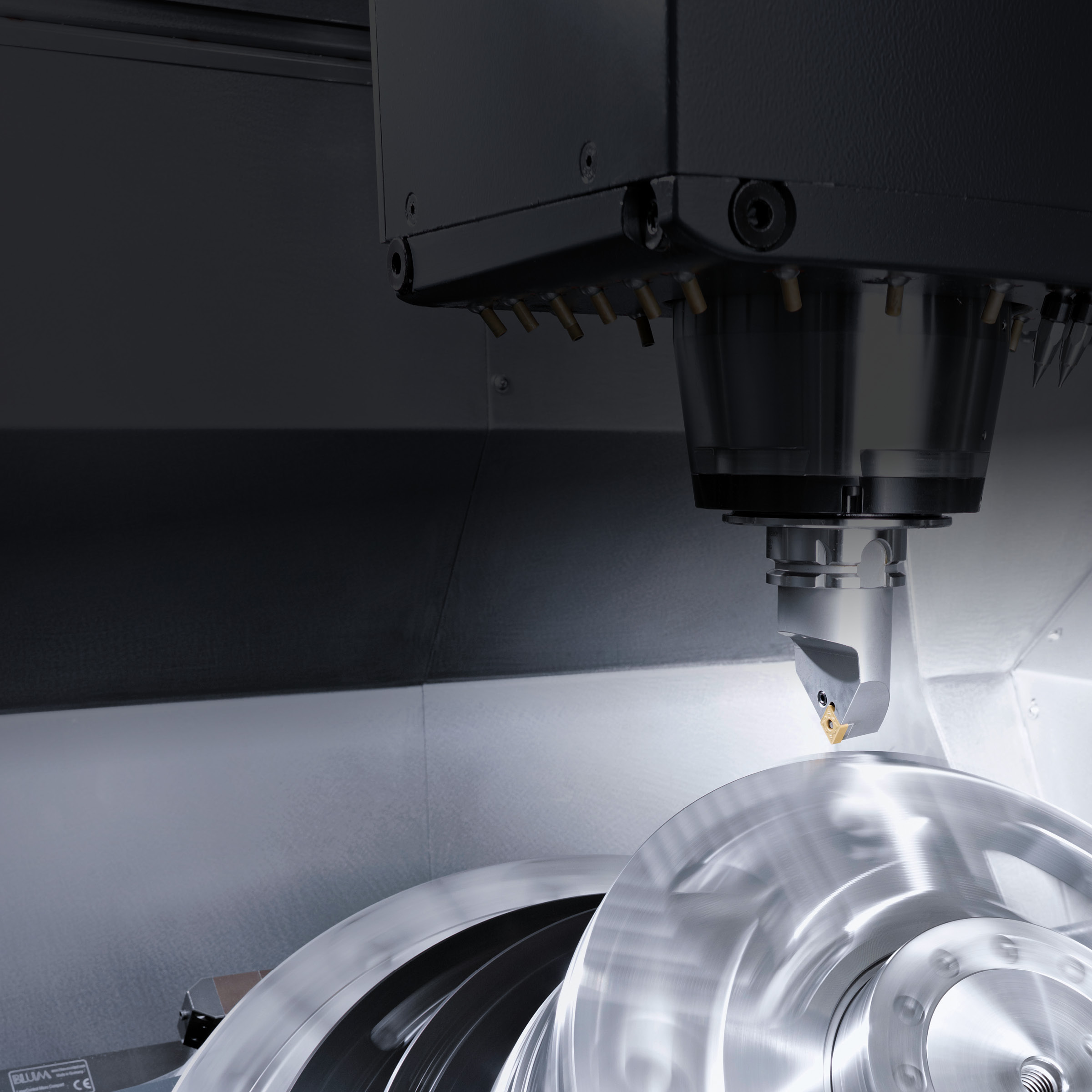

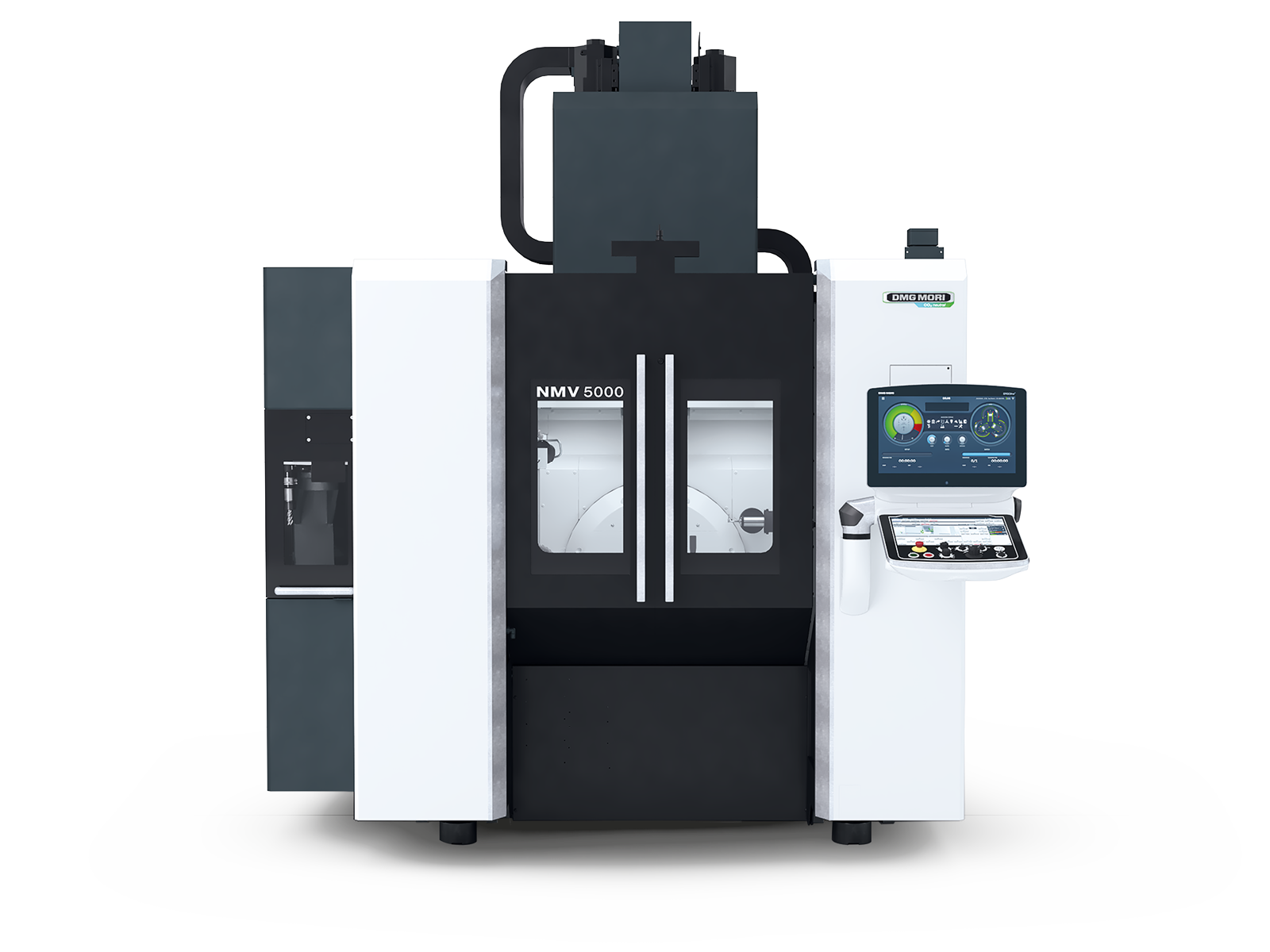

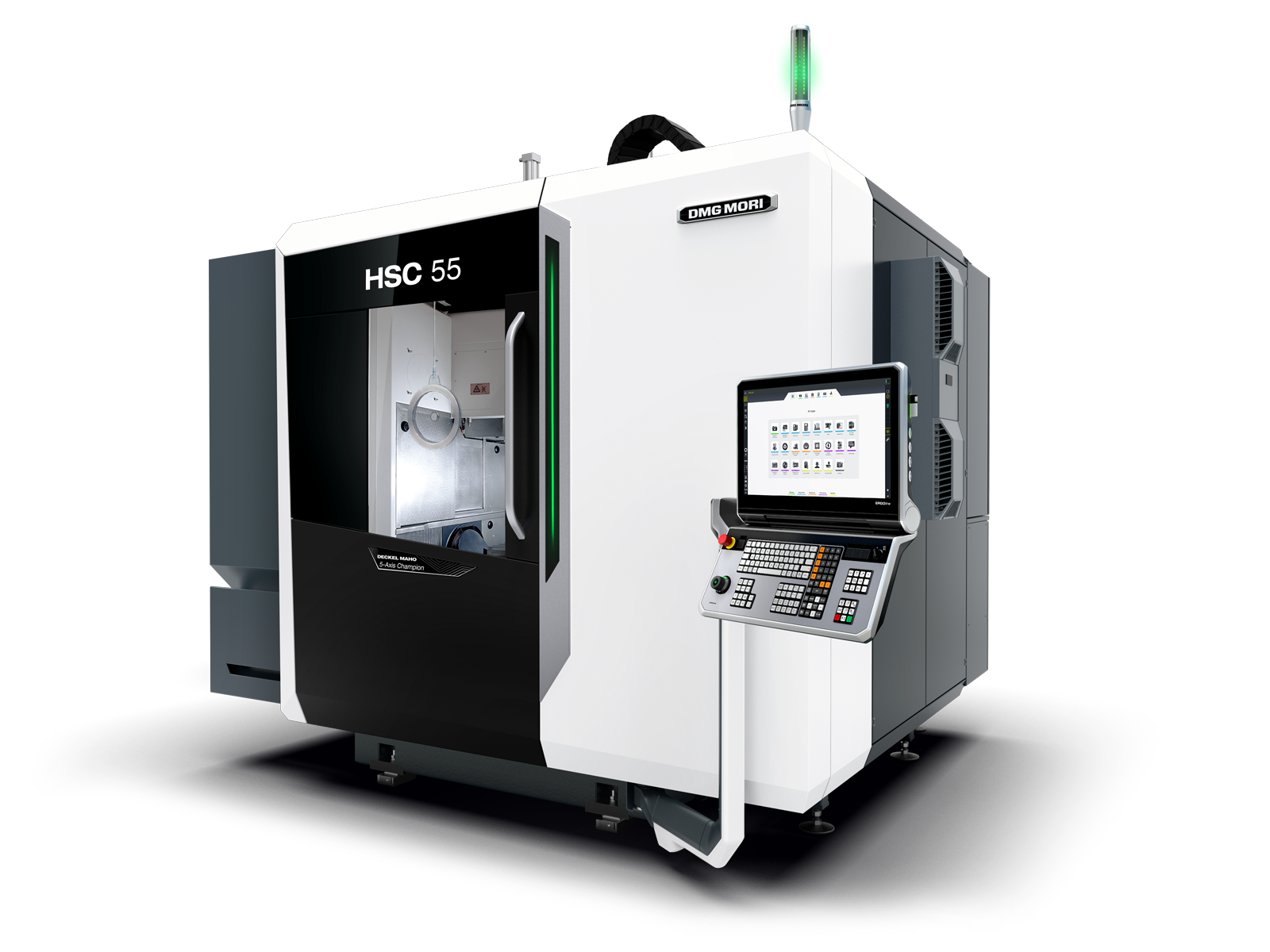

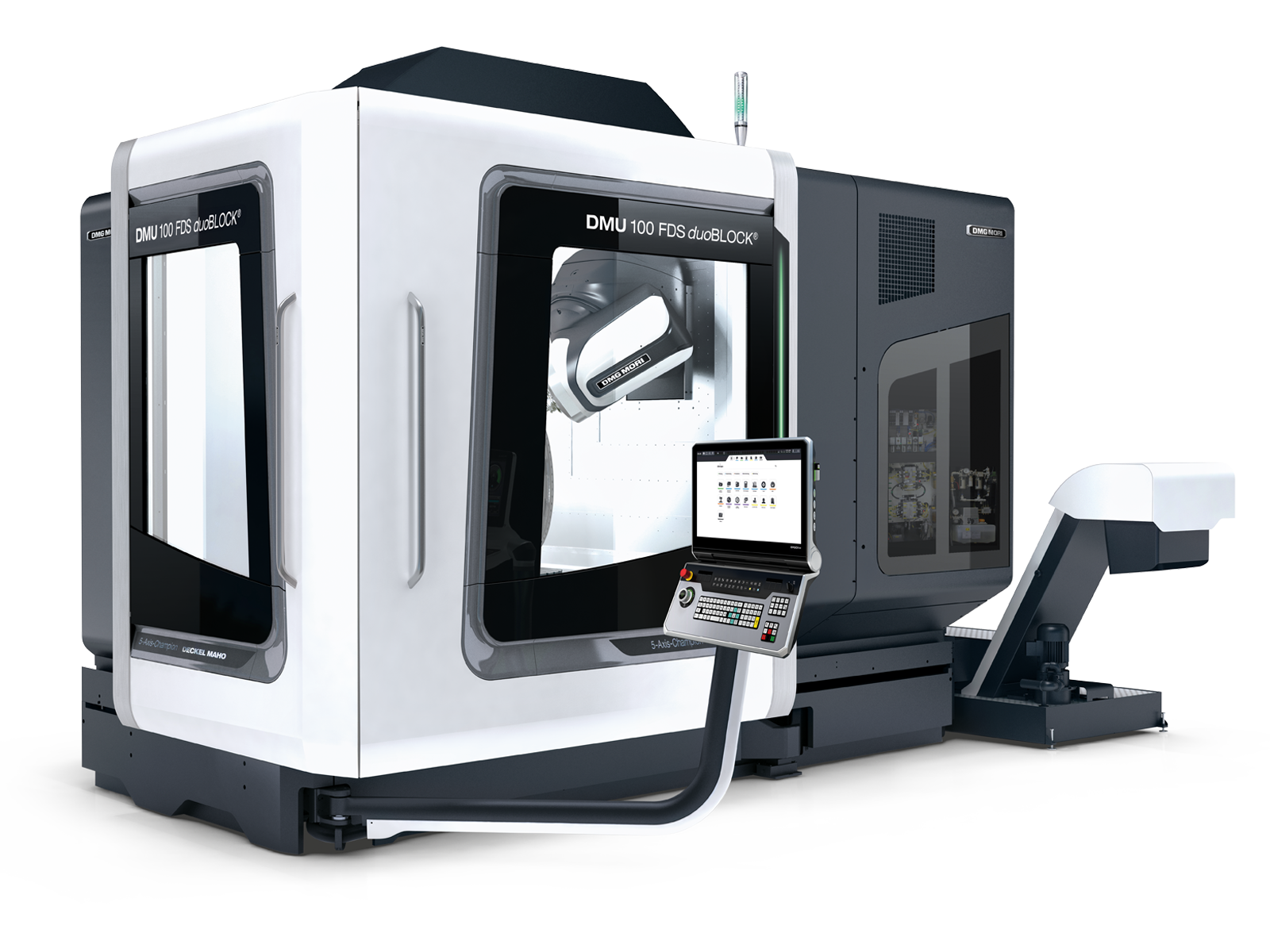

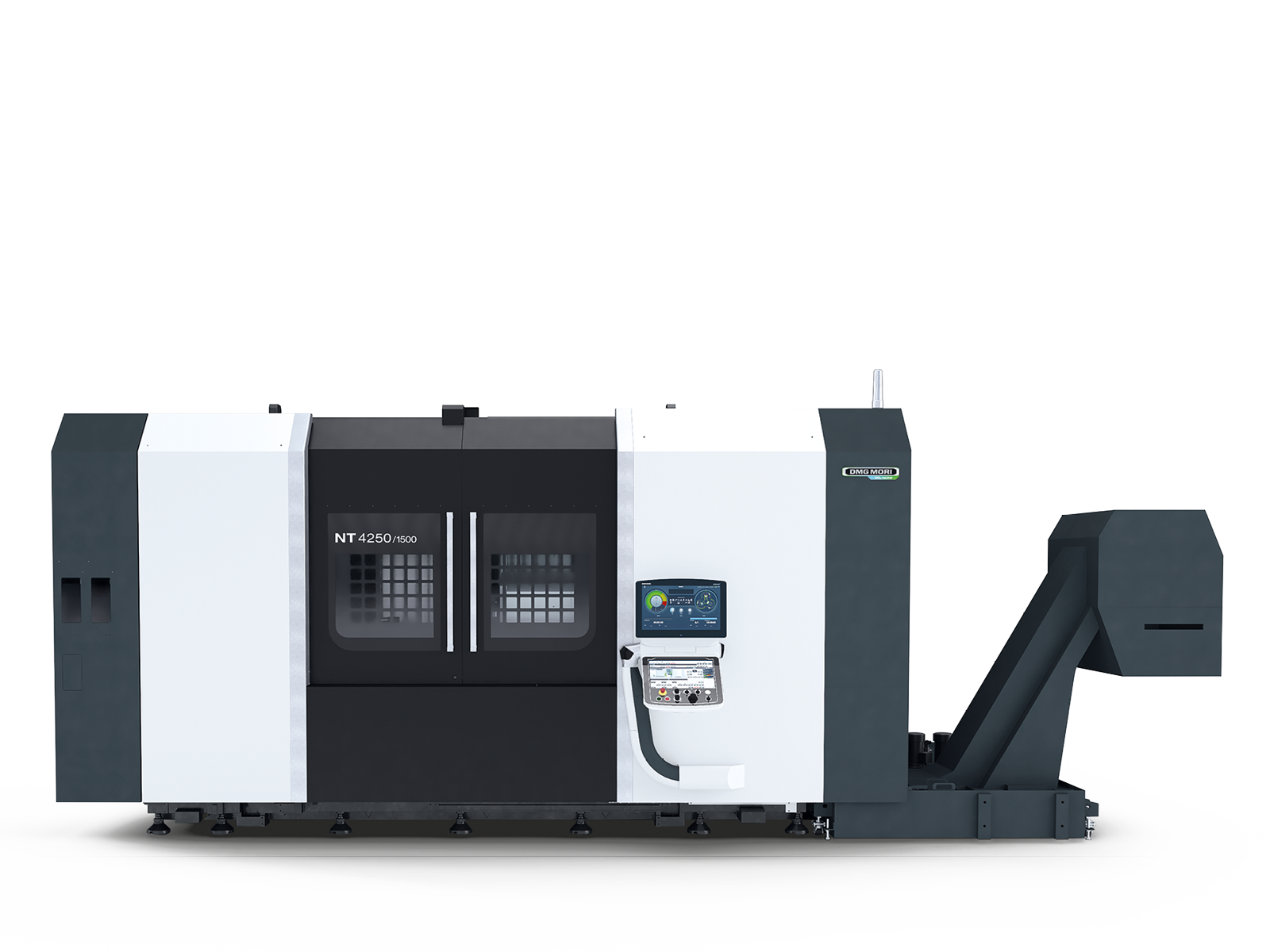

Mill & Turn (FD)

Turning on 5-axis milling machines

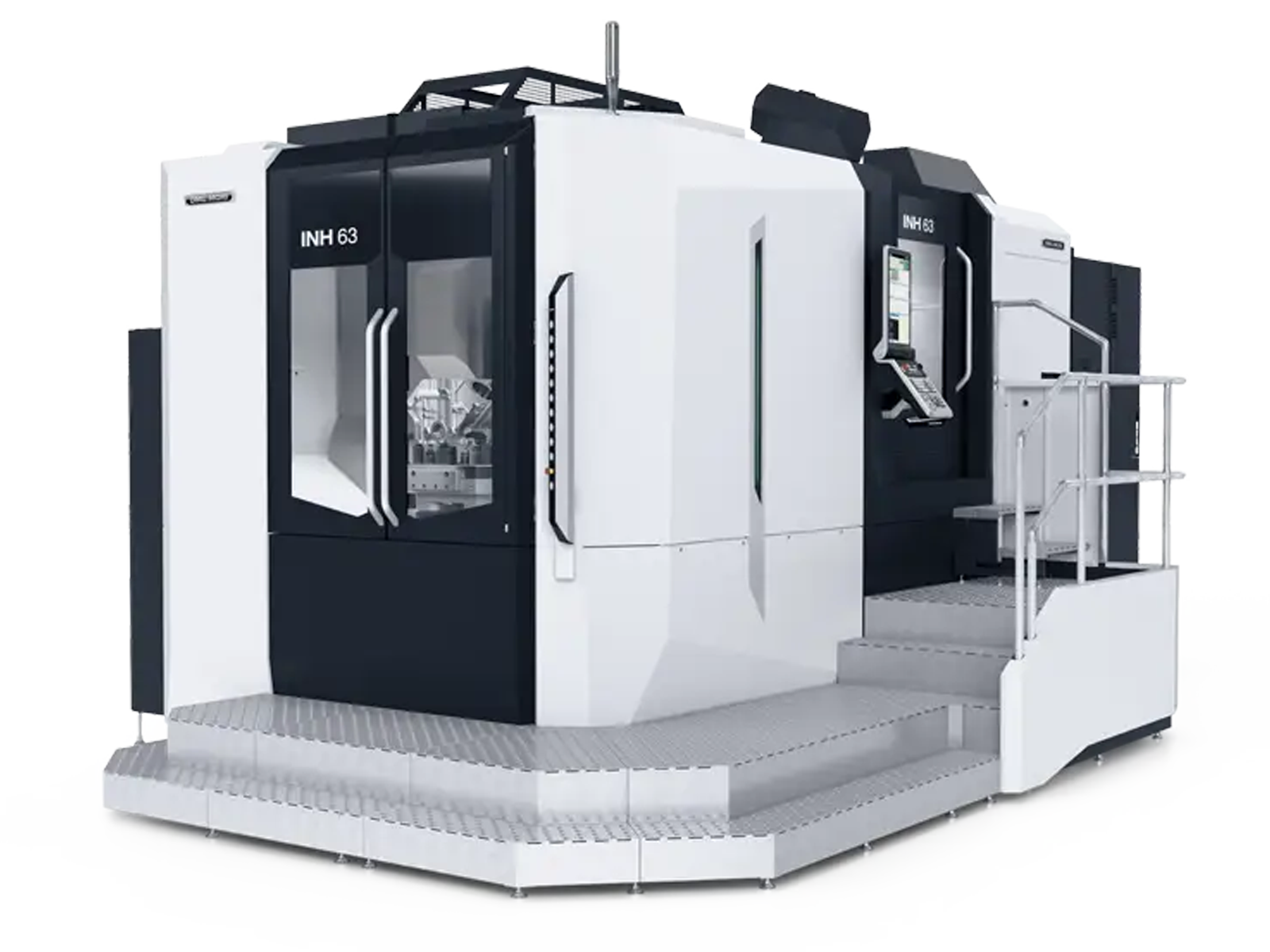

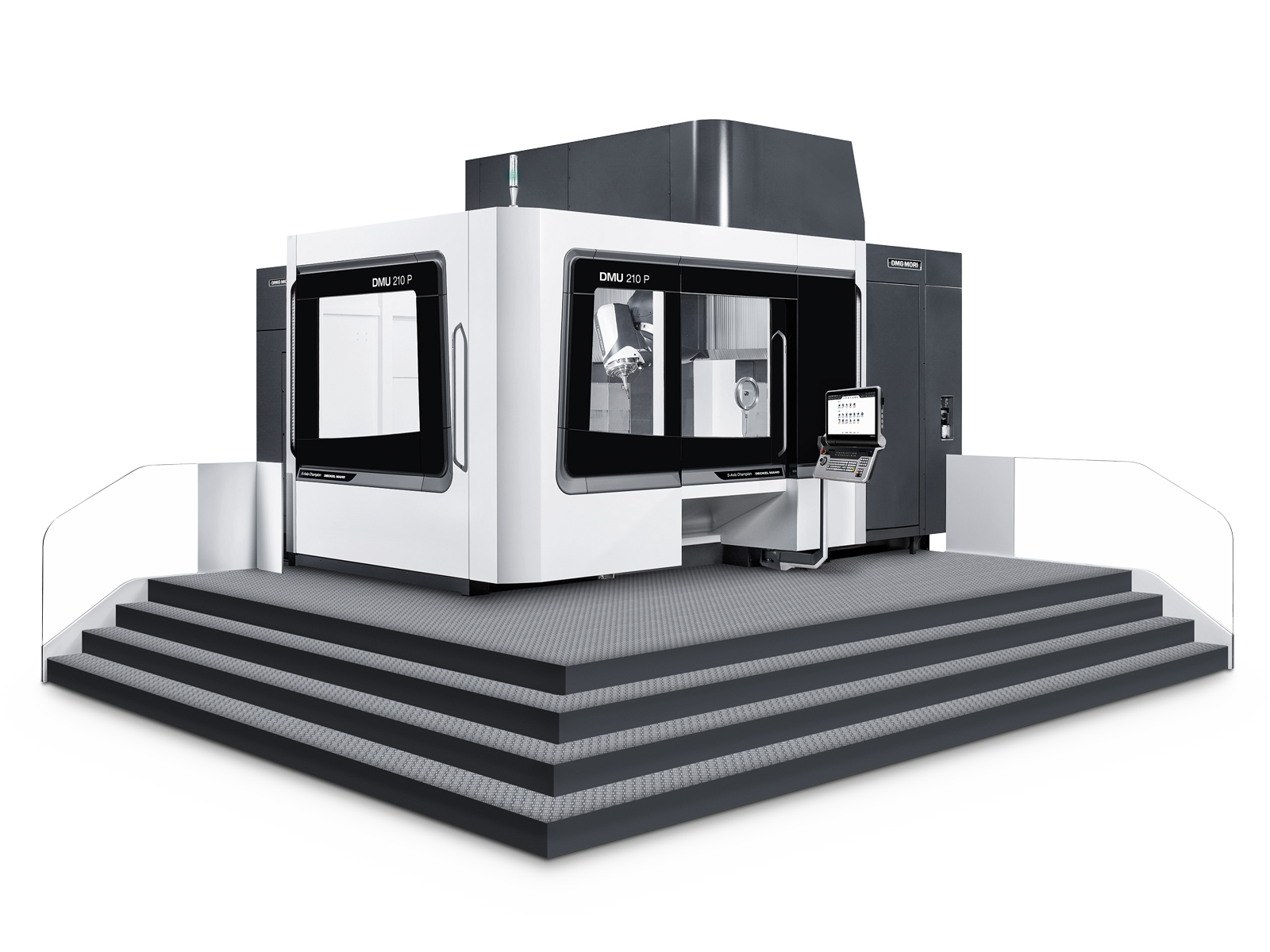

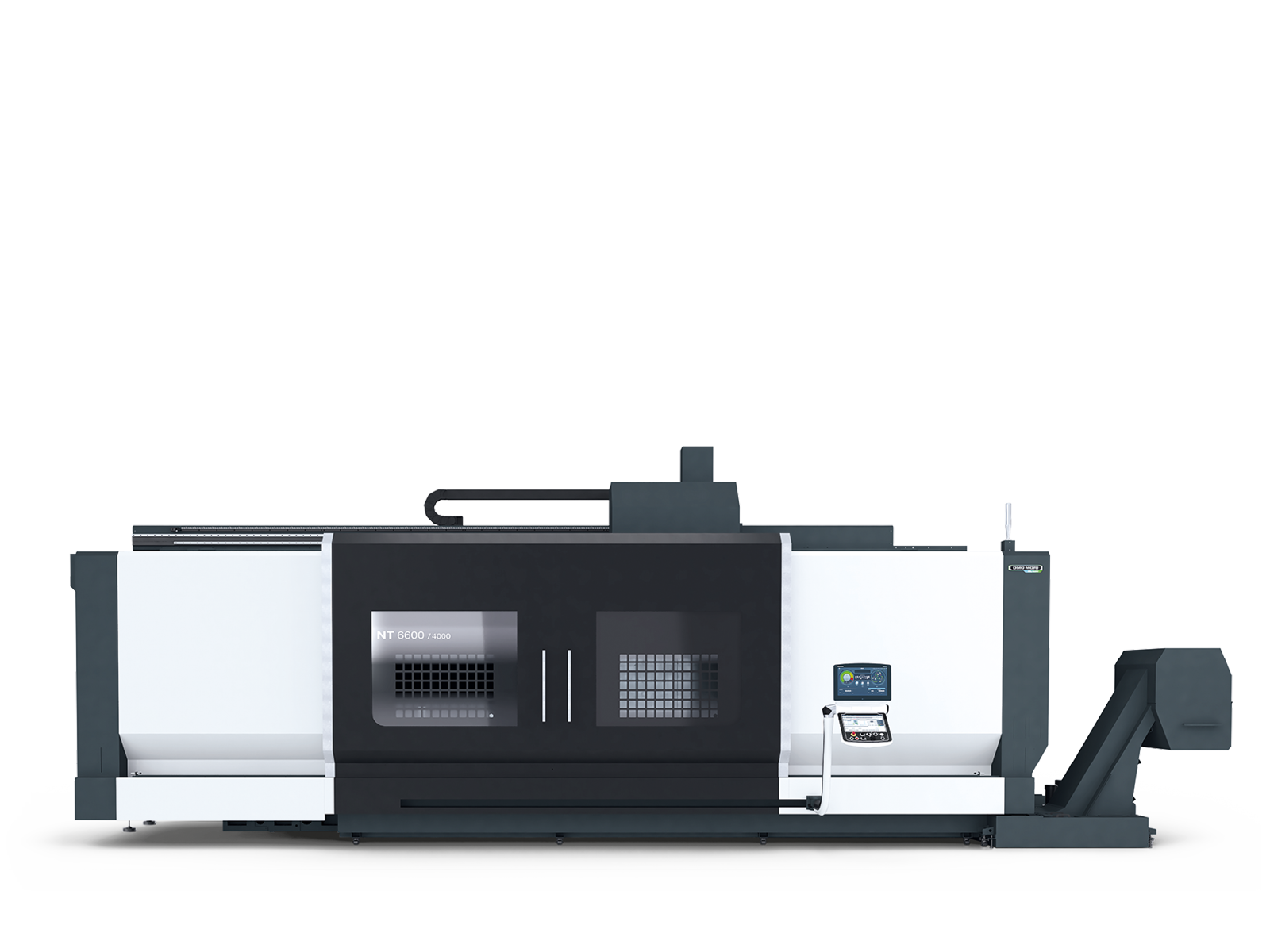

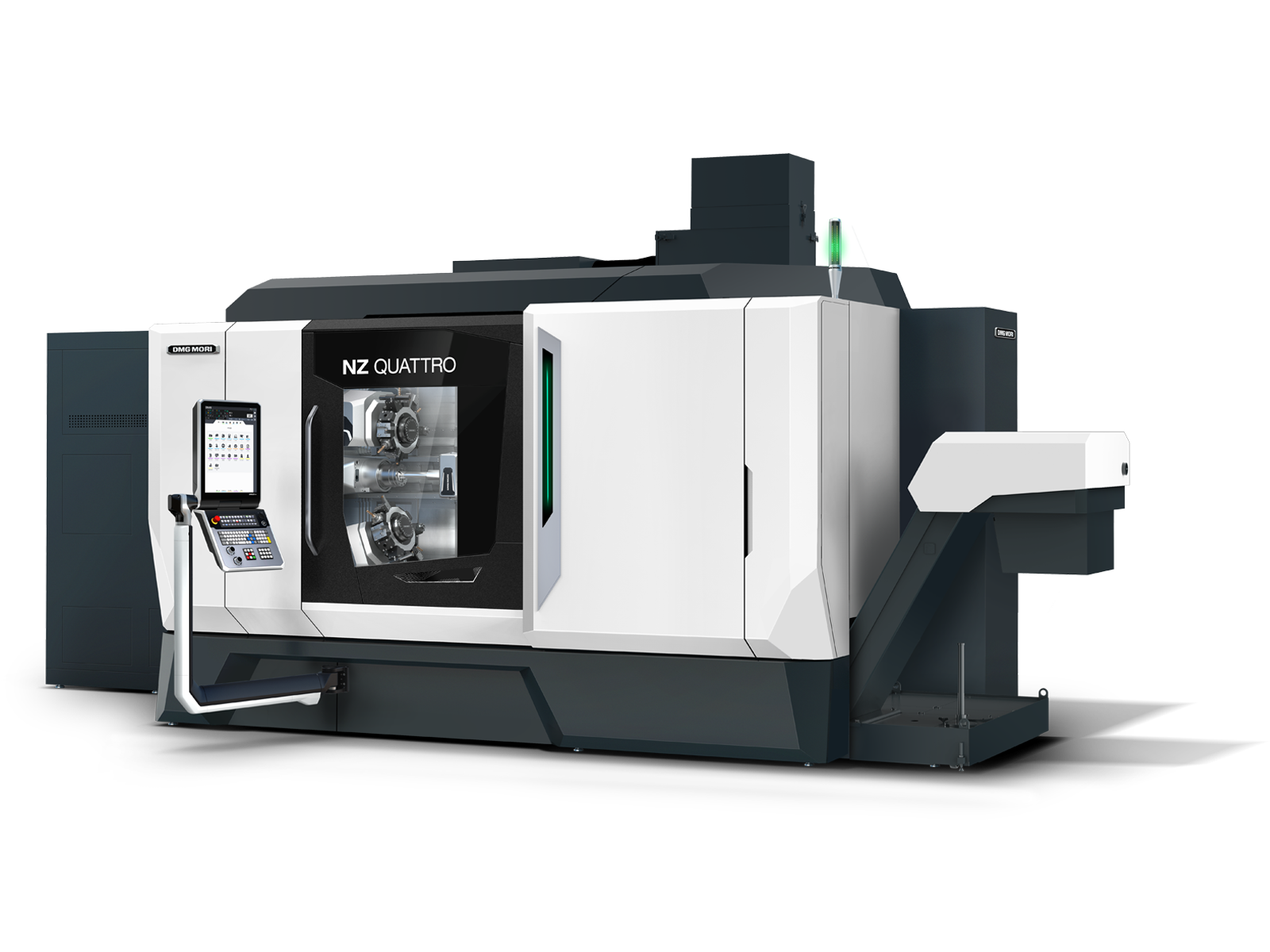

Turn & Mill

6-sided complete machining by turning and milling

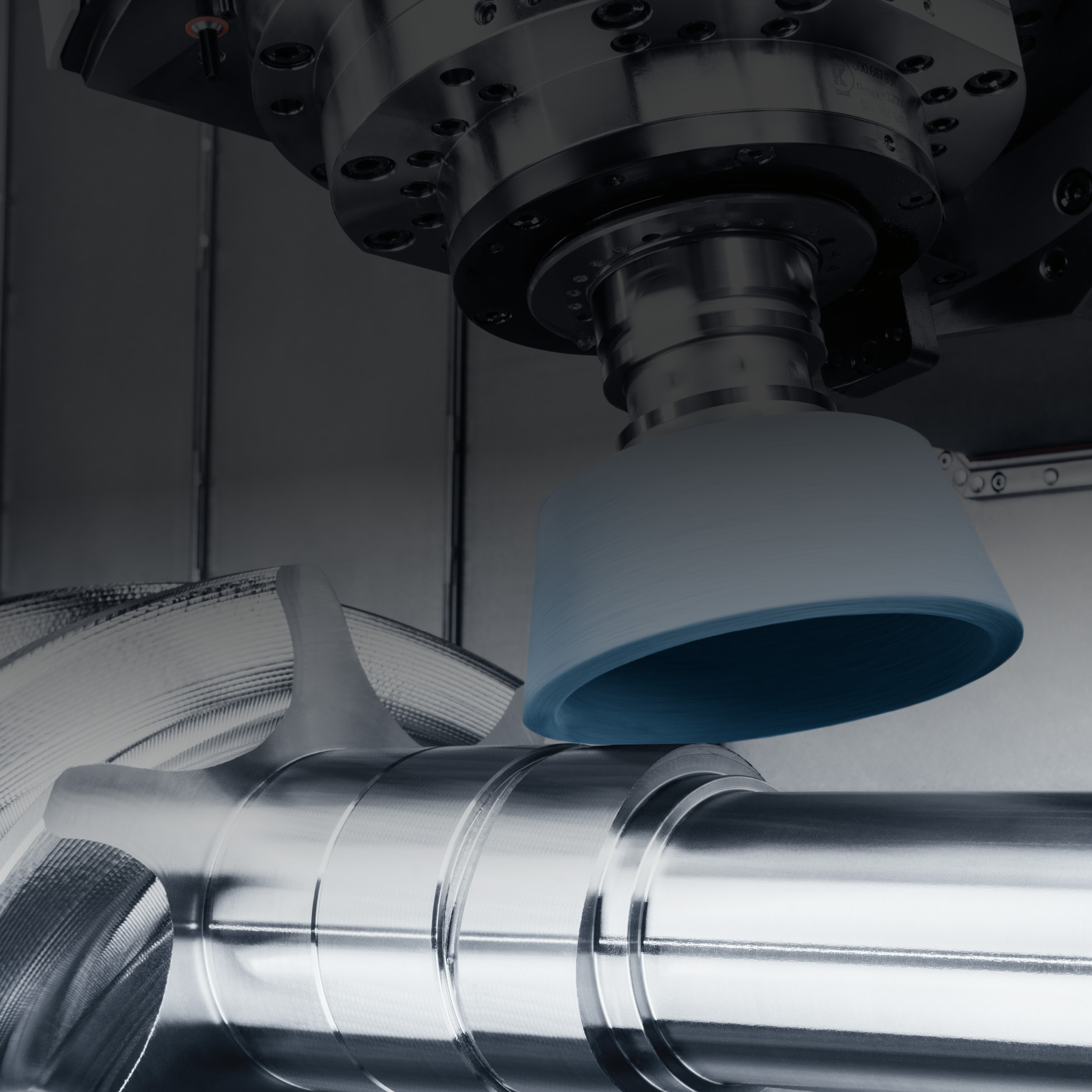

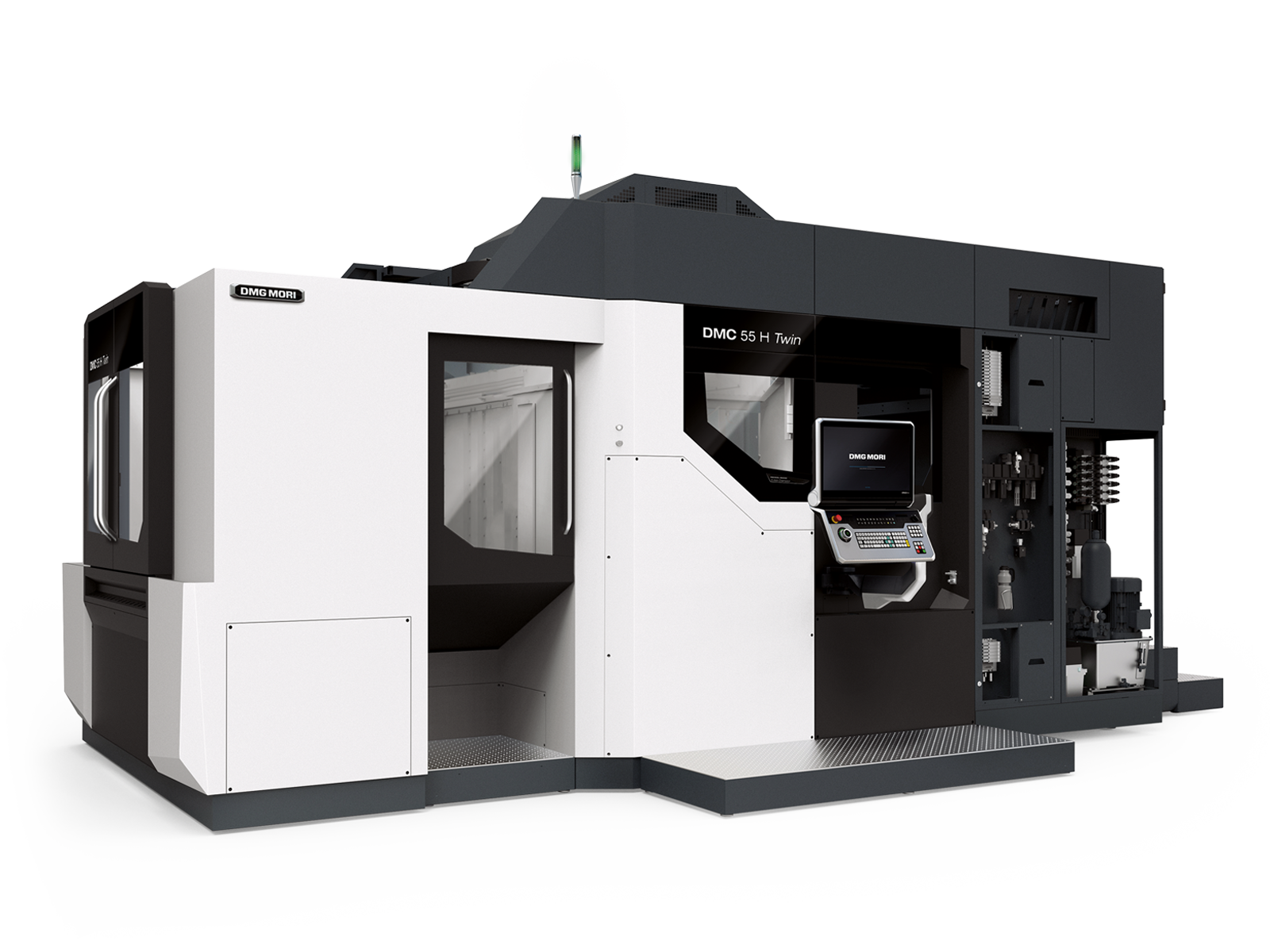

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

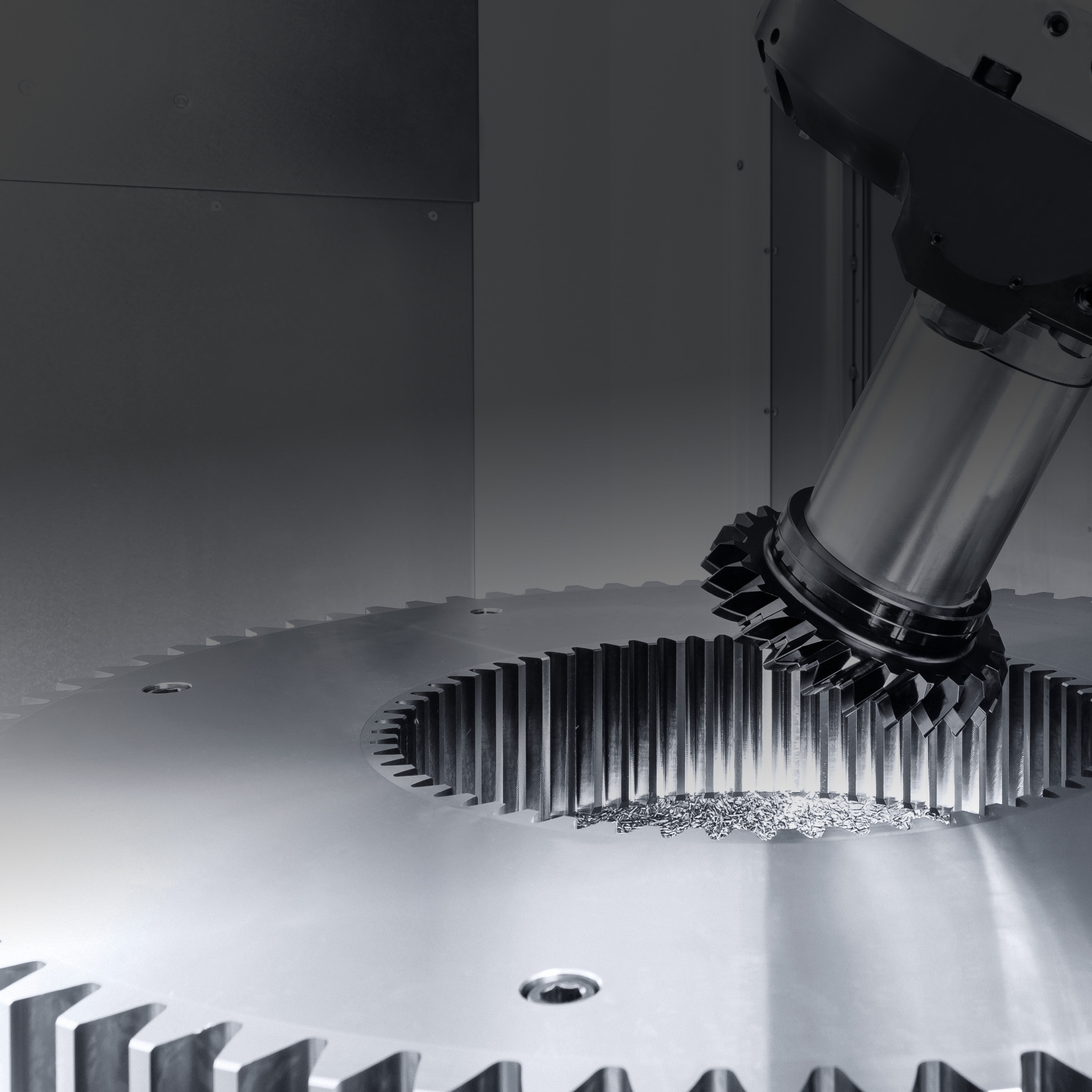

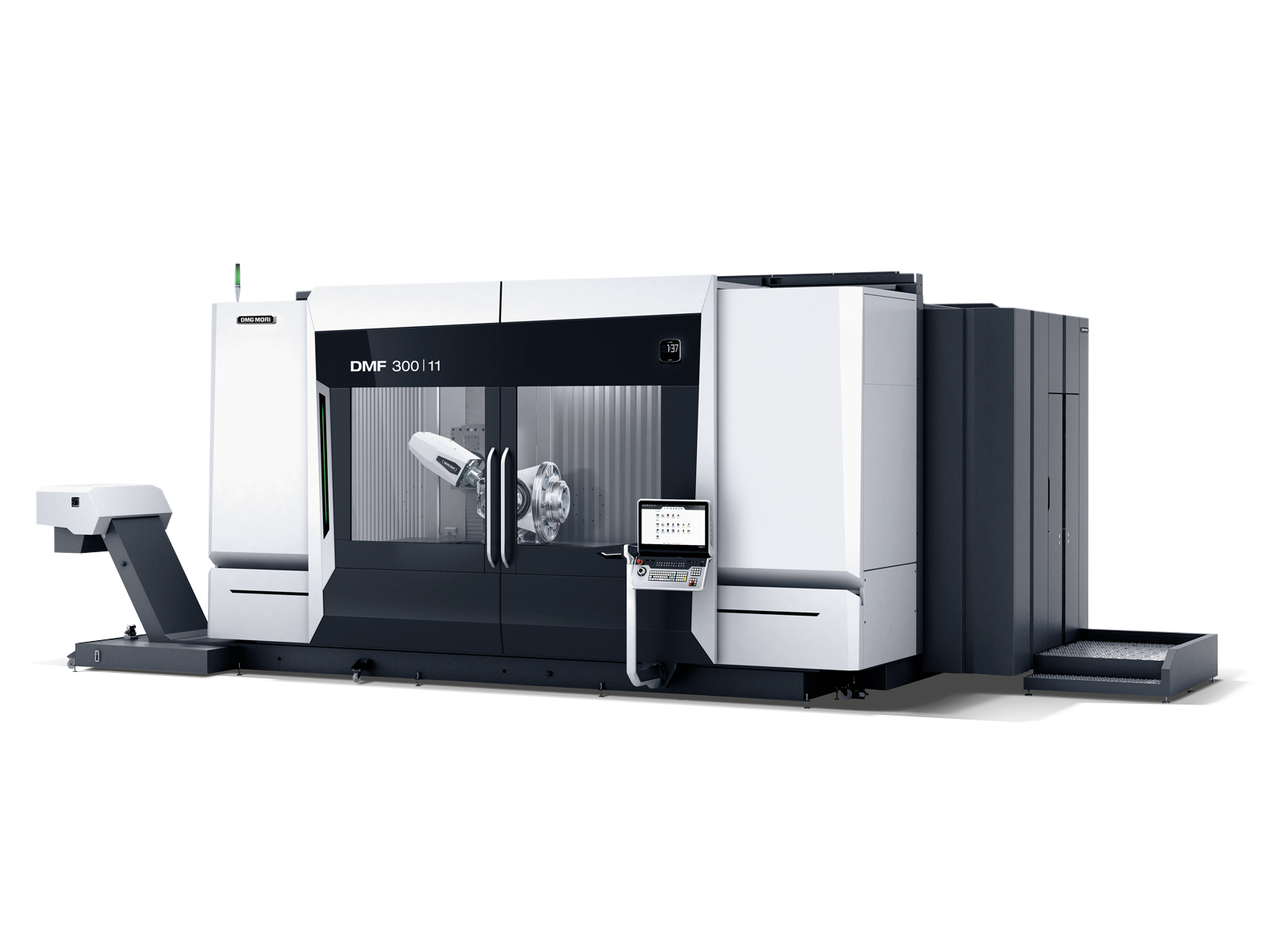

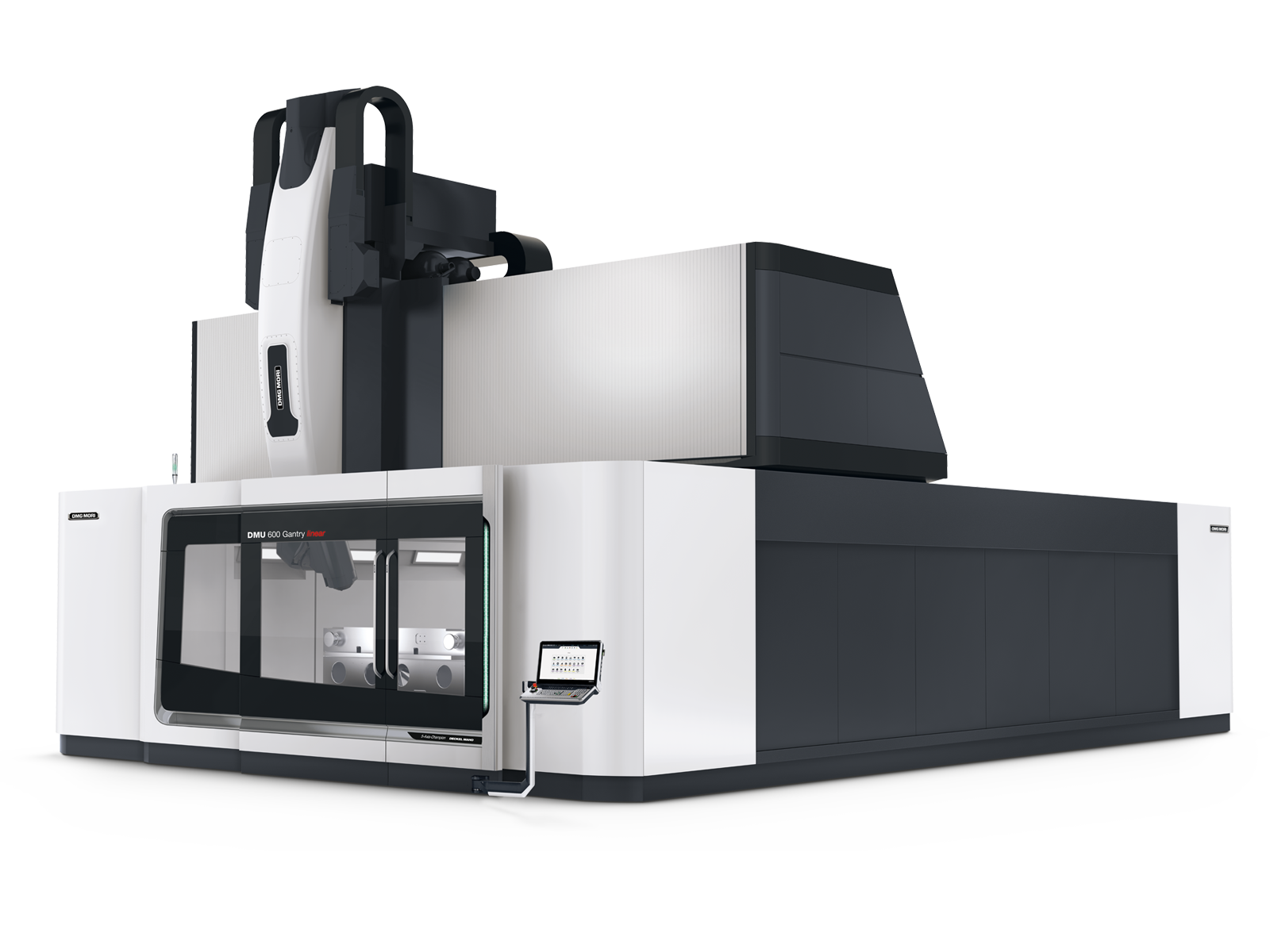

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

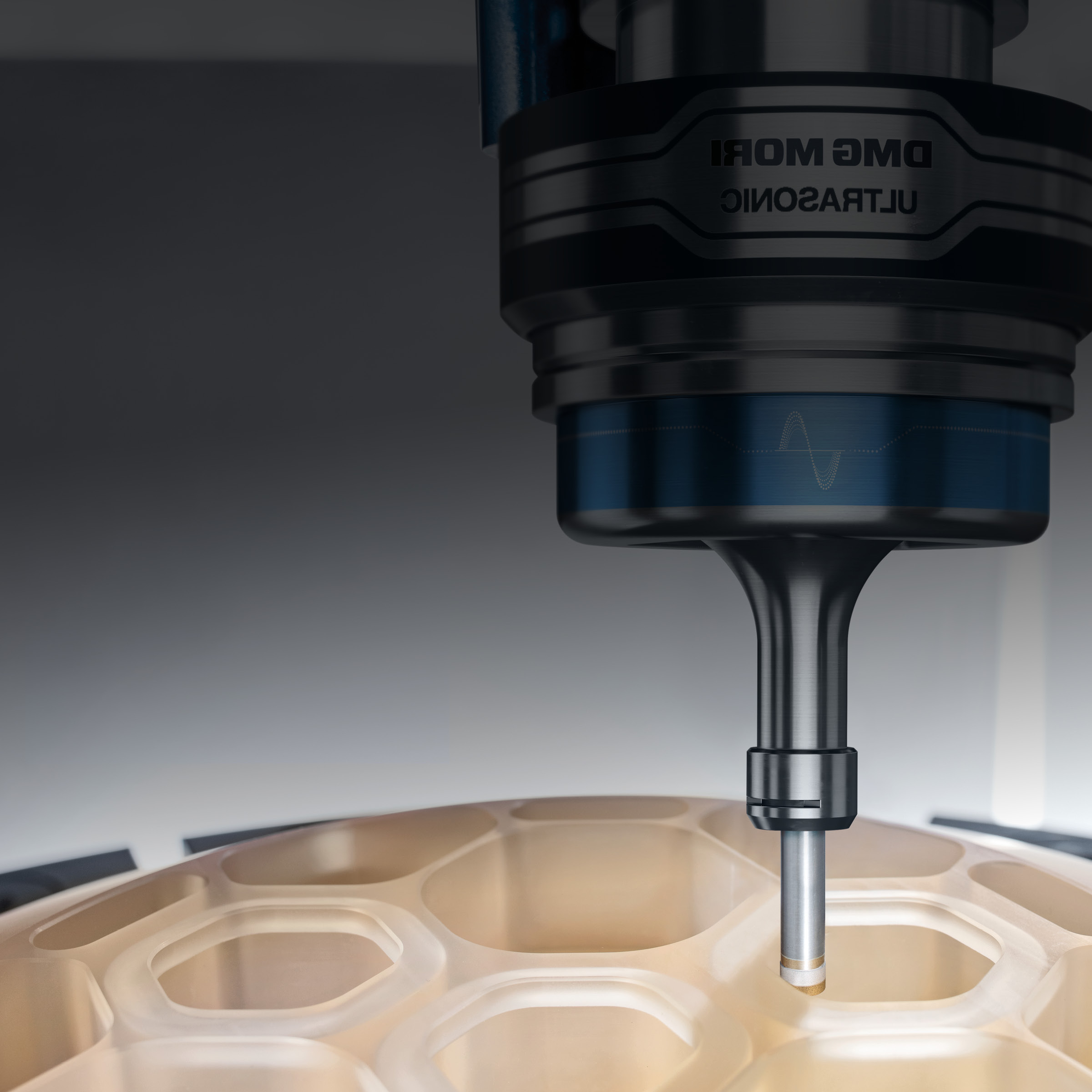

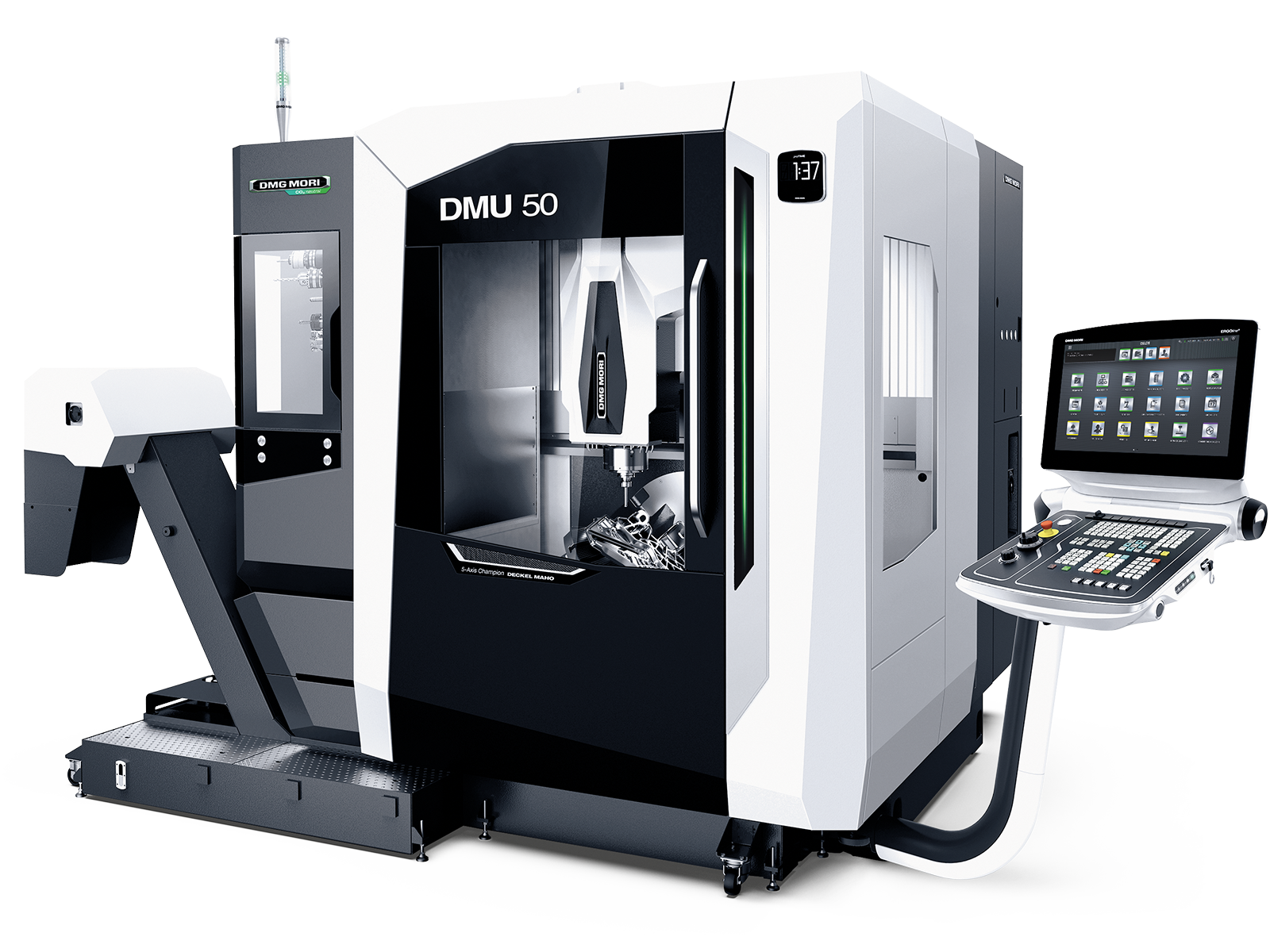

ULTRASONIC

Reduced process forces for very high productivity

LASERTEC

Contact-free 5-axis laser machining

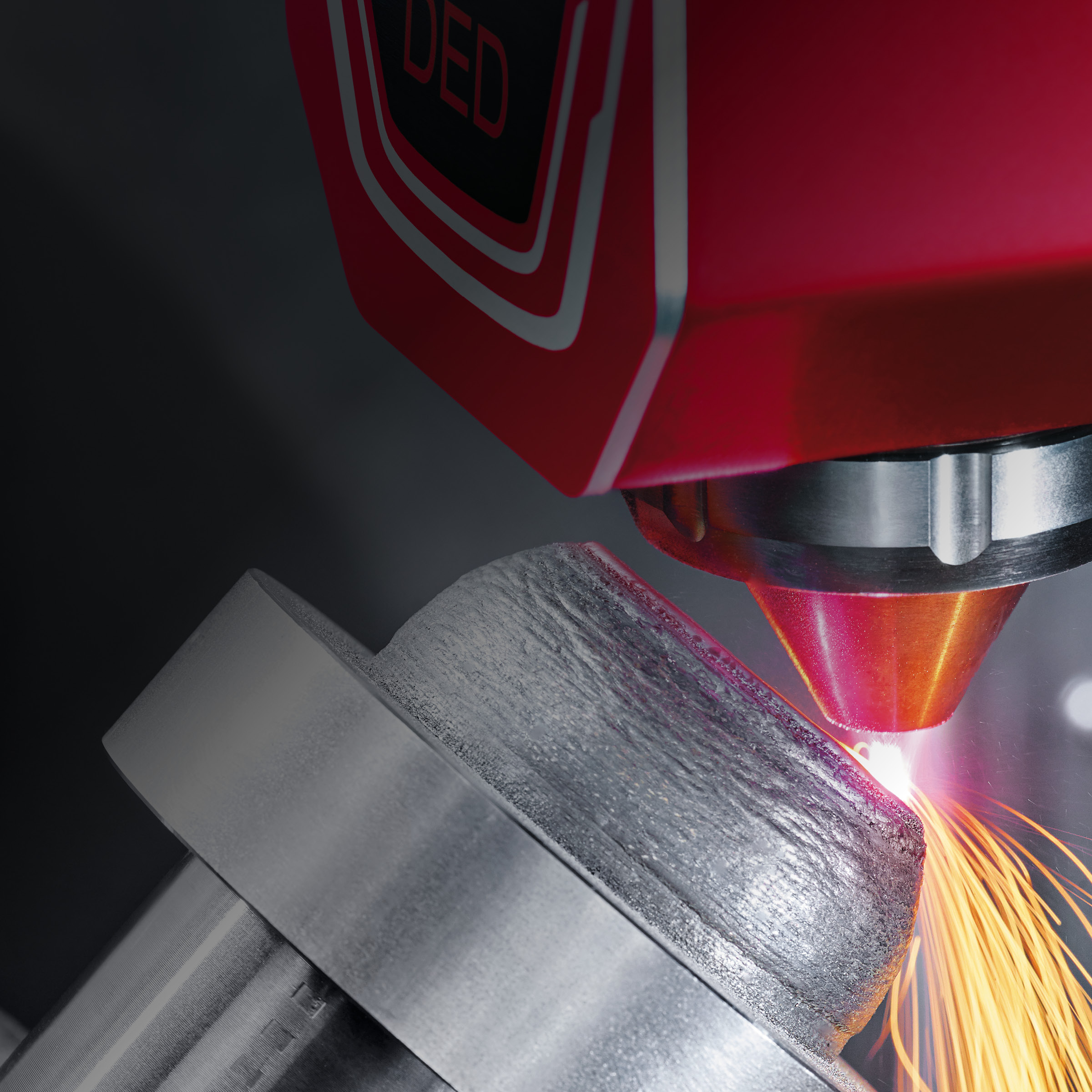

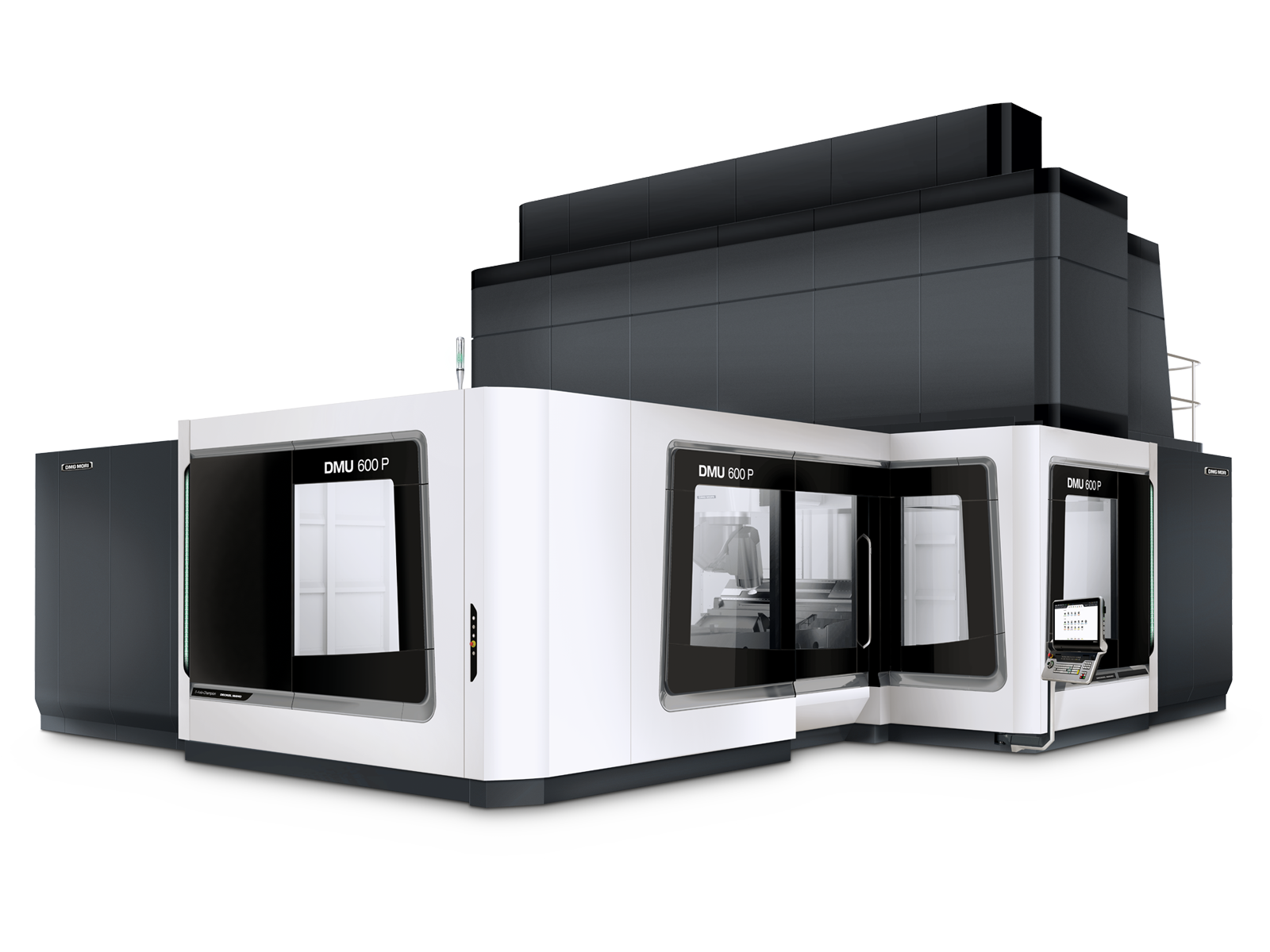

Additive Manufacturing DED hybrid

Milling, Turning and Additive Manufacturing on

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Or call us!

Or call us!