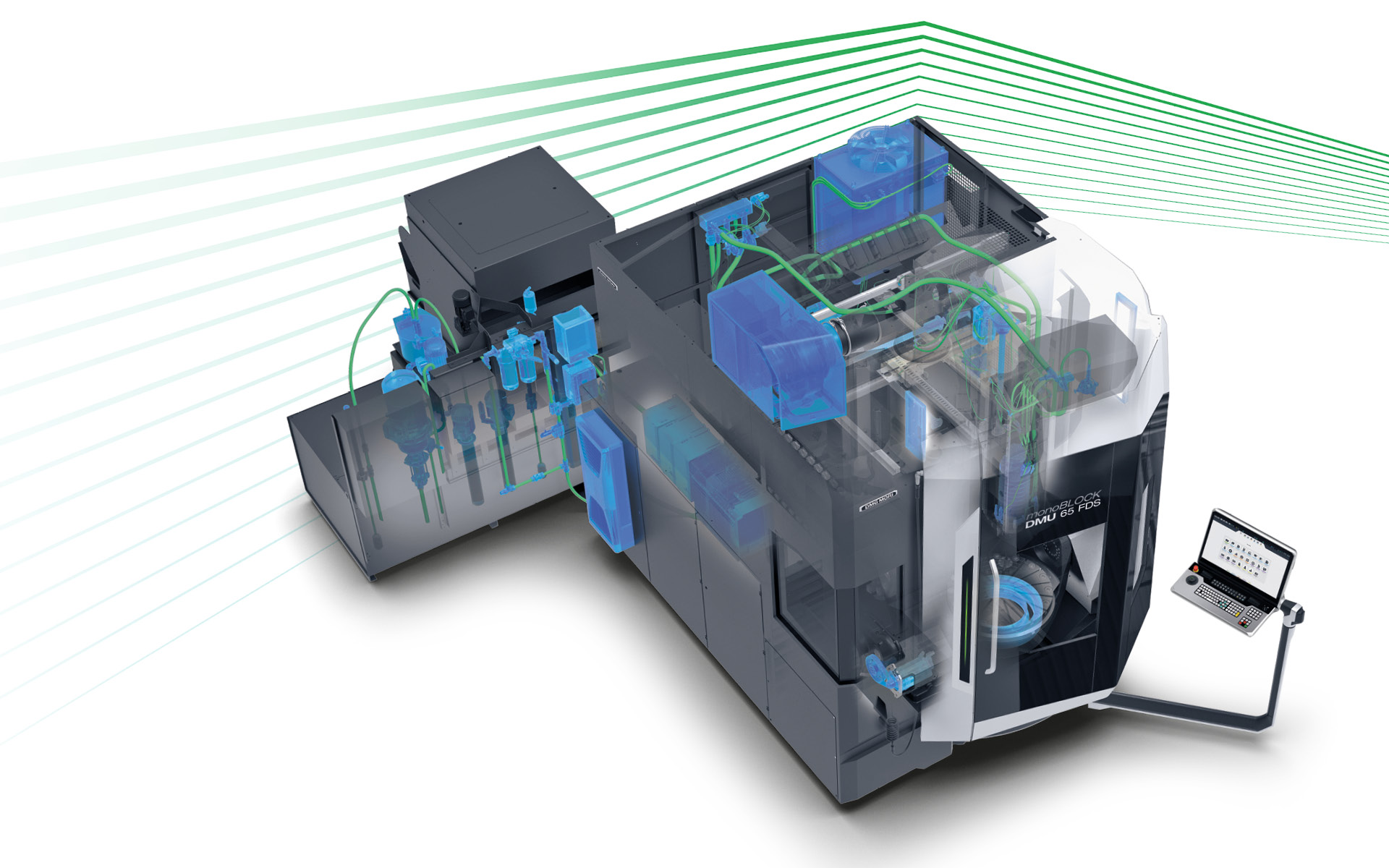

GX – Green Transformation and Sustainability

Integrated processes increase your productivity, reduce your energy consumption and maximize your profit

Increase sustainability

DMG MORI GREENMODE

13 GREENMODE MEASURES

- Brake Energy Recovery

- LED-Lights

- Highly Efficient Chillers

- Advanced Auto Shutdown

- Adaptive Feed Control

- Advanced Energy Monitoring

- Air Leakage Monitoring

- Frequency-Controlled Pumps

- zero-sludgeCOOLANT

- Adaptive Coolant Flow

- zeroFOG Mist Collector

- AI Chip Removal / Advanced Chip Removal

- Business Benefit Optimizer (BBO)

Or call us!

Or call us!