DMG MORI

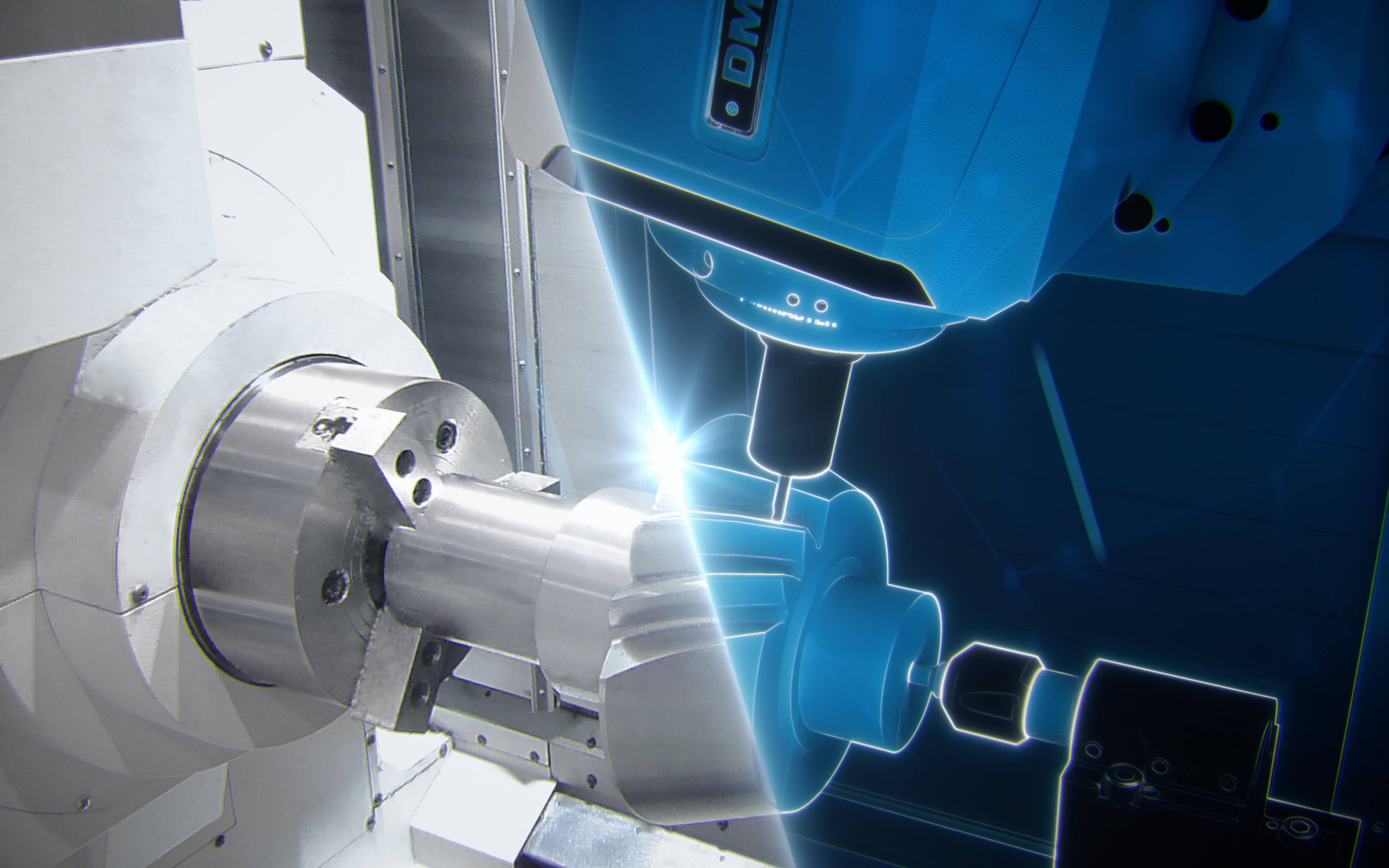

DIGITAL TWIN

Valued frontier worker between the worlds

Highlights

- 40 % faster production ramp-up

Carry out employee training and non-productive activities digitally - Up to 80 % faster start of production

Less testing and development on the machine - 100 % collision-free run-in

Complete digital testing and optimization

Or call us!

Or call us!