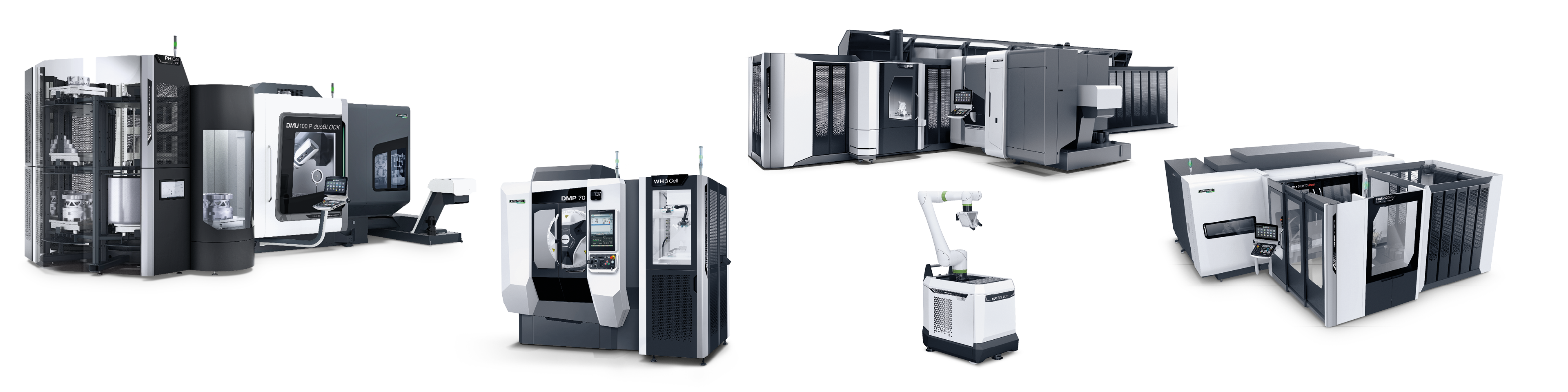

Machining Transformation (MX)

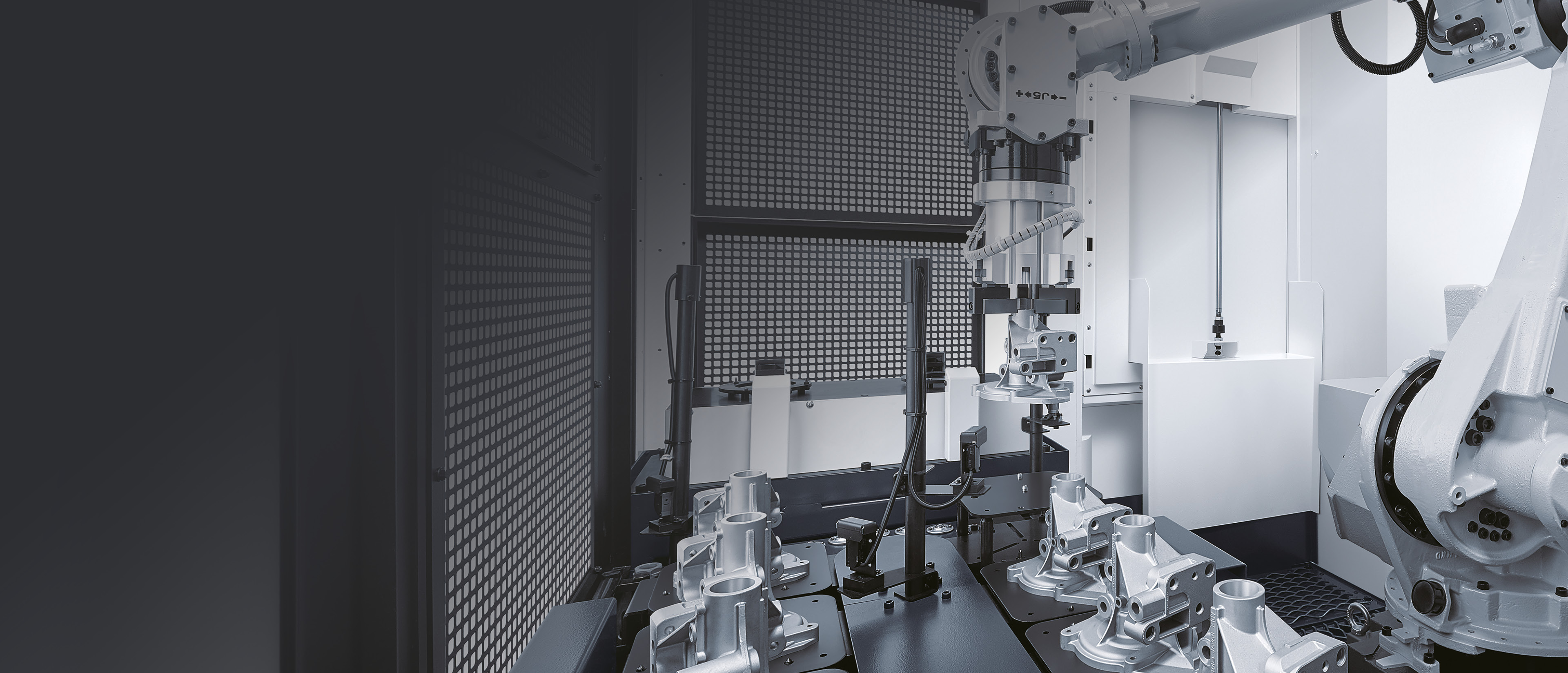

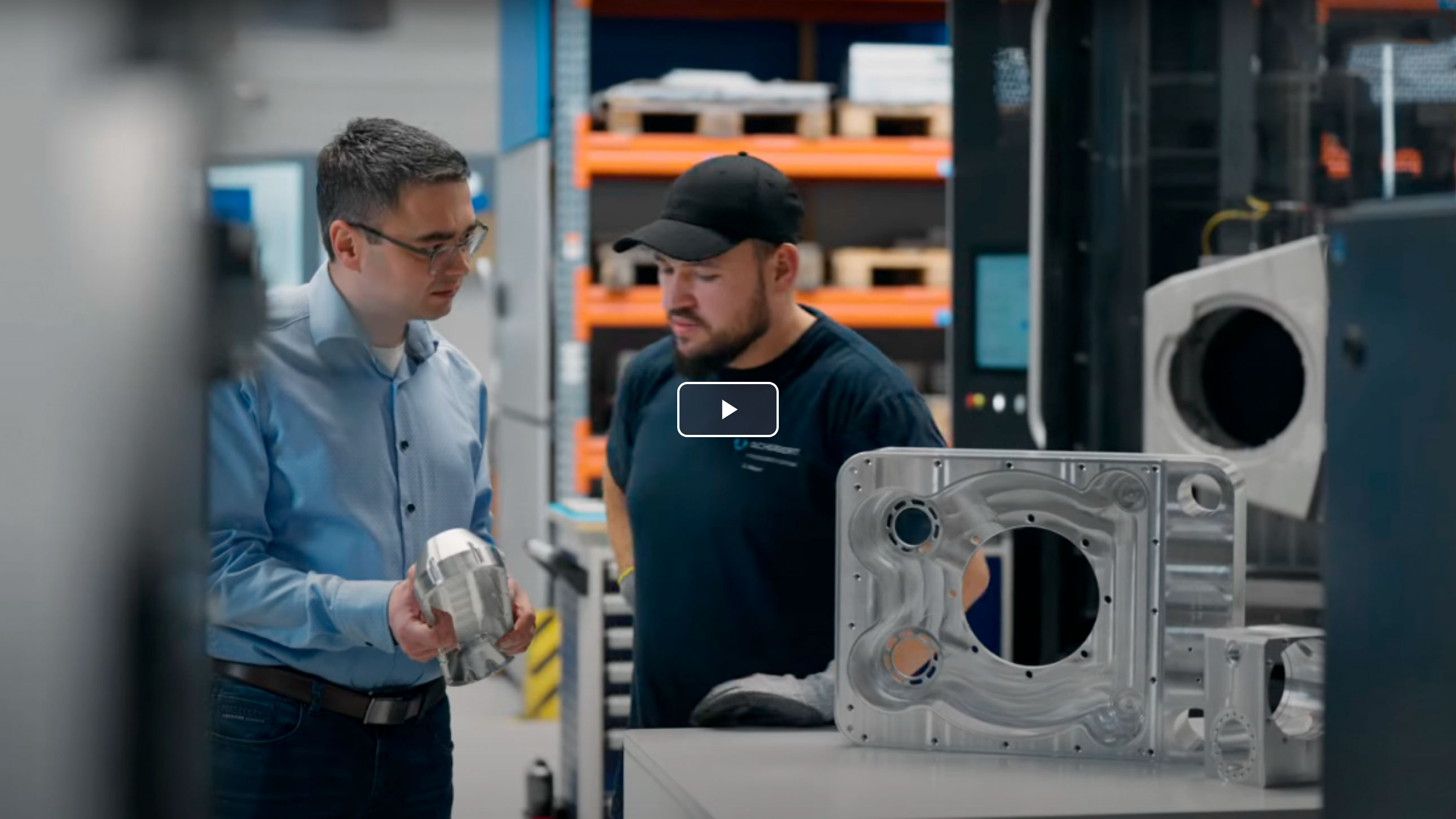

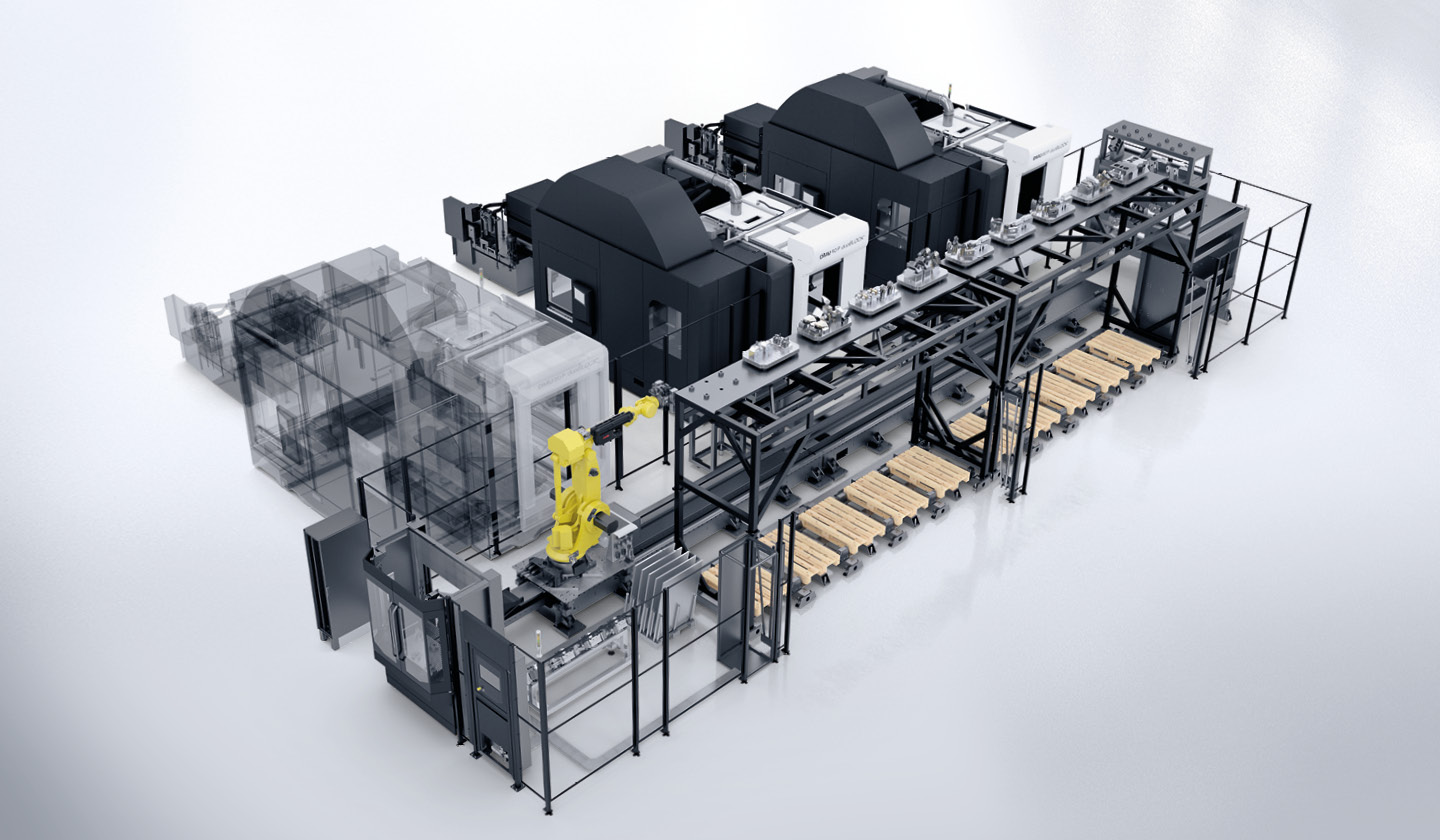

AUTOMATION

For additional low-man

or manless night and / or weekend shifts

Benefits

Easy to use

Proven technology

Night shifts & weekends

Become more competitive

Flexibility

Sustainability

Retrofit automations for your existing machines*

*Possibility of retrofit depends on machine preparation, e.g. automation interface

Always the right solution

Learn more in our Webinars

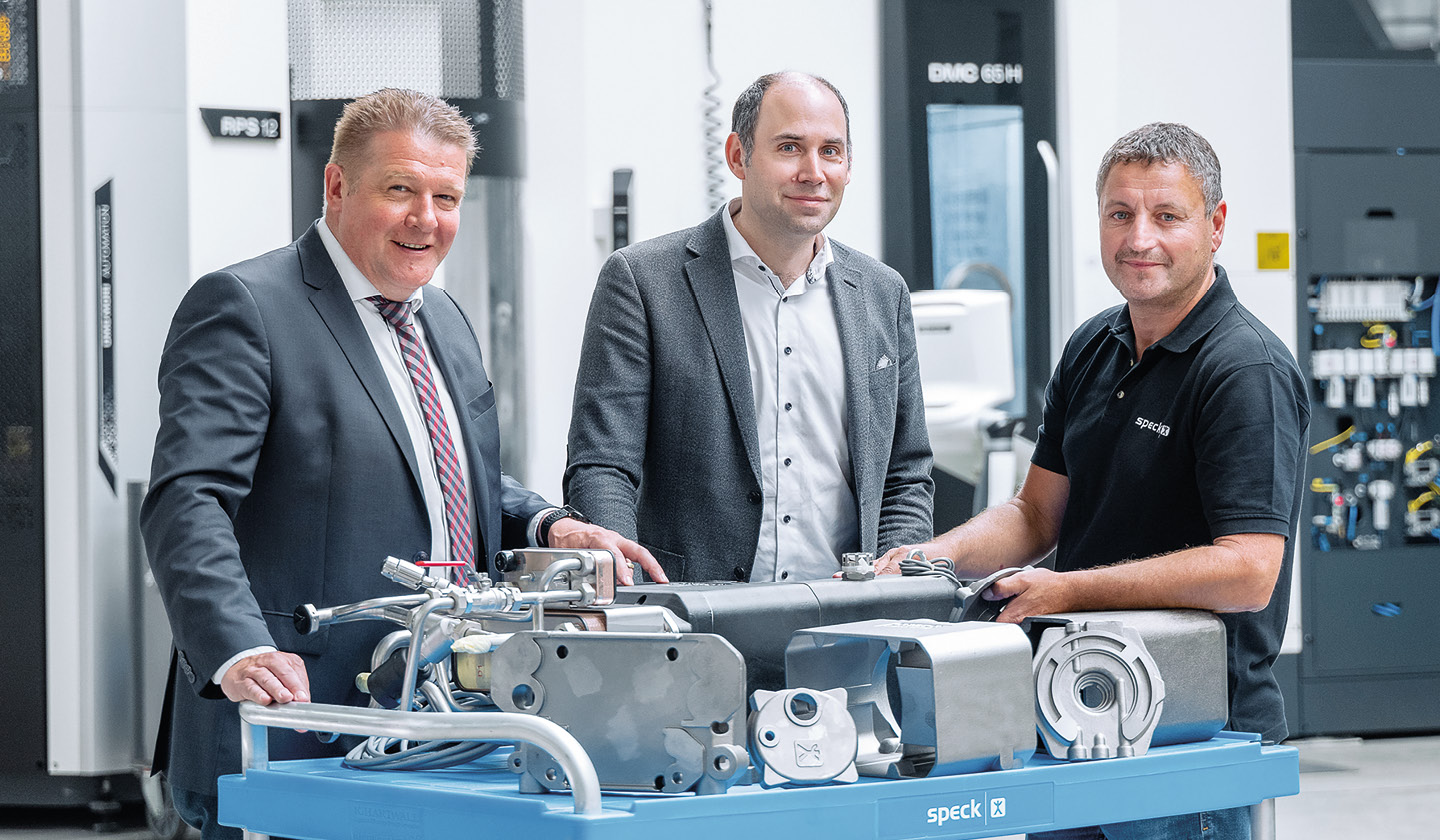

We support you!

- Professional site management

- One contact for everything

- CE certification

Want to know more?

Just contact us to discuss what this could do for your business …

Torsten Zwerenz,

Head of Global Service Systems

DMG MORI Global Service GmbH

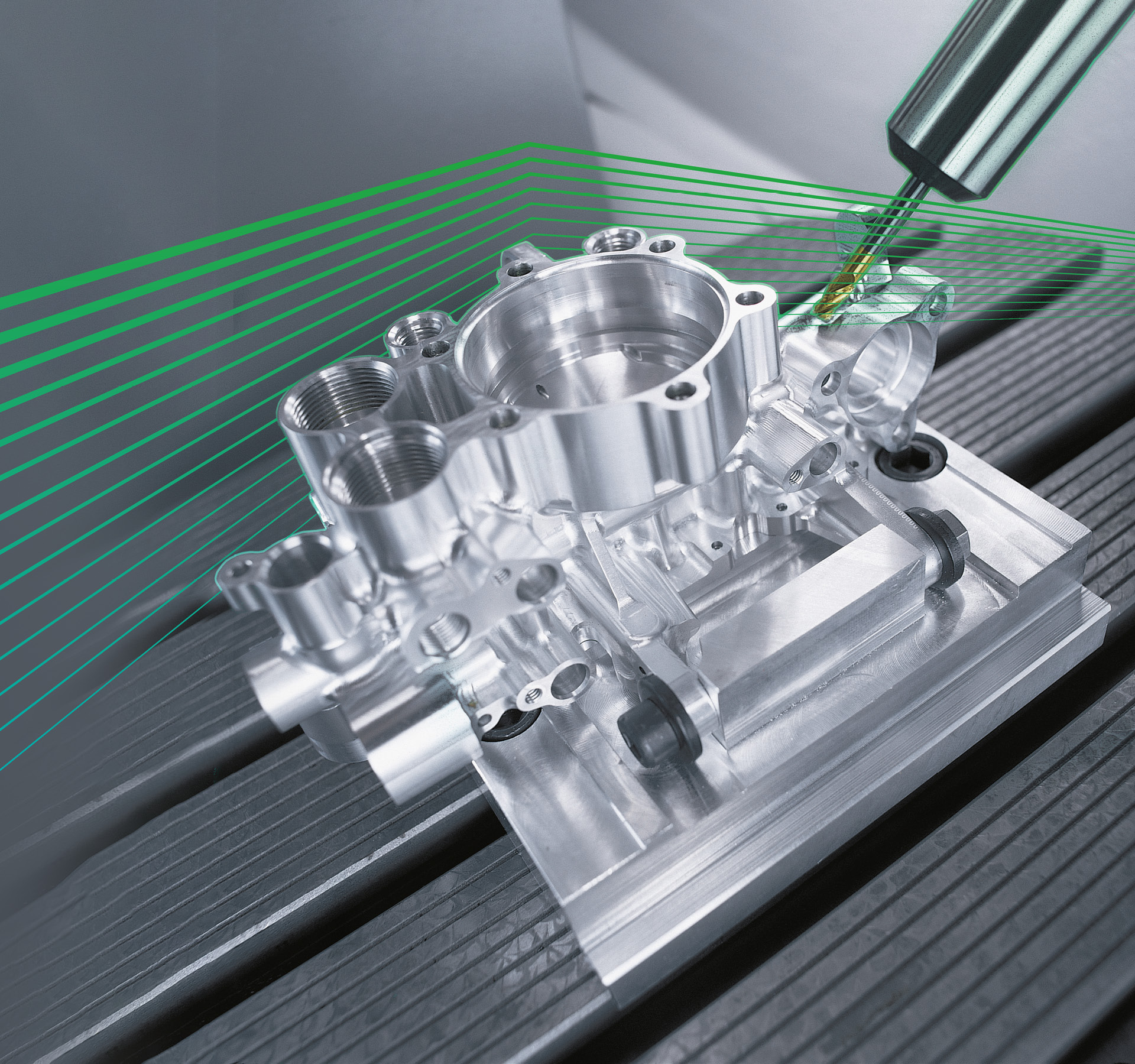

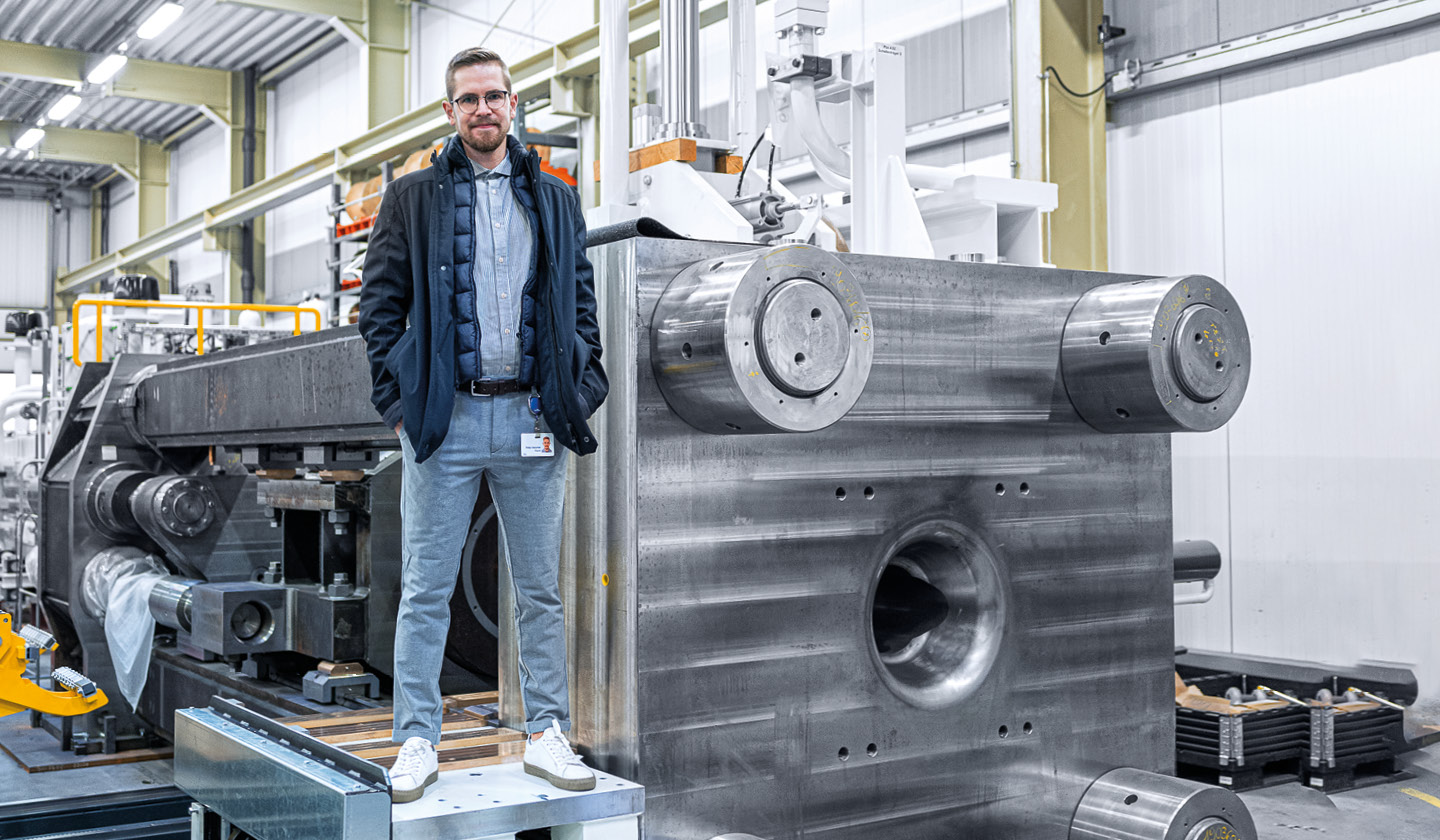

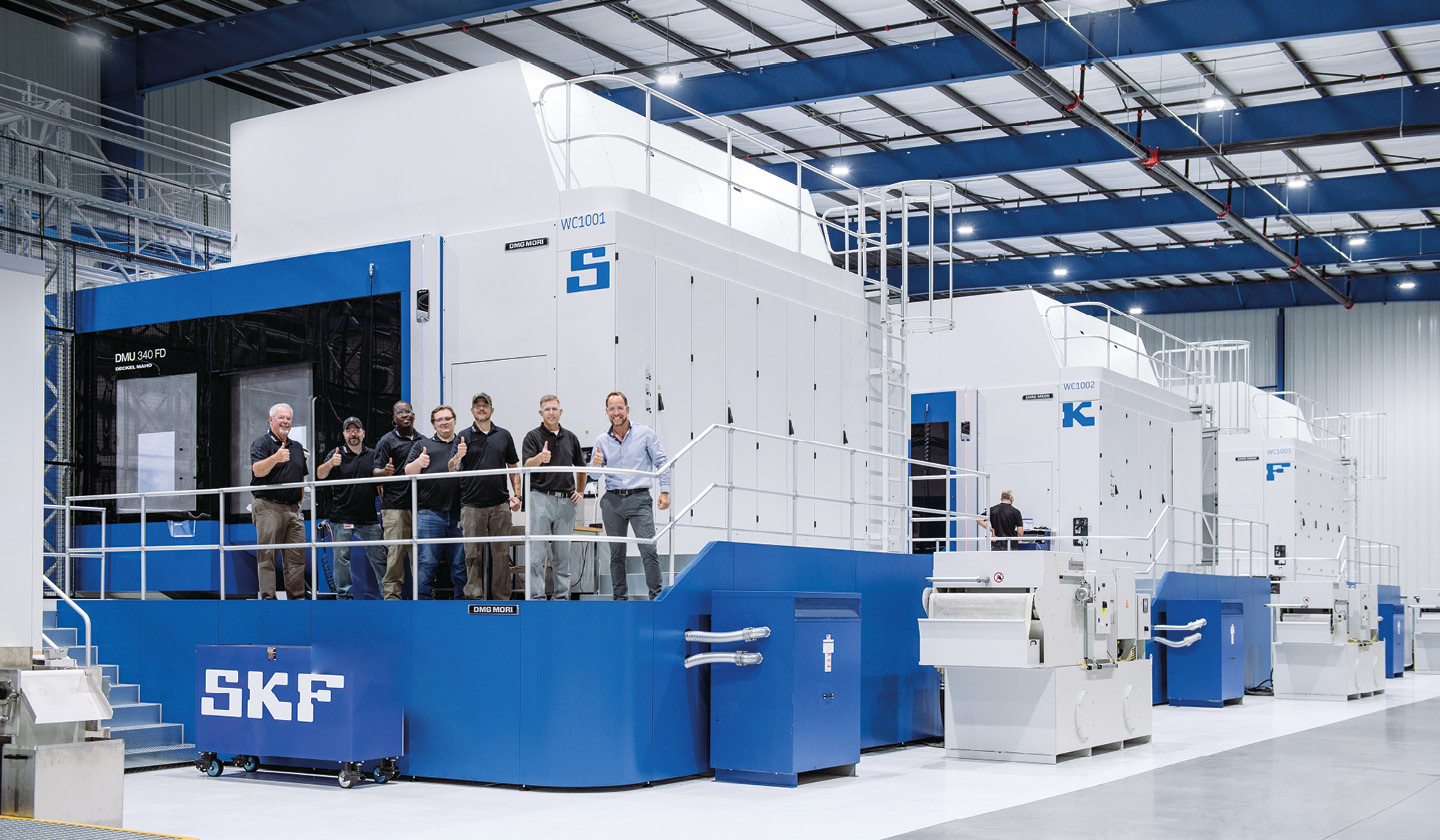

Process Integration

Higher utilization of a complete machining center, instead of partial utilization of several simple machines.

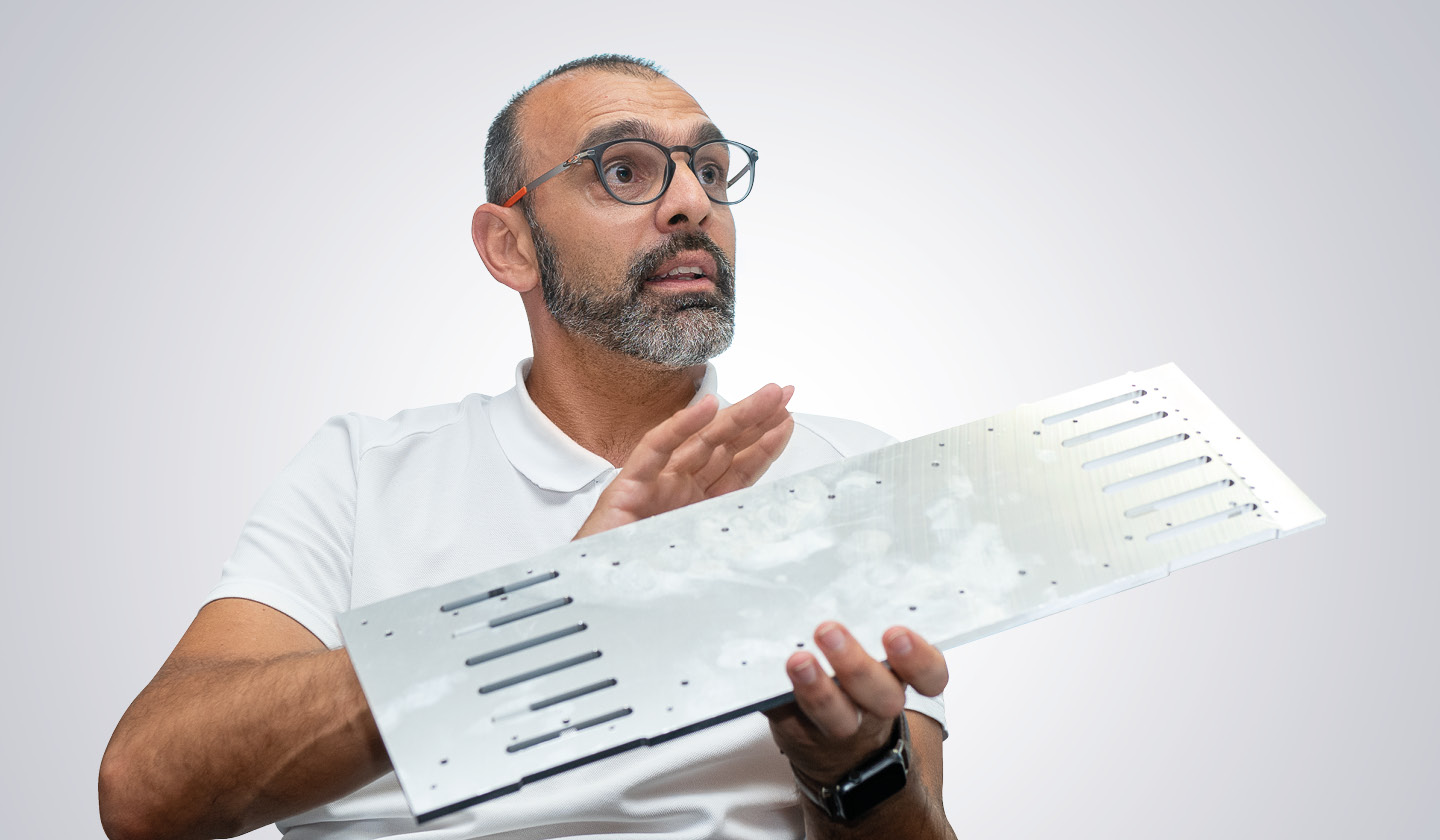

Automation

For additional low-man or manless night and / or weekend shifts.

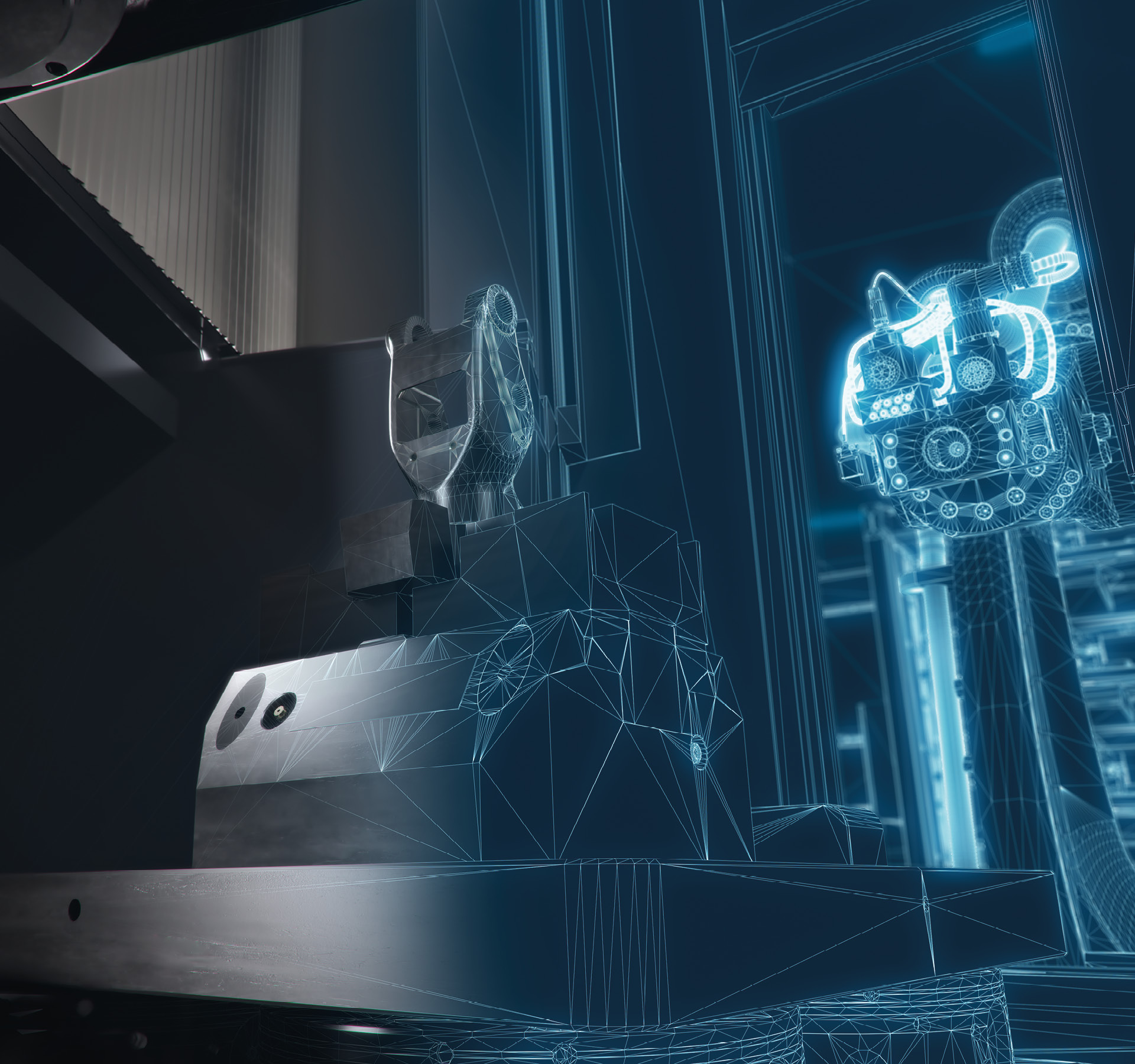

Digital Transformation (DX)

From CAD-CAM solutions and post-processors to simulation using Digital Twin and DMG MORI technology cycles for up to 60 % shorter programming time

Green Transformation (GX)

Integrated processes increase your productivity, reduce your energy consumption and maximize your profit.

Or call us!

Or call us!