Machining Transformation (MX)

DX

Digital Transformation

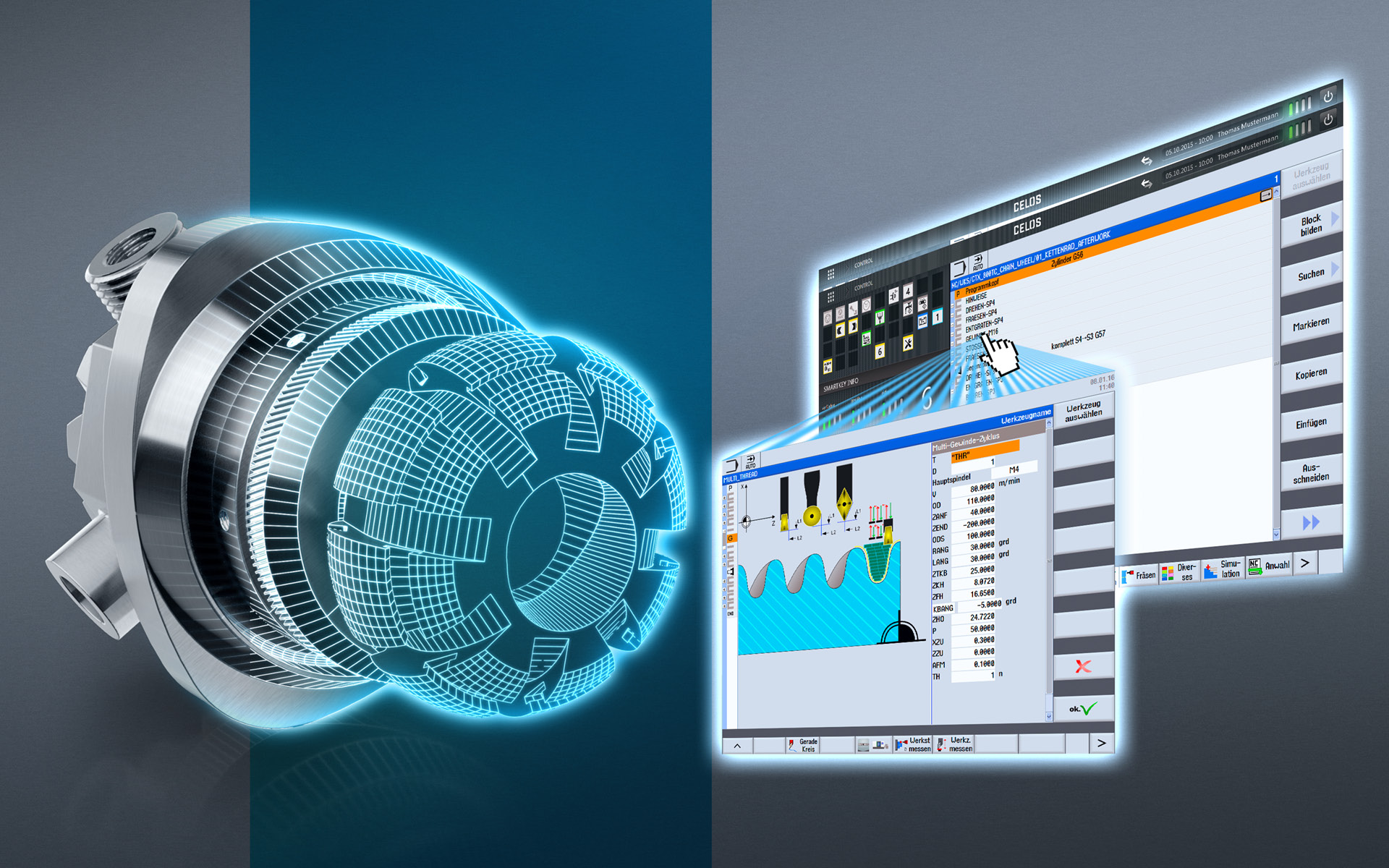

From CAD-CAM solutions and post-processors to simulation using Digital Twin

and DMG MORI technology cycles for up to 60 % shorter programming time

DMG MORI Connecitivity

- MACHINES

DMG MORI & 3rd party machines - DATA ACCESS

Access on premise or via the cloud using all common protocols - CYBERSECURITY

Leading security and auditing standards

1. WHY CONNECTIVITY?

- Without data you don´t know where to improve

- Empower your digital solutions like status monitoring system or planning application with machine data and explore the potential to increase your productivity

- To protect your investment and business through transparency

2. WHAT YOU GET?

- Standard machine data interface – ready for DMG MORI applications or your digitization project

- 17 machine signals for DMG MORI machines from 2013 (can be extended as an option) and minimal dataset for DMG MORI machines before 2013, 3rd party and periphery devices

- Data access on premise or via cloud

3. YOUR PATH TO CONNECTIVITY

- Request connectivity at your DMG MORI Sales Representive

- DMG MORI checks your installed base (DMG MORI and third party machines)

- If needed – Installation of IoTconnector or IoTconnector flex

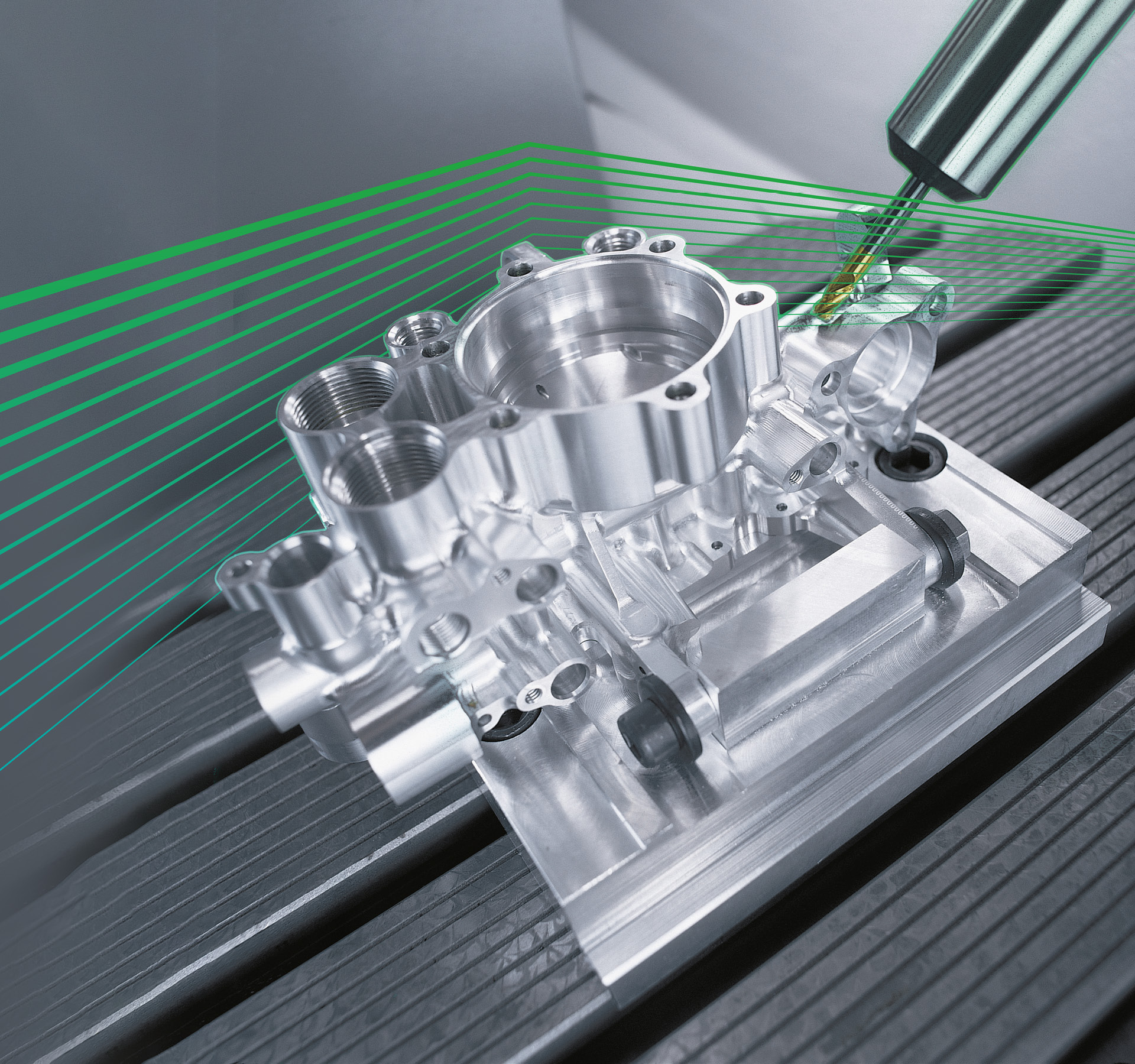

DMG MORI Technology Cycles

The exclusive Technology Cycles by DMG MORI are real assistants in the field of workshop-oriented programming for increasing productivity and security, as well as increasing machine capability.

- Clear programme structure

- Up to 60% faster programming

- Errors are minimised thanks to programming guided by dialogues

- New technologies (gearSKIVING, grinding)

- Technology expertise stored in the program

MACHINING CYCLES

- Integrates new machining technologies e. g. gearSKIVING

- Expands machine capability – e. g. grinding

- Simplifies complicated programming tasks – e. g. Multi threading 2.0

HANDLING CYCLES

- Simplifies machine operations e. g. – B-axis ramping

- Automates workflows – e. g. counter spindle live center

- Protects against operator errors with higher safety – e. g. turret steady rest

MEASURING CYCLES

- Increases machining accuracy – e. g. 3D quickSET

- Opens up new measuring possibilities for bulky component geometries – e. g. L-measuring probe package

- Increases transparency in QC processes – e. g. gearMILL with

in-process measurement

MONITORING CYCLES

- Increases machine safety – e. g. MPC – Machine Protection Control 2.0

- Increases process safety – e. g. Easy Tool Monitoring 2.0

- Adapts process parameters to eliminate vibrations – MVC – Machine Vibration Control

Learn more in our Webinars

CELOS DYNAMICpost

- Dedicated post-processor to generate NC programs that match DMG MORI machine

- DMG MORI machines’ specific functions are supported

- Application Tuning Cycle:

Large reduction in roughing machining time

CUTTING FORCE OPTIMIZATION

- Cutting force optimization function to optimally control machining conditions 1

- Controlled cutting force reduced machining time by 20 % and tool breakage 2

- Simulation results of cutting force can be checked graphically

- Identify areas with high cutting loads that can lead to tool breakage in advance

MACHINING SIMULATION

- Accurate machining simulation for NC programs

- Interference check function to prevent interference during machining, interference areas are displayed in red

- Time study function for accurate cycle time estimation

- Comparison function between CAD-designed 3D model and simulated cutting geometry

- Supports not only programs created with CAD / CAM, but also simulations using the MAPPS conversational programming function 3, 4

1 Only available in Optimization Edition

2 The values listed may not be obtained depending on the type of machining

3 SIEMENS conversational programming software, ShopMILL, and ShopTURN are not supported

4 Can also be used for NC programs created with your own CAD / CAMs

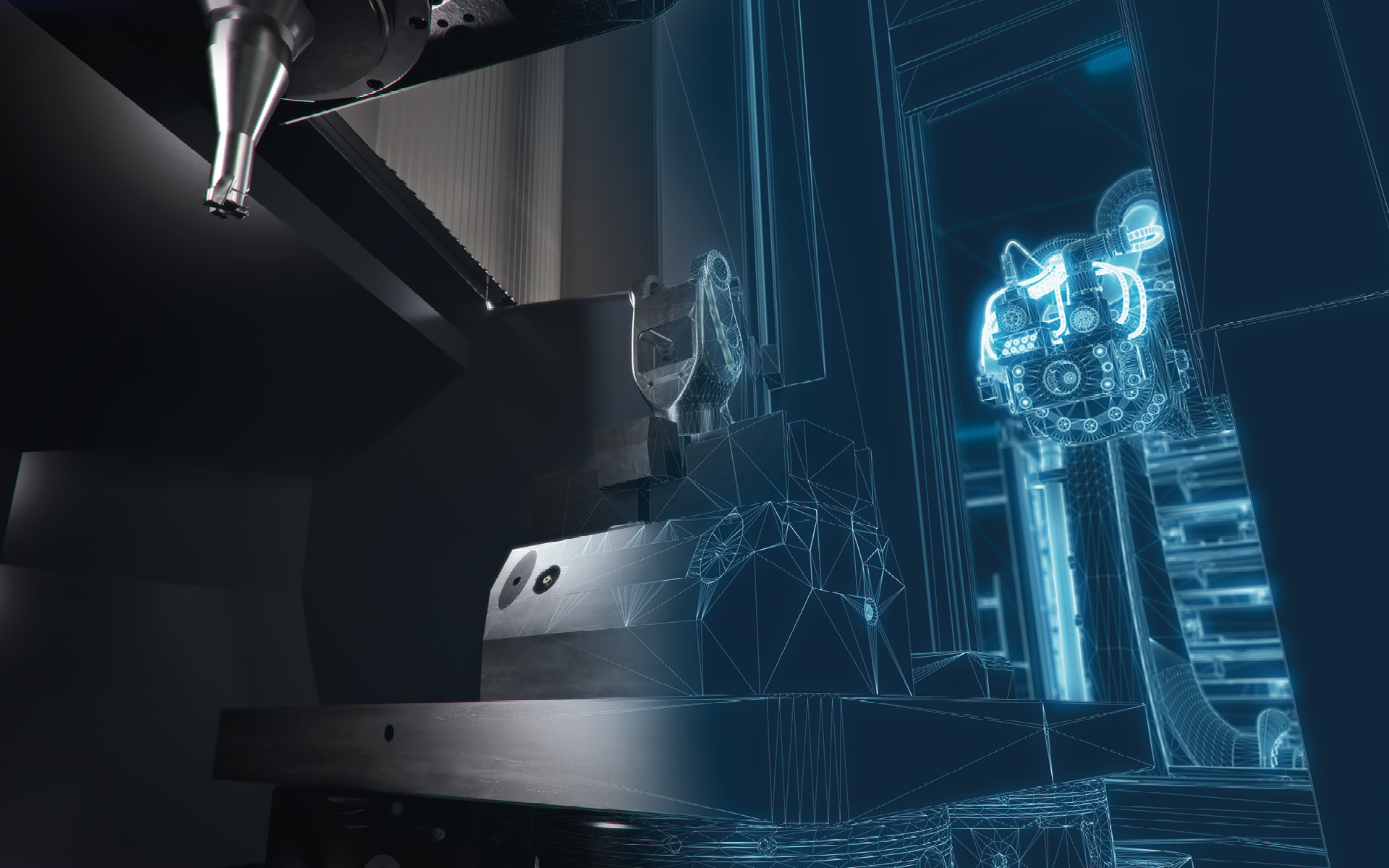

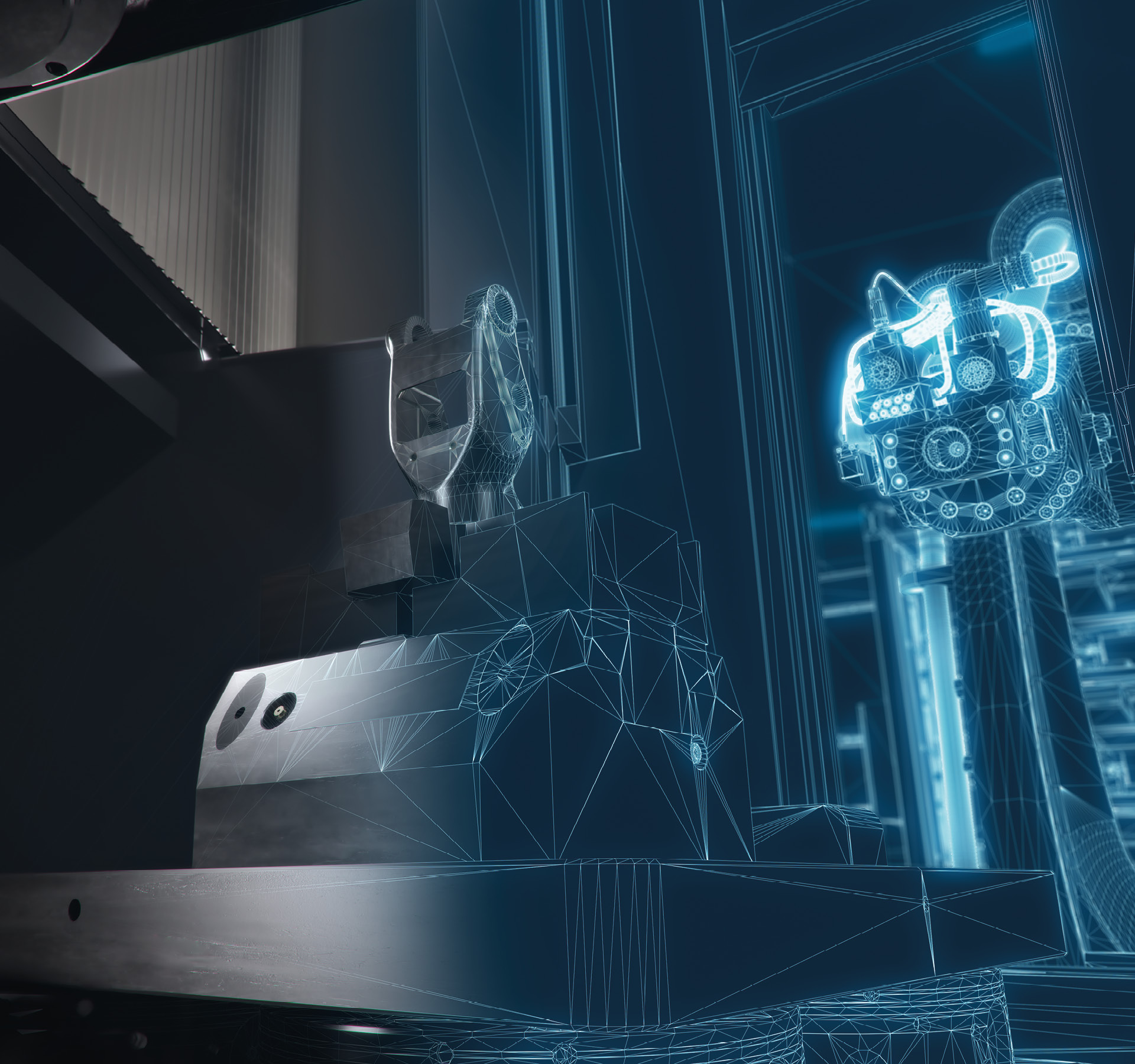

DIGITAL TWIN

- 40 % faster production ramp-up

Carry out employee training and non-productive activities digitally - Up to 80 % faster start of production

Less testing and development on the machine - 100 % collision-free run-in

Complete digital testing and optimization

DIGITAL TWIN Hightlights

- Increase of the productively used spindle hours

- Shifting non-production activities, such as run-in processes and programming to the virtual world

- Prevention of machine breakdowns due to collisions

- Reduction of component times

- Reduction of the cycle times thanks to process optimization and transparency of cost drivers

- Prevention of waste thanks to previous simulation and simplified error detection

- Qualification of the employees

- Reduced error rate thanks to early training and, if required, ongoing training

- Simplification of complicated work tasks through increasing the transparency

DMG MORI Test Cut

- Simulation instead of real machines

- Safe test machining and fast results

- No workpiece or tool costs

- Low effort for estimating cycle times

EXAMPLE – 5-axis process // free-form surface machining

- 8 hours in the real machining

- 10 min digitally

- No use of materials, tools, and operating materials

- No machine required

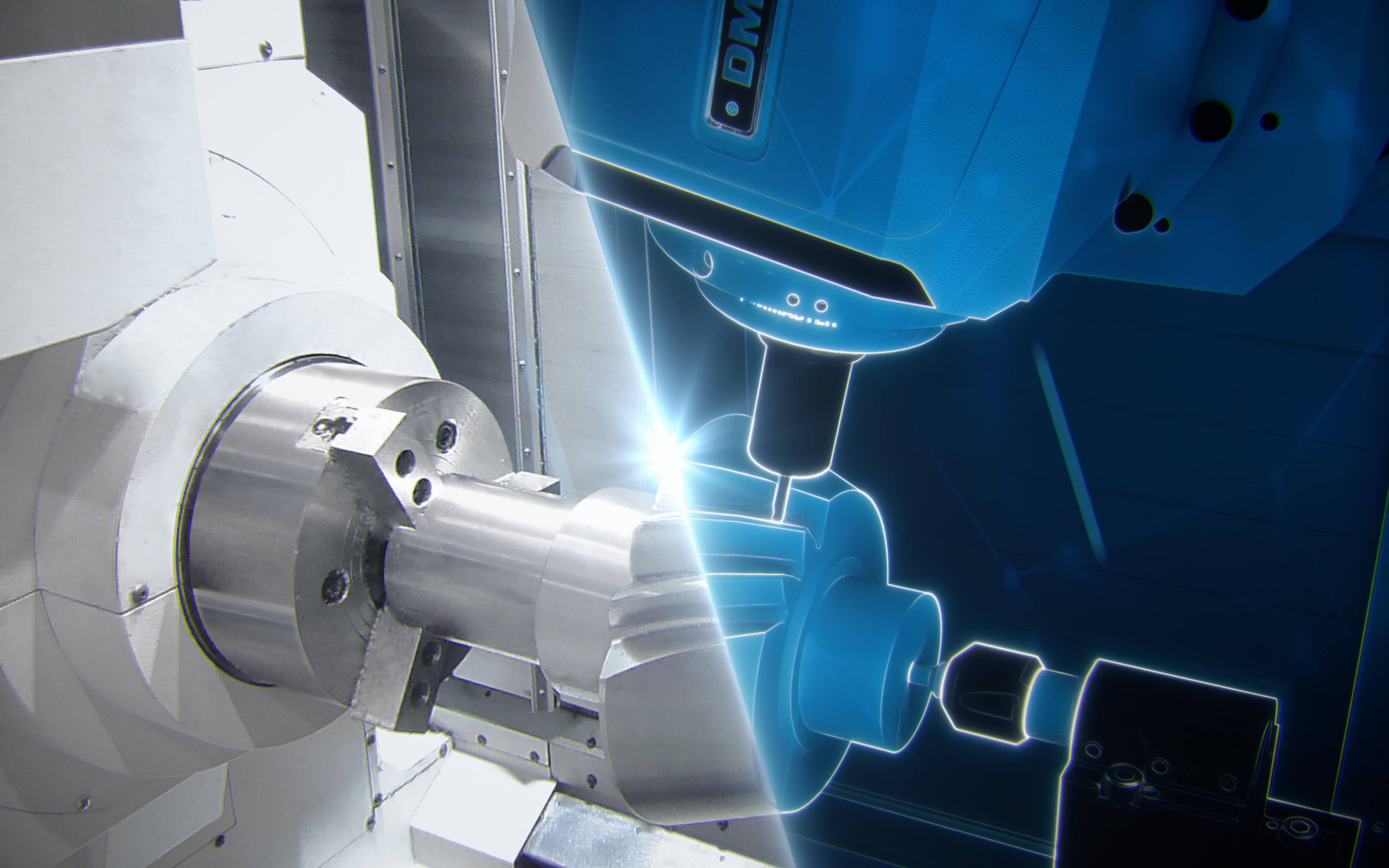

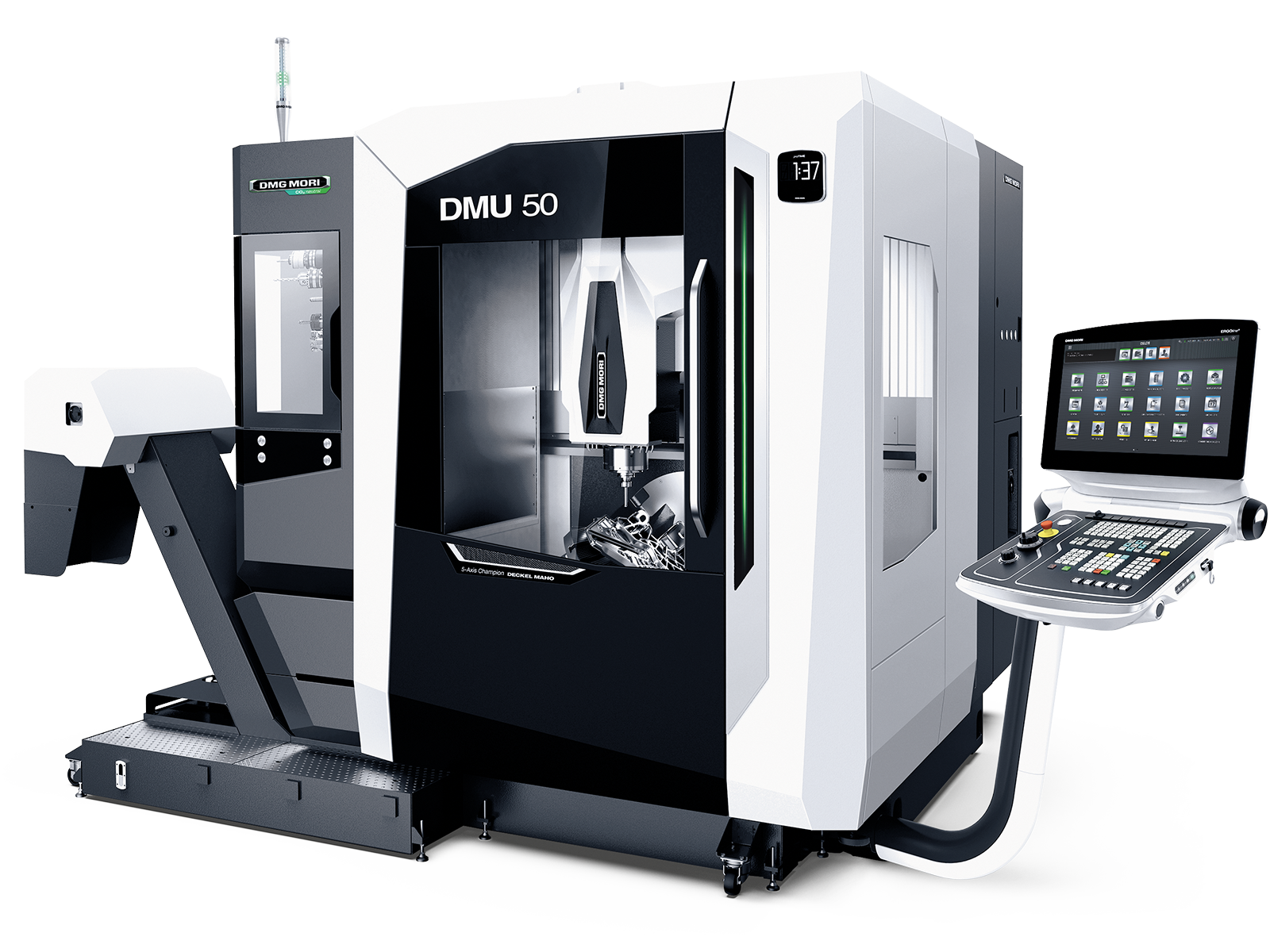

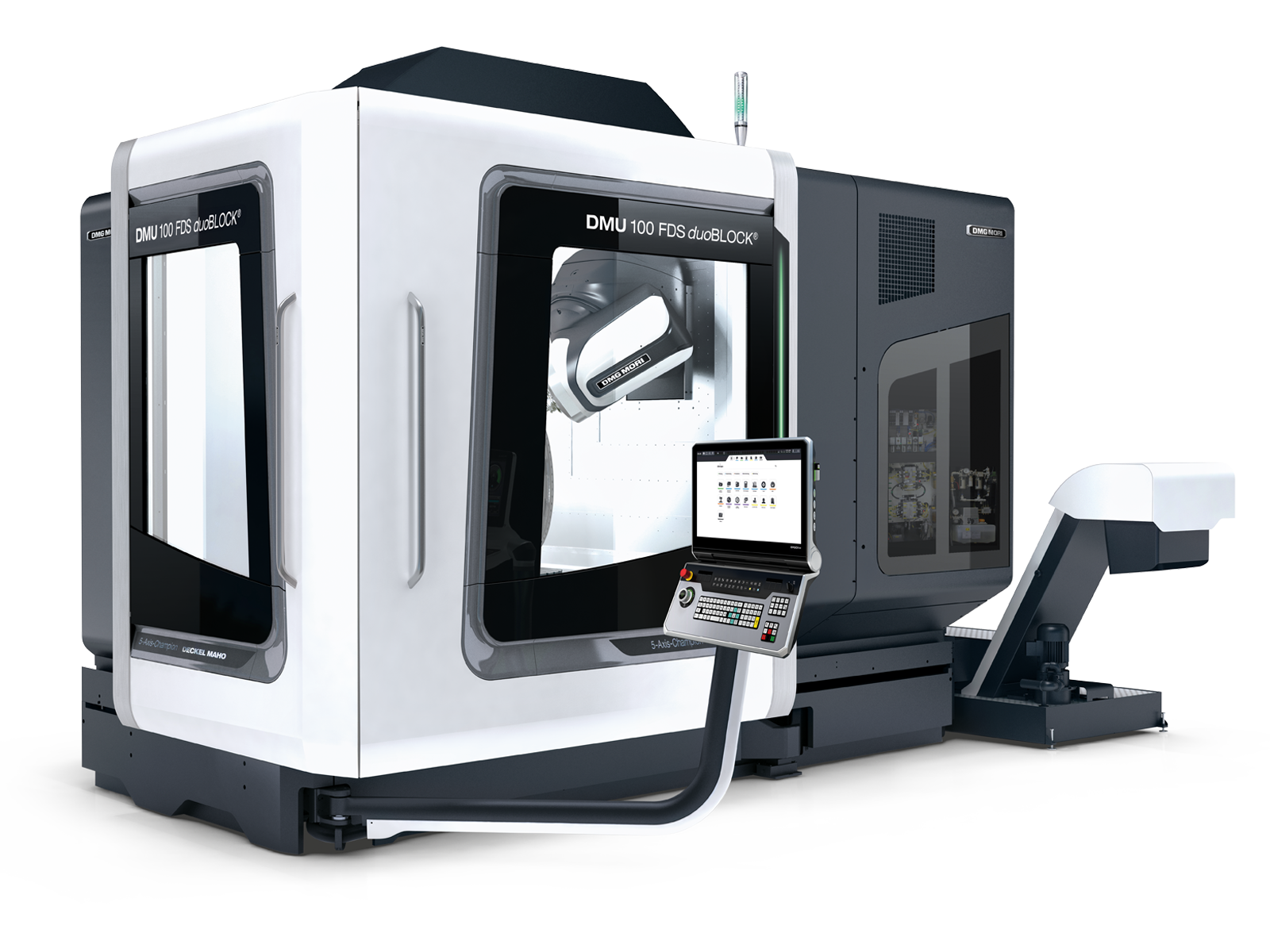

Process Integration

Higher utilization of a complete machining center, instead of partial utilization of several simple machines.

Automation

For additional low-man or manless night and / or weekend shifts.

Digital Transformation (DX)

From CAD-CAM solutions and post-processors to simulation using Digital Twin and DMG MORI technology cycles for up to 60 % shorter programming time

Green Transformation (GX)

Integrated processes increase your productivity, reduce your energy consumption and maximize your profit.

Or call us!

Or call us!