Additive

Manufacturing

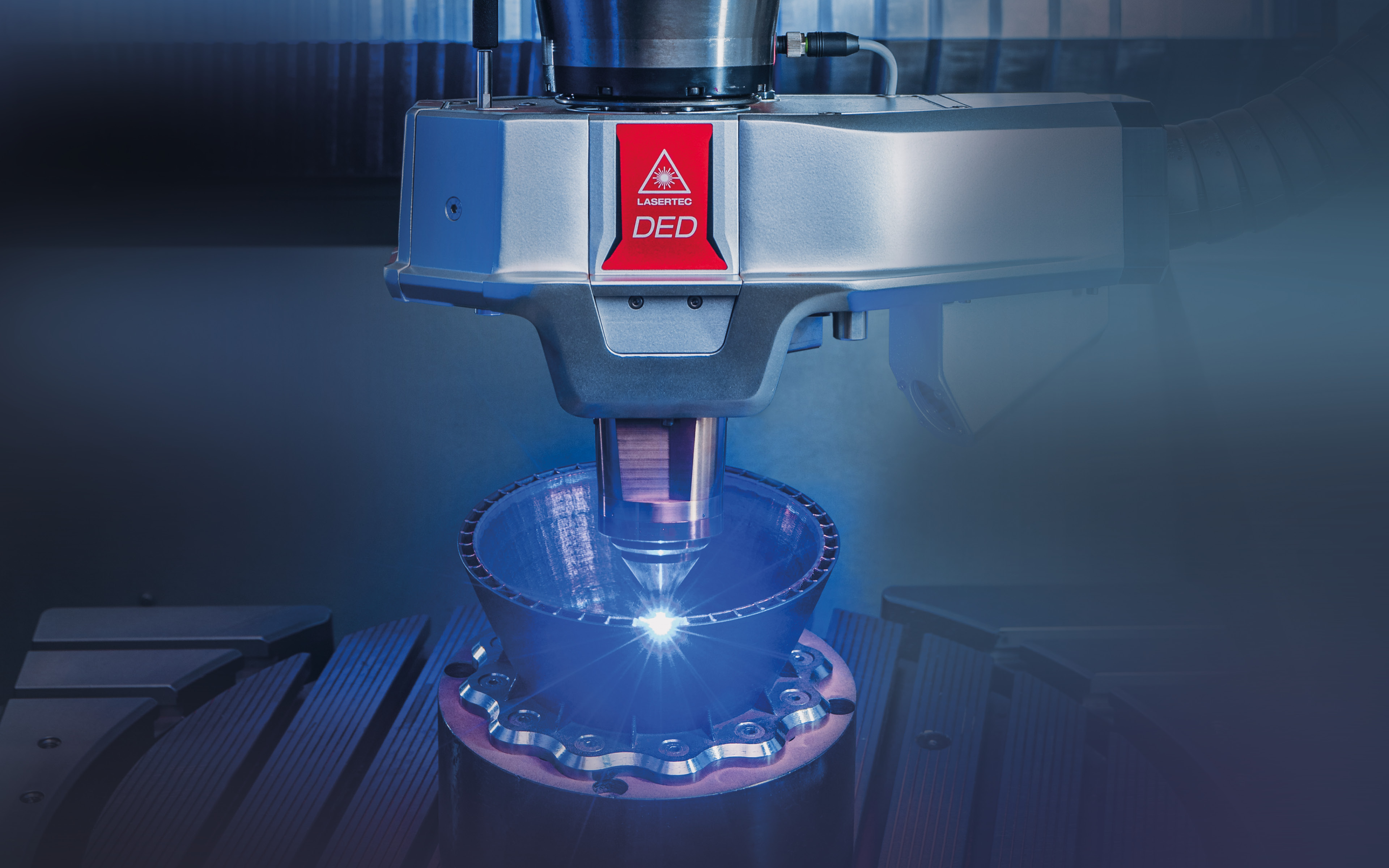

DED / DED hybrid

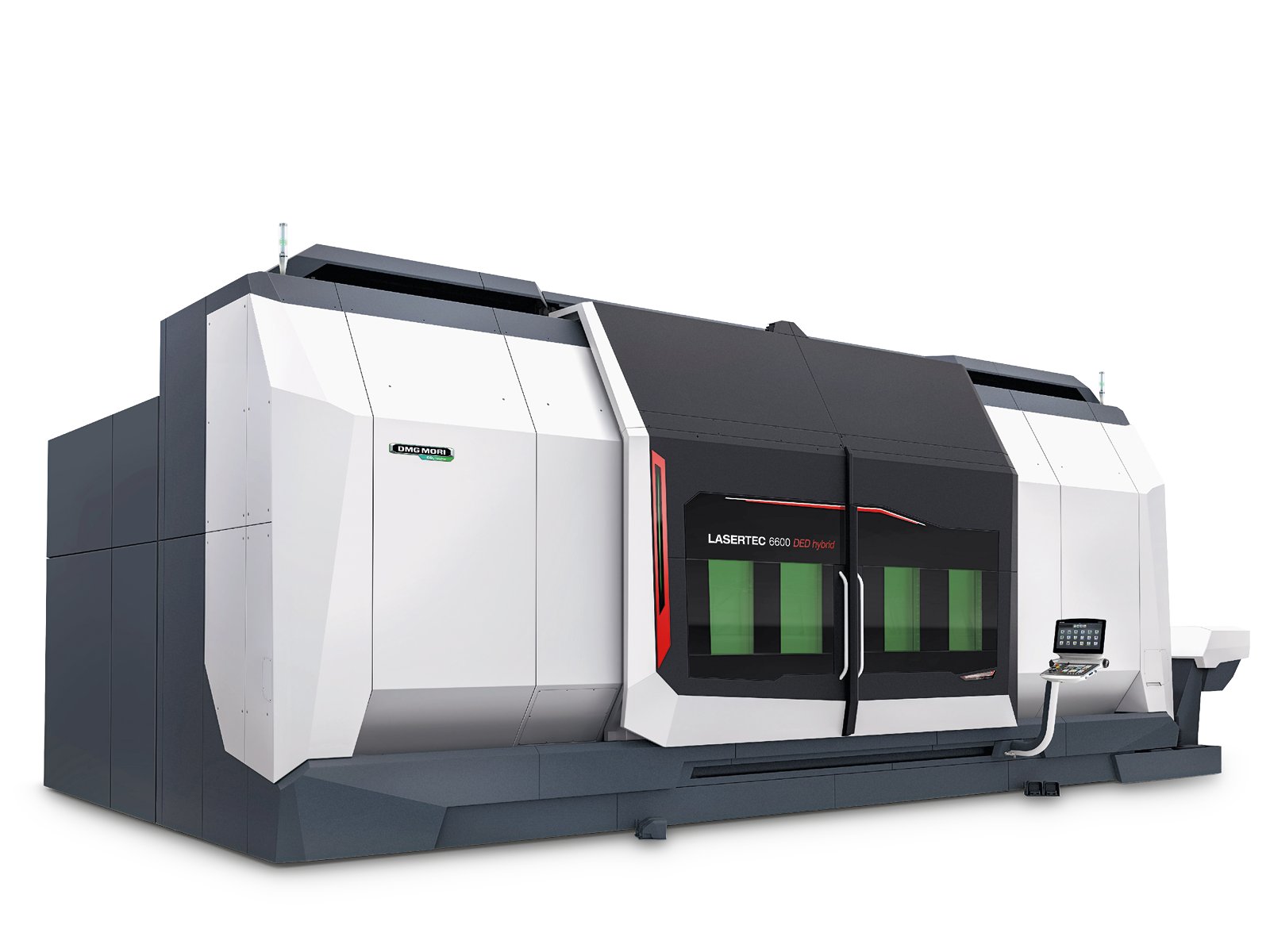

Highlights

- The laser deposition head is handled by a fully automatic shuttle without manual intervention

- Up to 1 kg build-up rate per hour (depending on material): 5-axis material deposition by coaxial nozzle for homogeneous powder distribution, independent of direction of laser deposition welding

- Fibre-guided diode laser with 3,000 W power and 600 µm fibre diameter as standard

- Optional with fibre guided laser with 2 kW and blue wavelength (450 nm), perfect for highly reflecting materials like copper

- AM Assistant for excellent process reliability and comprehensive traceability, as well as powder feed rate sensor and automatic powder calibration

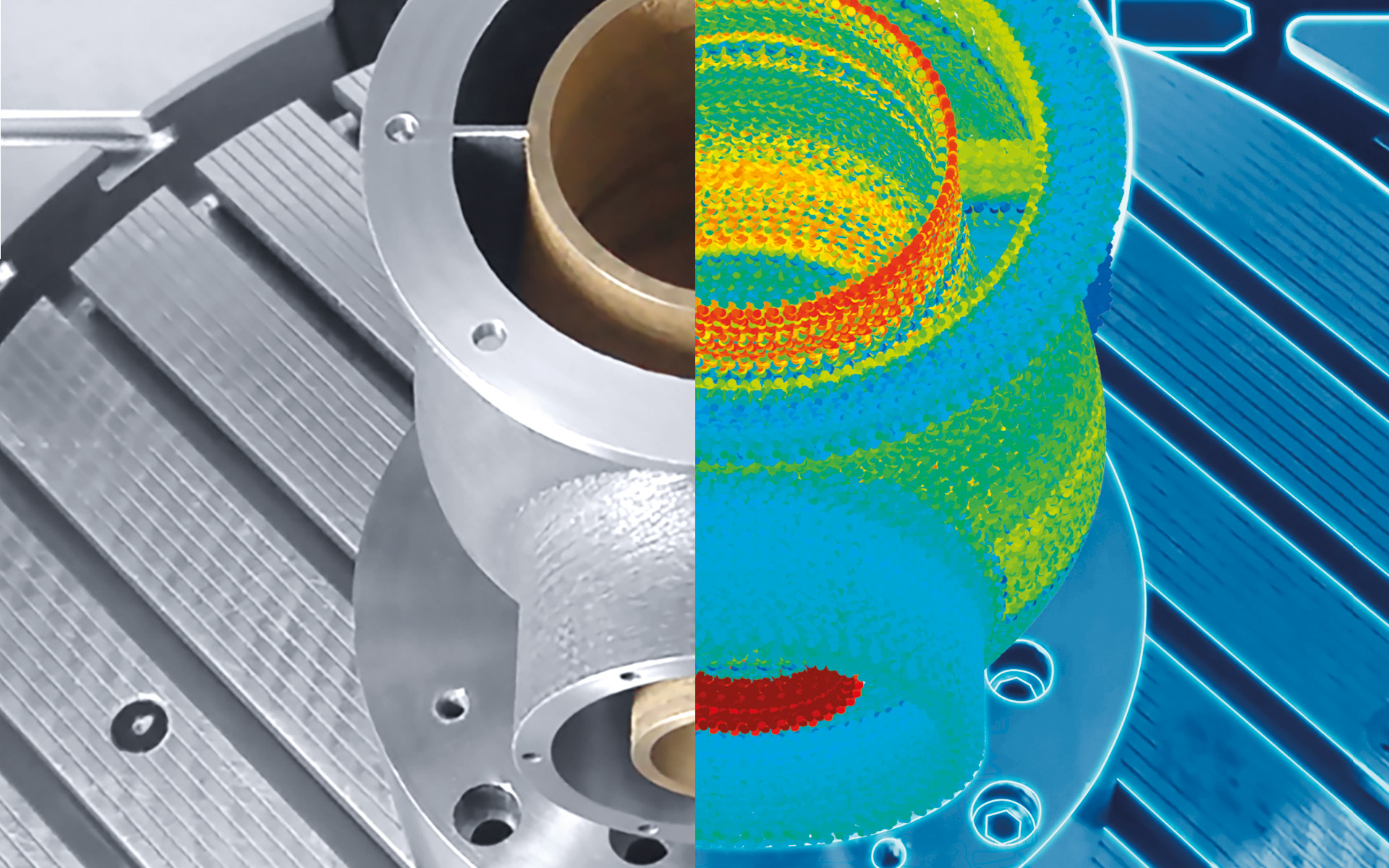

- Integrated thermal imaging camera for observation of the whole working area, adaptive process control and constant monitoring of the working distance

Workpieces

2-channel heat exchanger

- CuAl10 / 316L

- Energy

- ø 200 × 250 mm

Die cast core

- Ferro 55 + CuAl10

- Die & Mold

- 120 × 82 × 123 mm

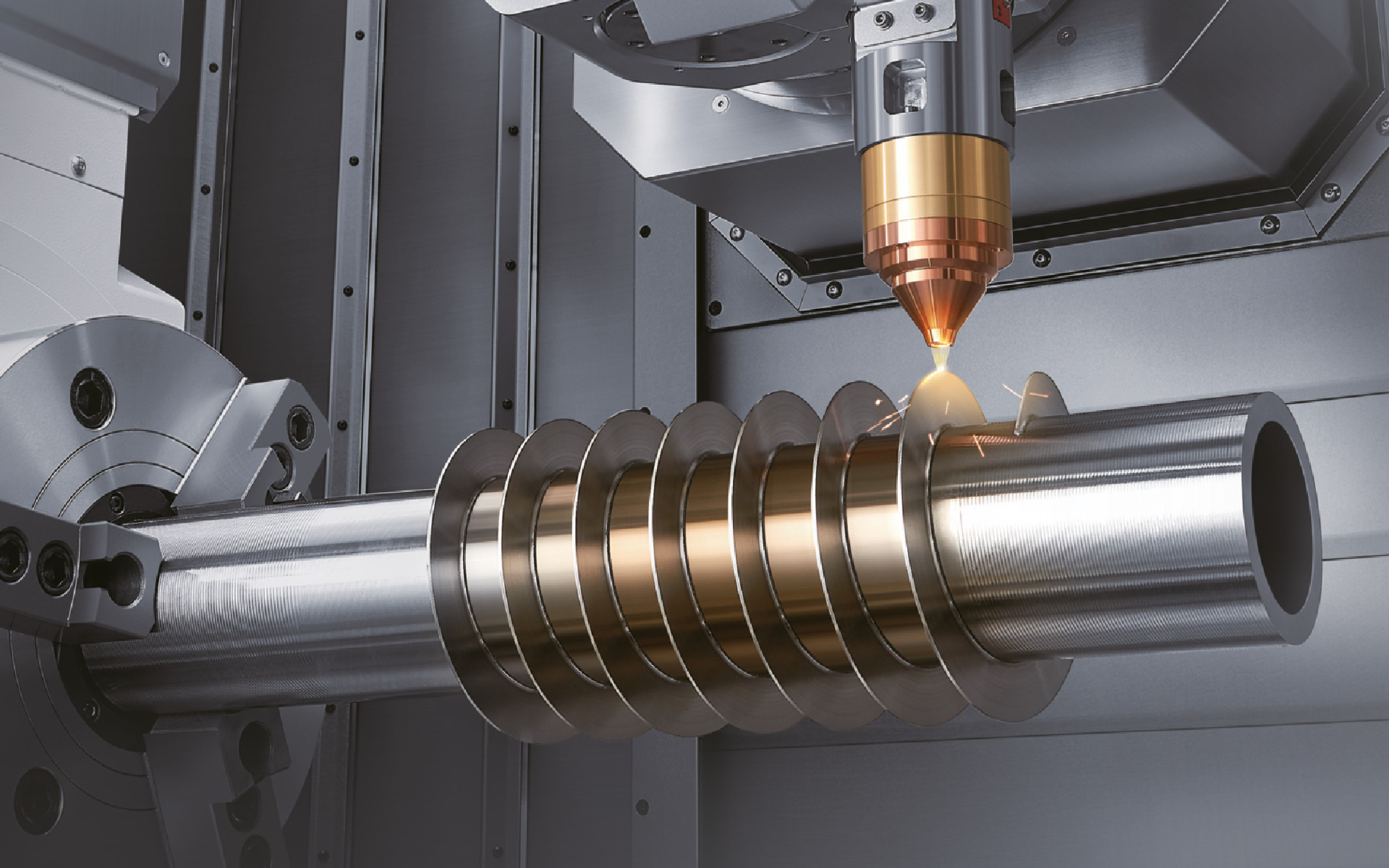

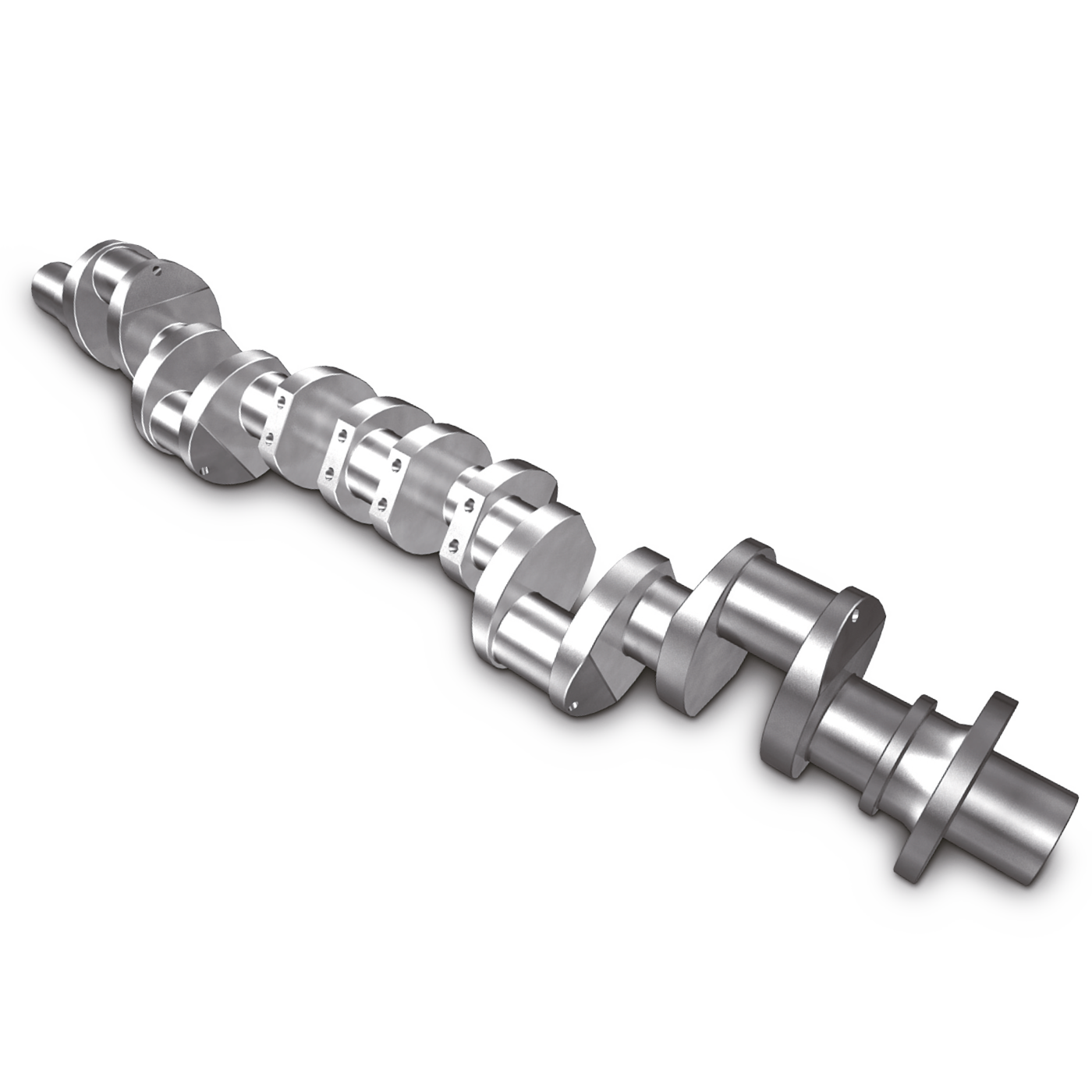

Crank shaft (coating)

- Cobalt alloy

- Marine

- ø 600 × 3,200 mm

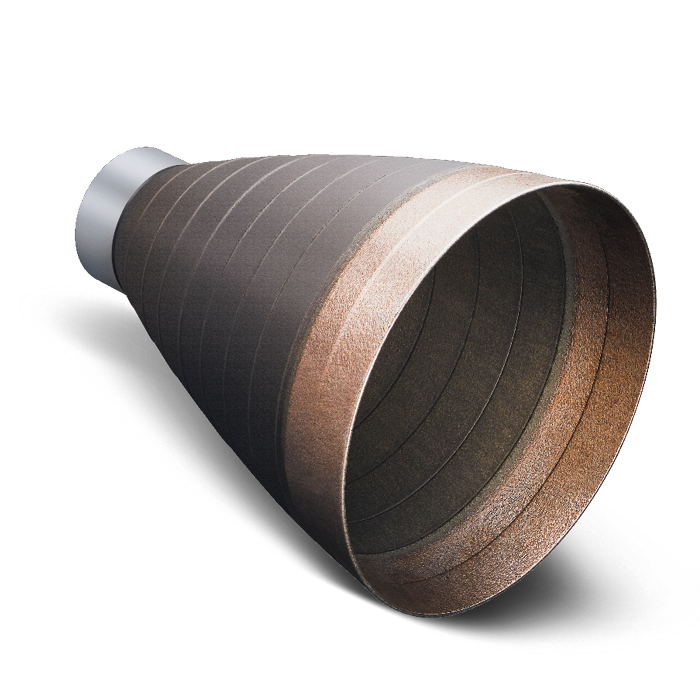

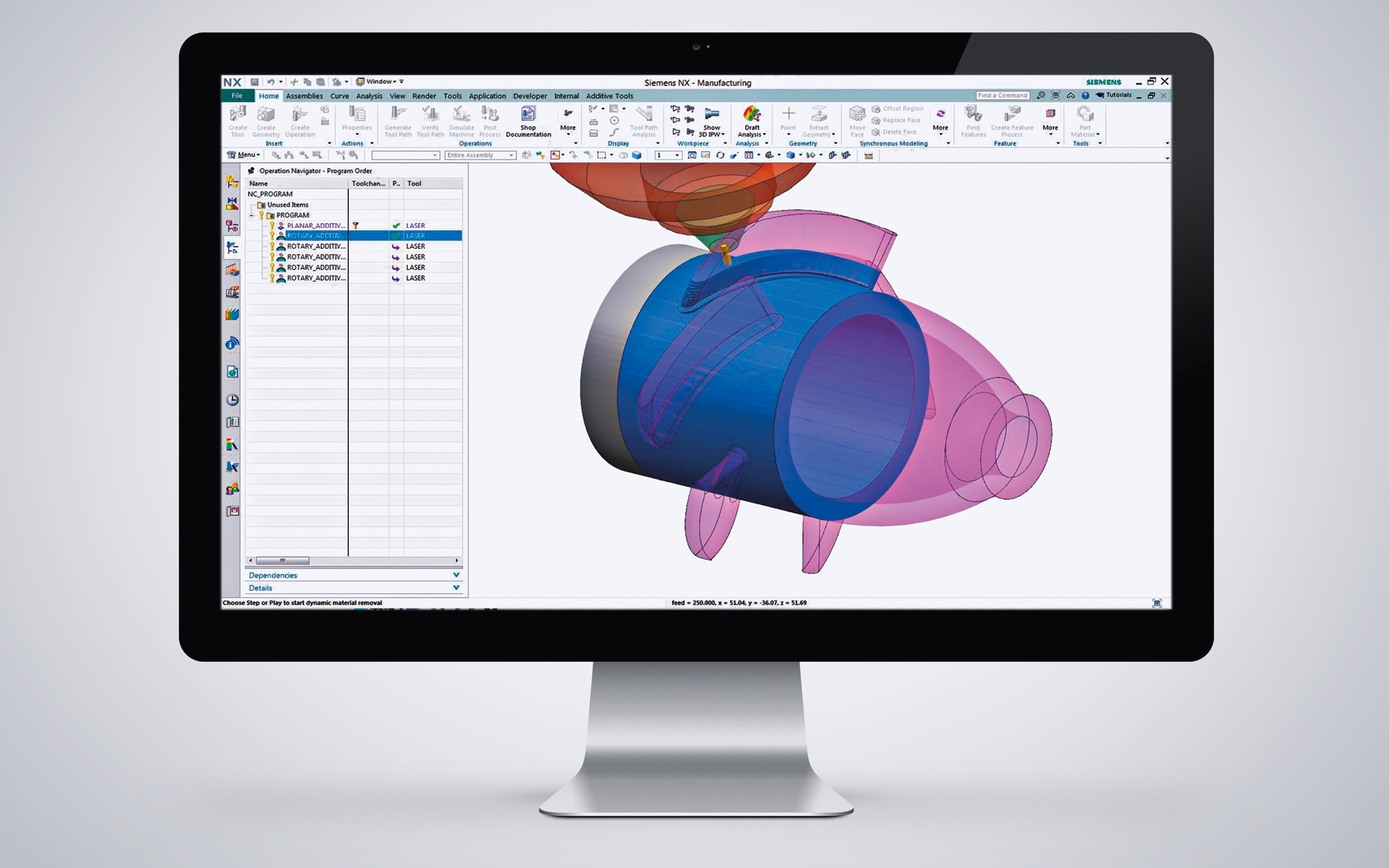

Rocket nozzle

- SUS316L

- Aerospace

- ø 450 × 470 mm

Or call us!

Or call us!