Integrated processes

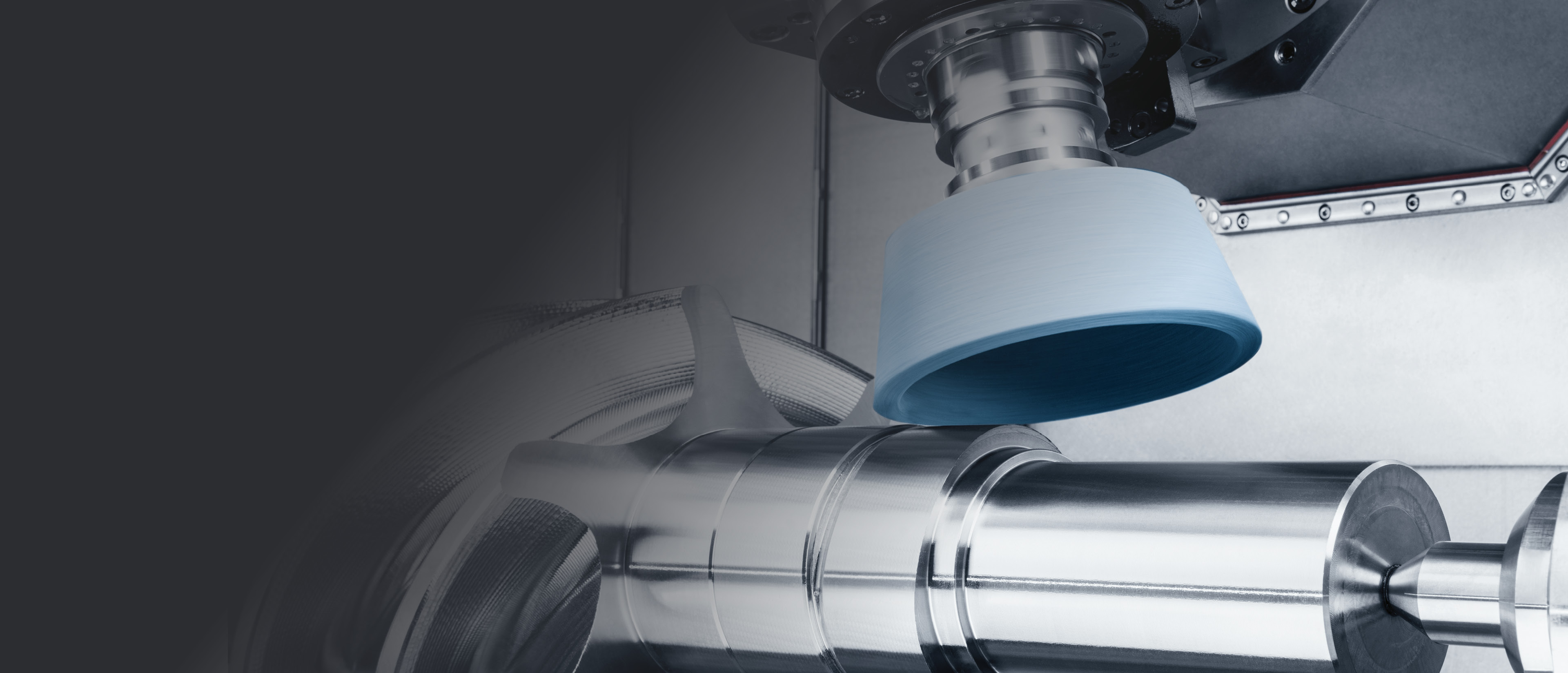

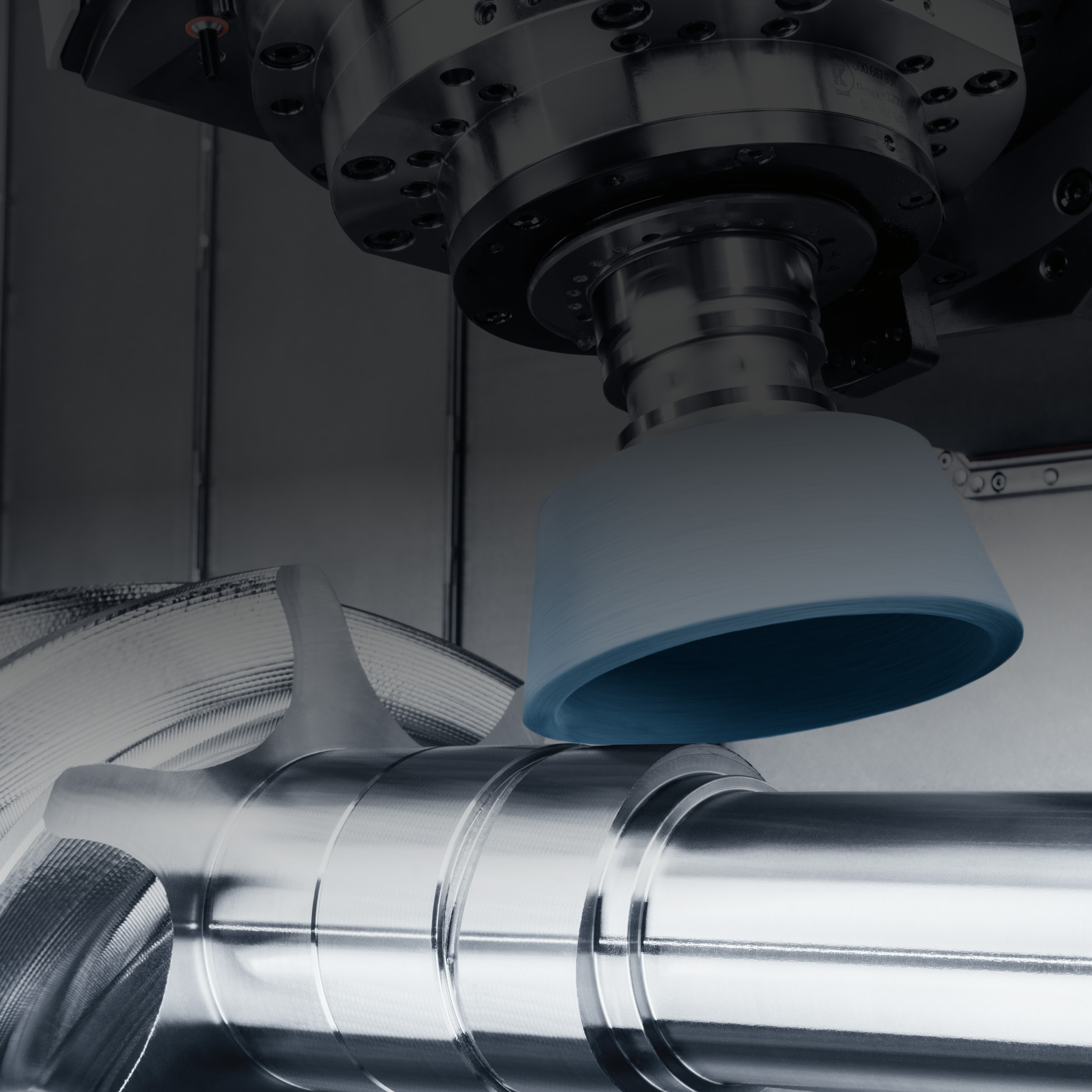

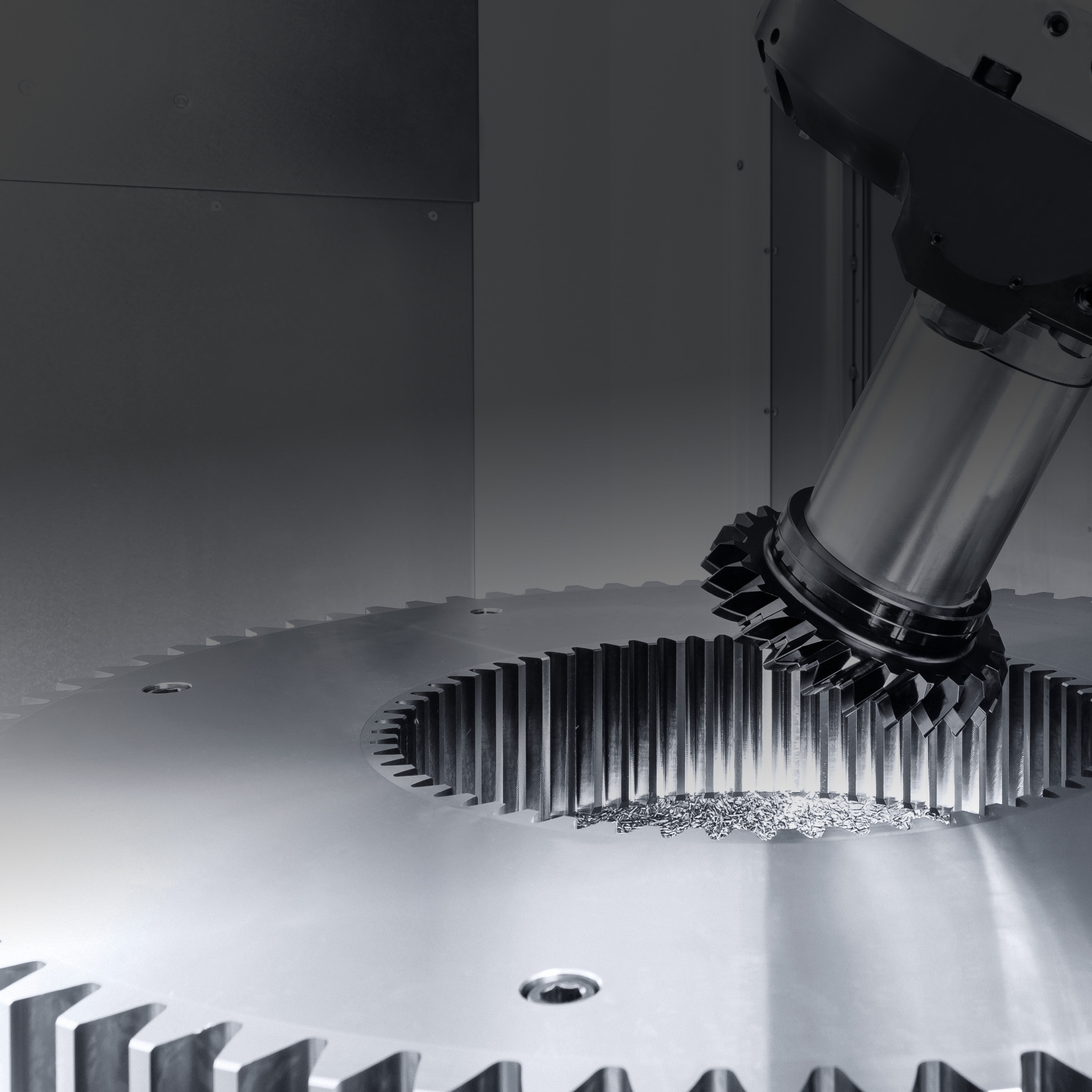

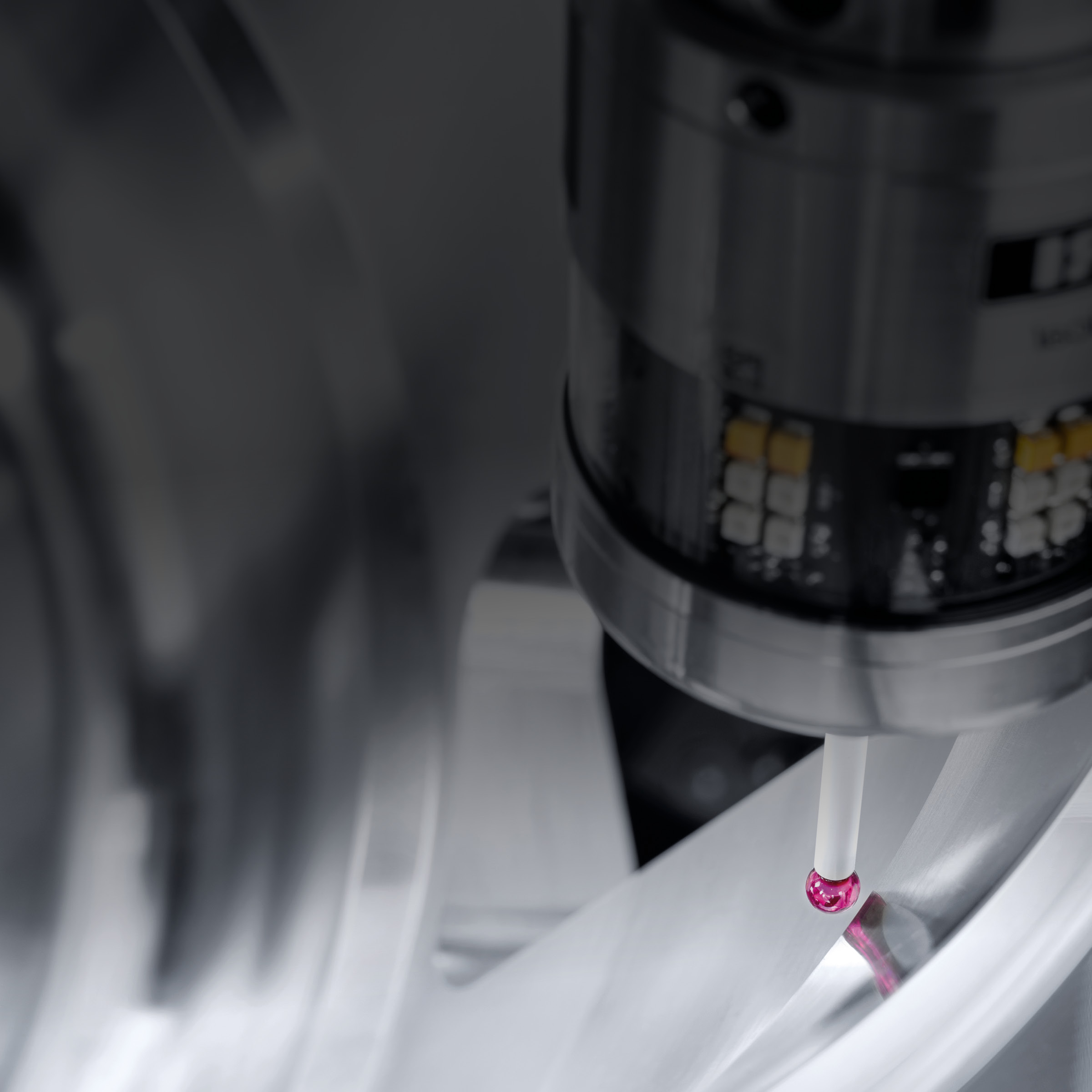

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

Highlights

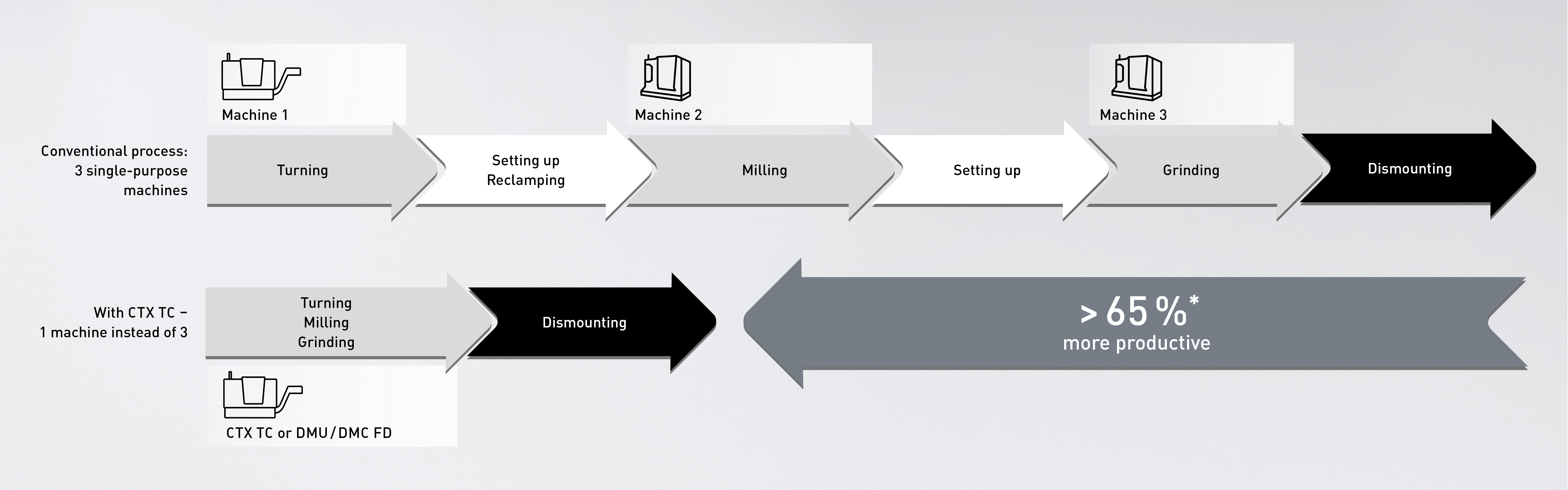

- Turning, milling and grinding in one set-up

- Process reliability and economy due to elimination of special machines and reduced grinding allowance

- Grinding cycles for internal, external and surface grinding, polygonal and oval grinding as well as dressing cycles

- Simple dressing and optimised commissioning with the aid of structure-borne sound sensors

- Excellent surface quality through integration of grinding technology

- Intuitive and 60% faster programming through conversational programming – DMG MORI technology cycles

Workpieces

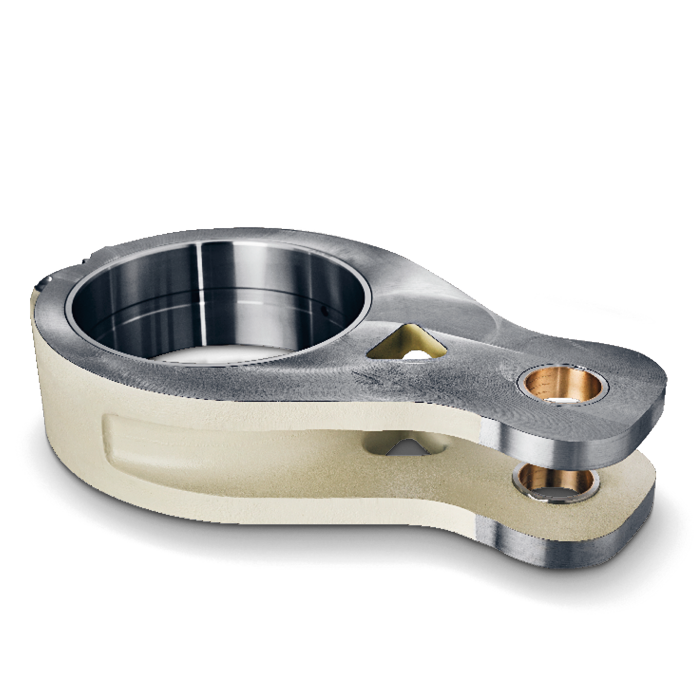

Connecting rod

- EN-GJS-600-3, 100Cr6

- Engineering

- 704 × 368 × 128 mm

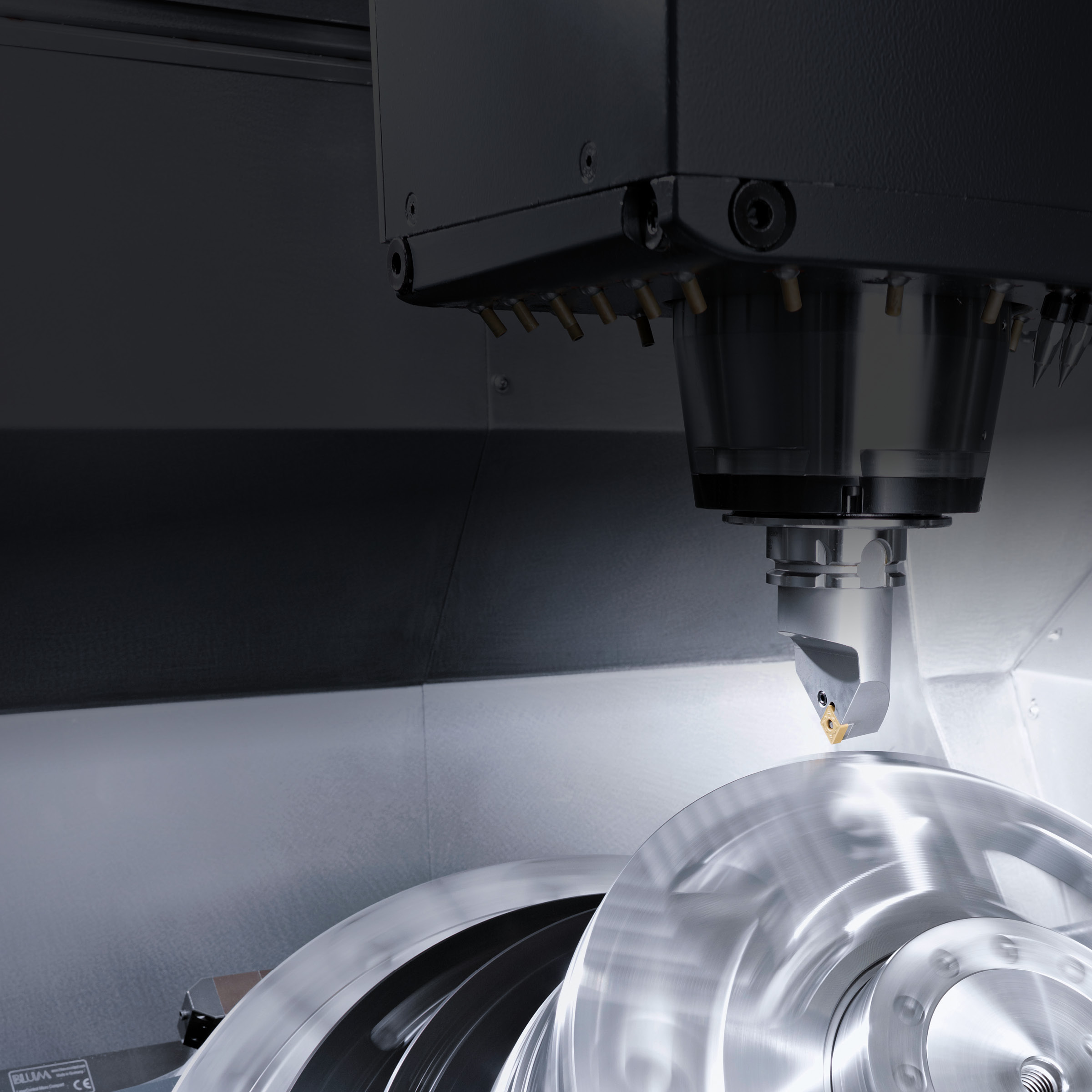

Disk

- Inconell 718

- Aerospace

- ø 400 × 70

Worm shaft

- 16MnCr5

- Engineering

- ø 175 × 380 mm

Screw

- 16MnCr5

- Engineering

- ø 250 × 1,000 mm

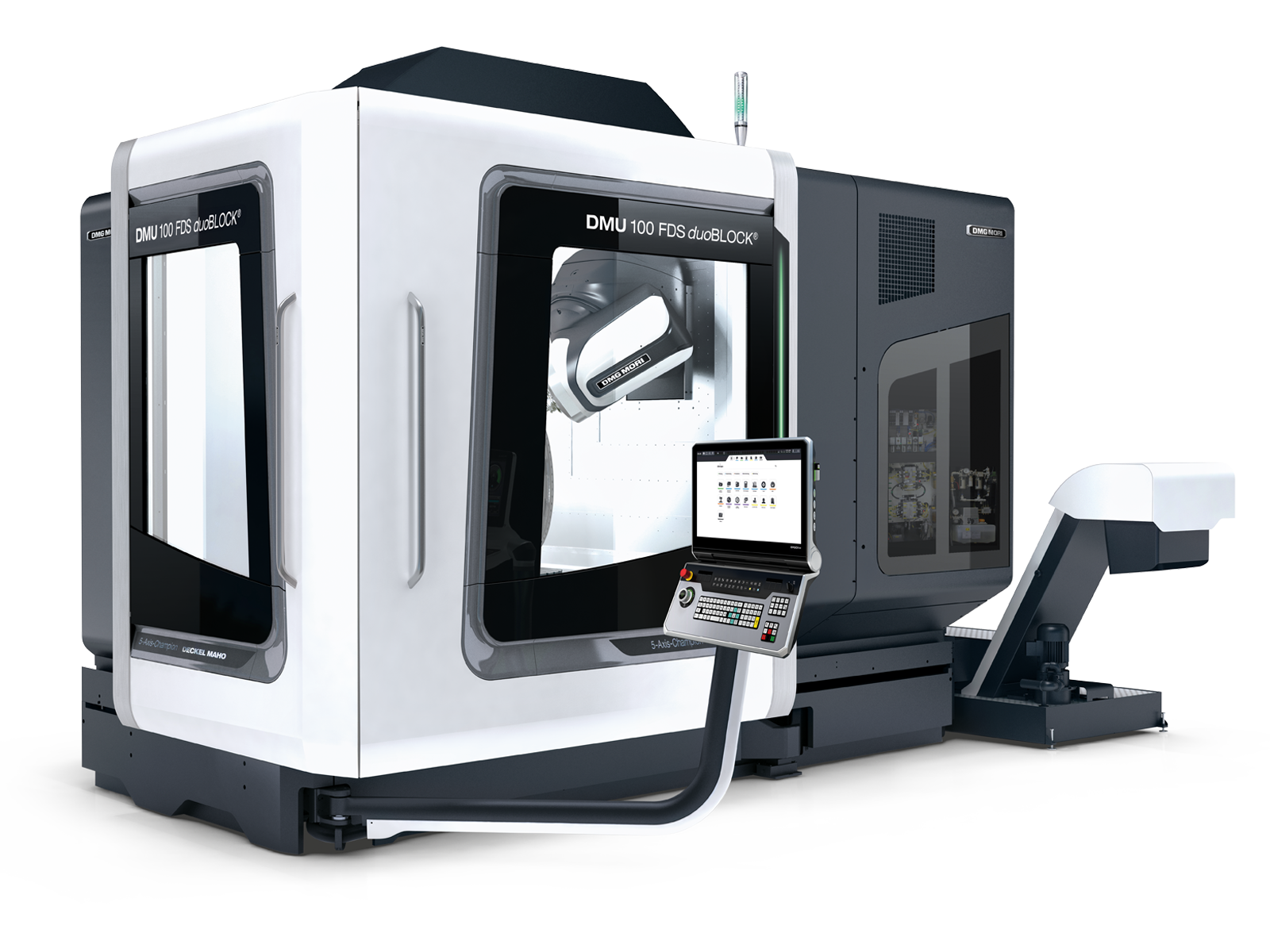

Grinding on Turn & Mill and Mill & Turn (FD) Machines

CTX TC

Grinding technology on Turn & Mill machines

- Turning, milling and grinding in one set-up

- Grinding cycles for internal, external and surface grinding, dressing cycles, as well as structure-borne sound sensor technology for start-up and dressing

- Fully integrated measuring gauge for relative and absolute LIVE measurement during grinding, with measurement repeatability up to 0.8 μm – while machining is in progress

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality IT5 for ø > 30 mm

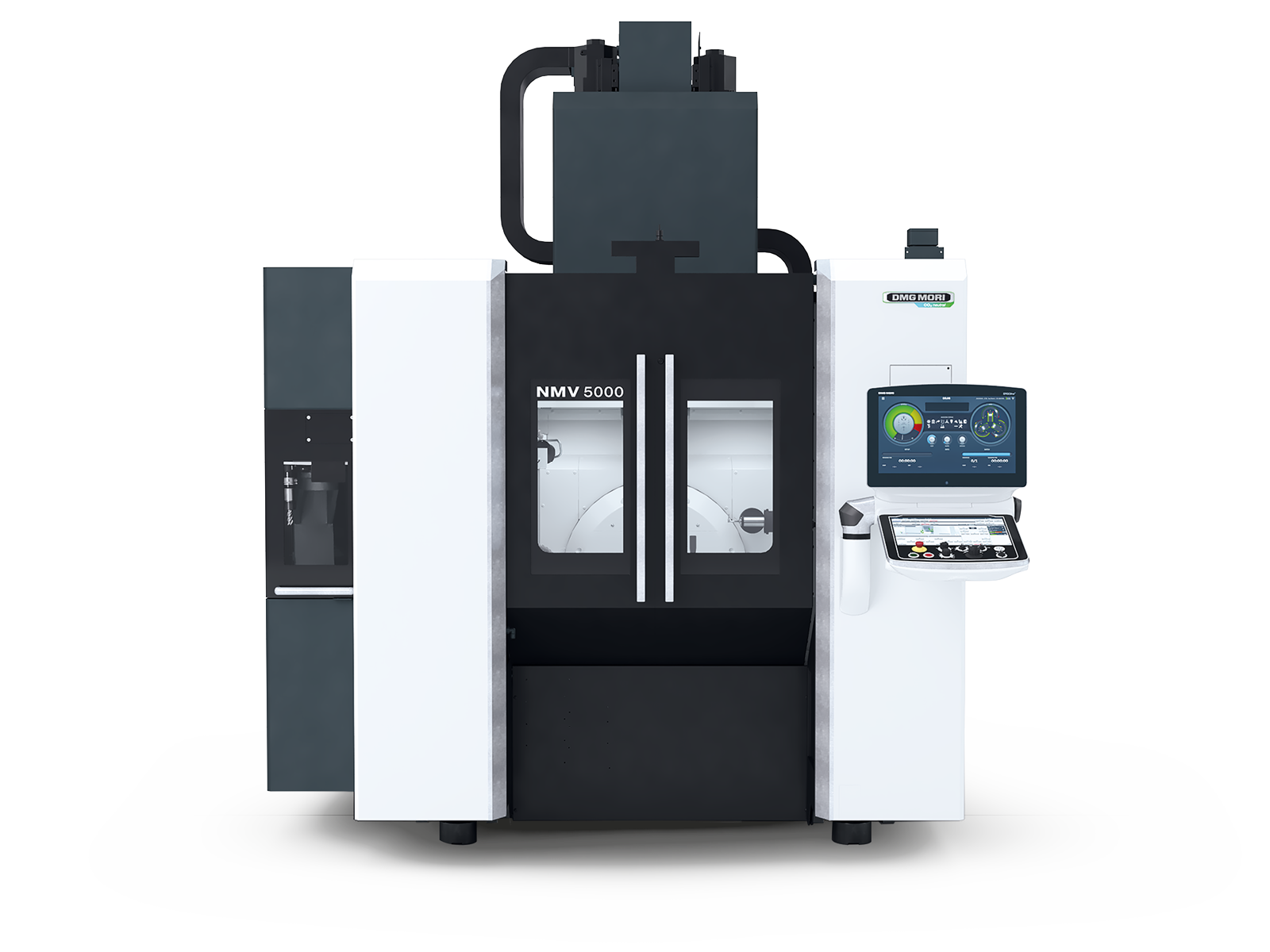

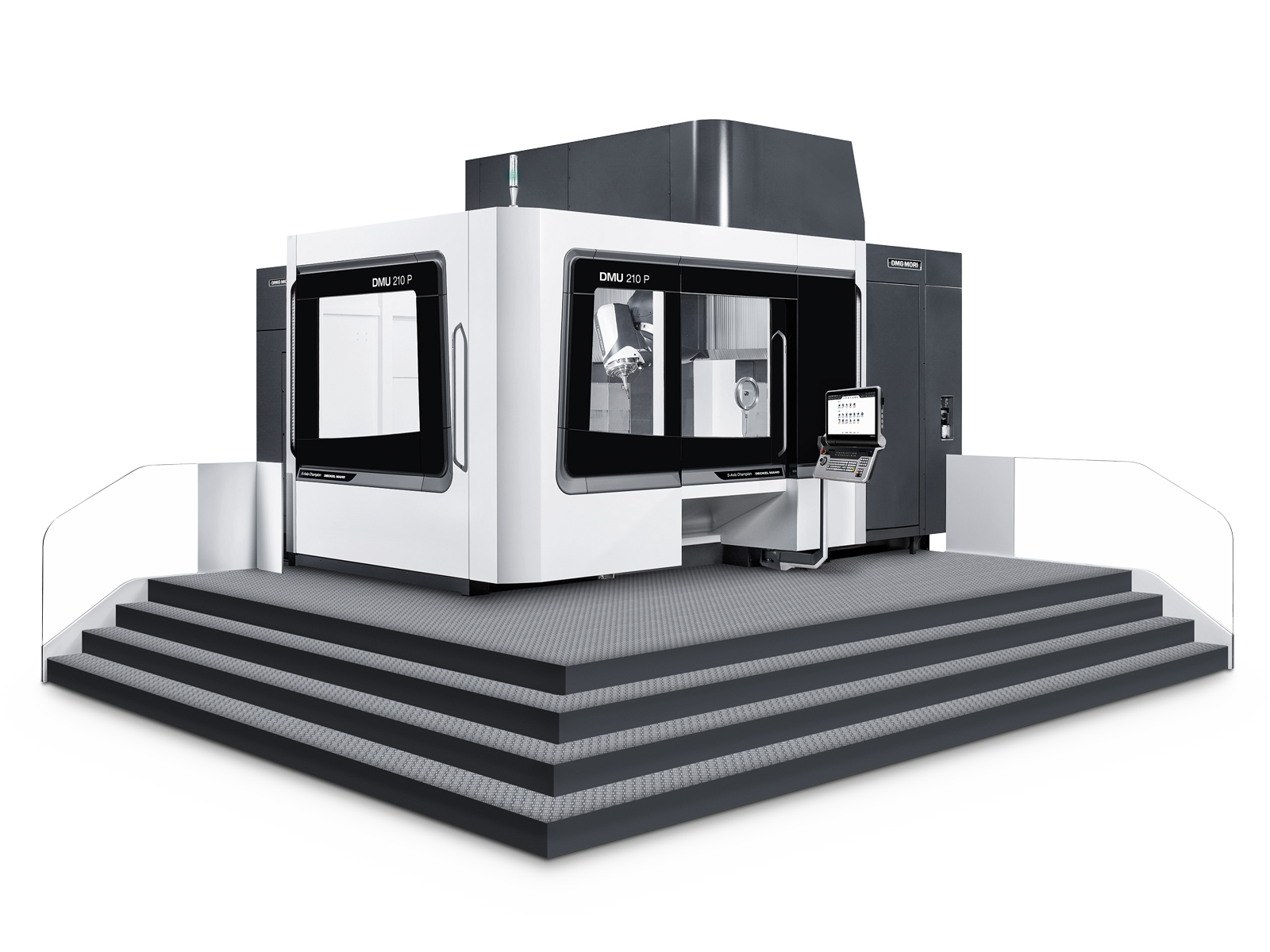

DMU / DMC FD

Grinding technology on milling (turning) machines.

- Grinding cycles for internal, external and surface grinding, as well as surface grinding cycle for grinding of long components or paths

- Dressing cycles, as well as structure-borne noise sensors for start-up and dressing

- AKZ nozzle unit is optionally available for best possible flushing of the grinding gap

- Surface accuracy < 0.4 μm

- Roundness < 5 μm

- Quality 5 for ø < 120 mm // Quality 4 for ø > 120 mm

Mill & Turn (FD)

Turning on 5-axis milling machines

Turn & Mill

6-sided complete machining by turning and milling

Grinding

Grinding for surface finishes with Ra up to 0.1 µm

Gear Cutting

External & internal gear cutting up to ø 3,200 mm and gear quality > 5

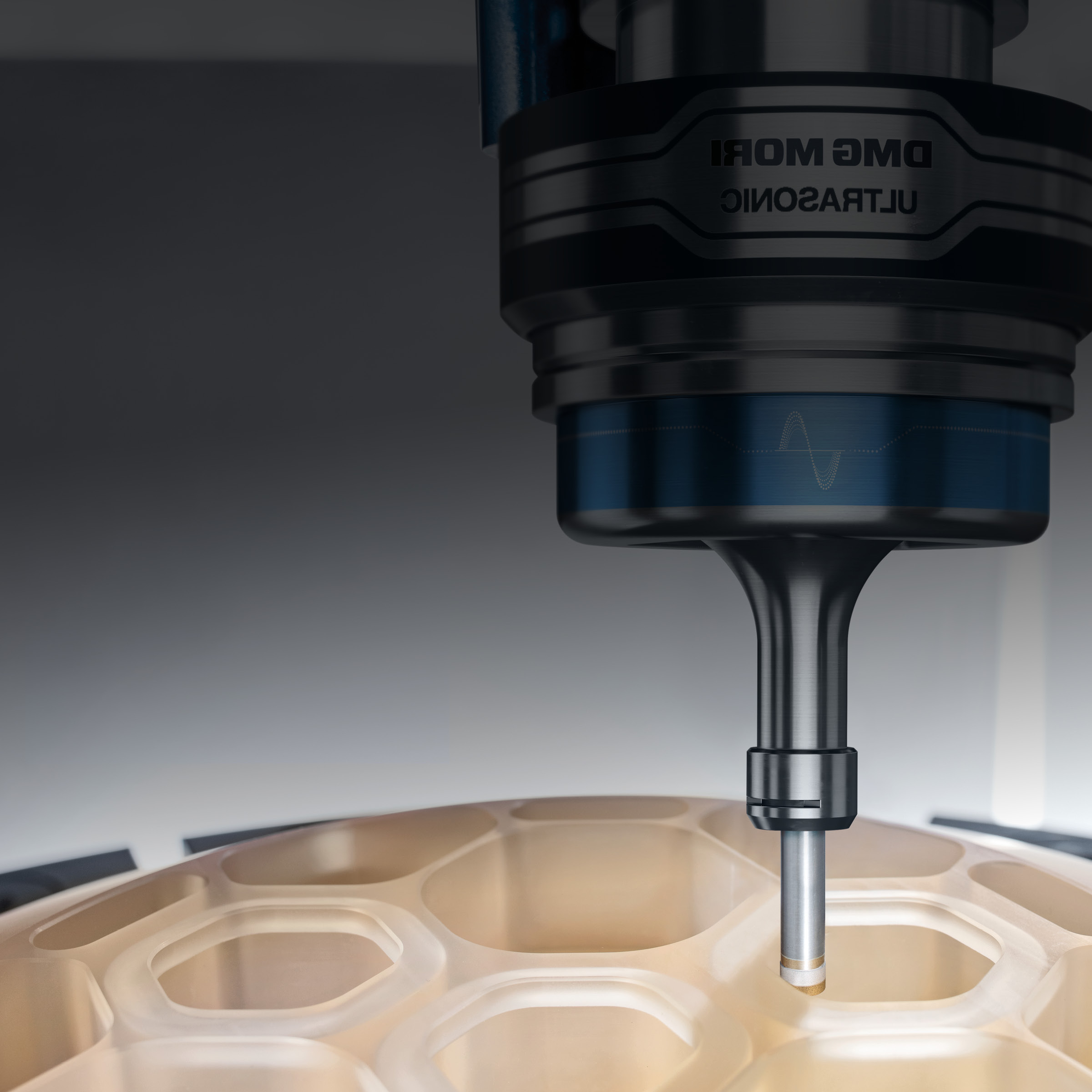

ULTRASONIC

Reduced process forces for very high productivity

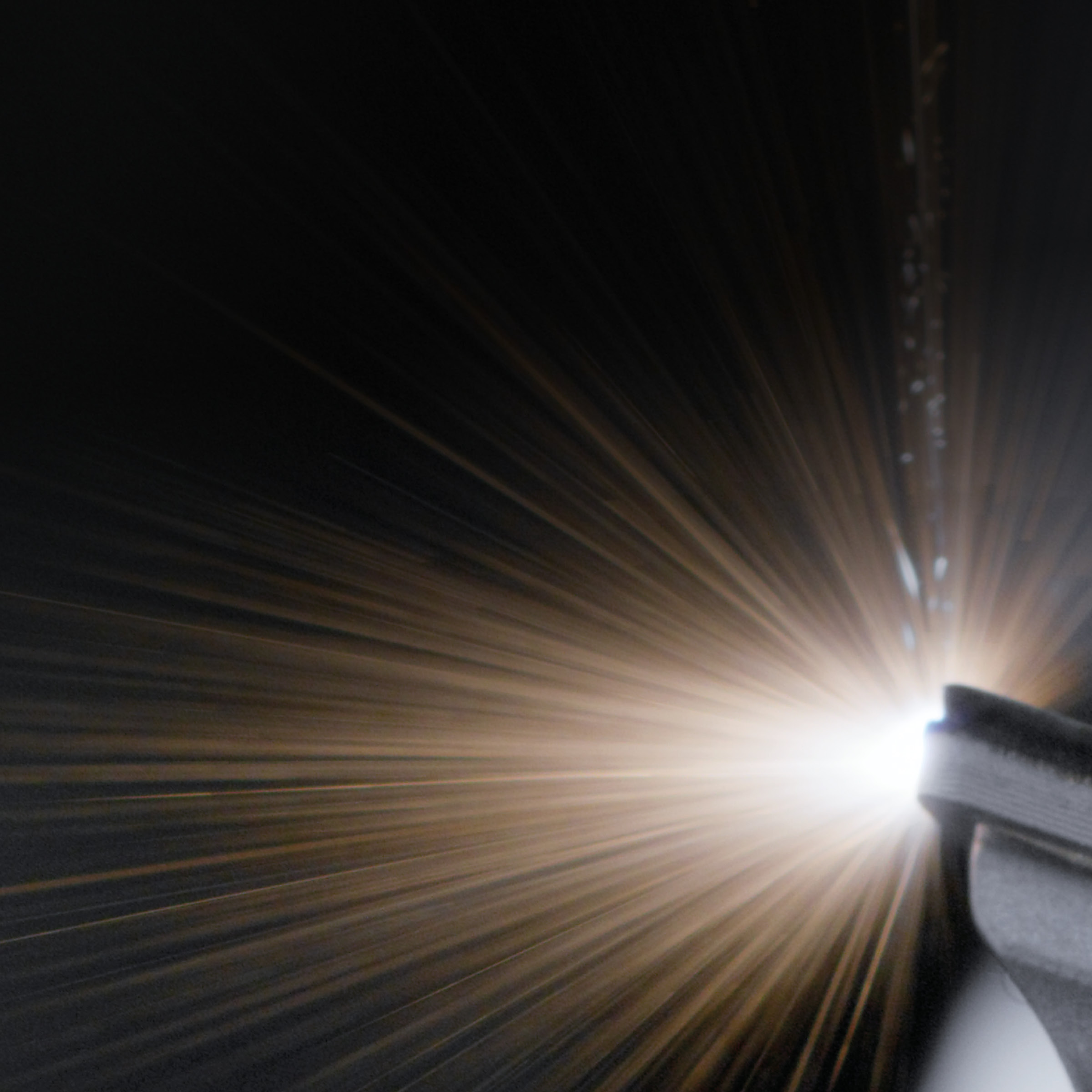

LASERTEC

Contact-free 5-axis laser machining

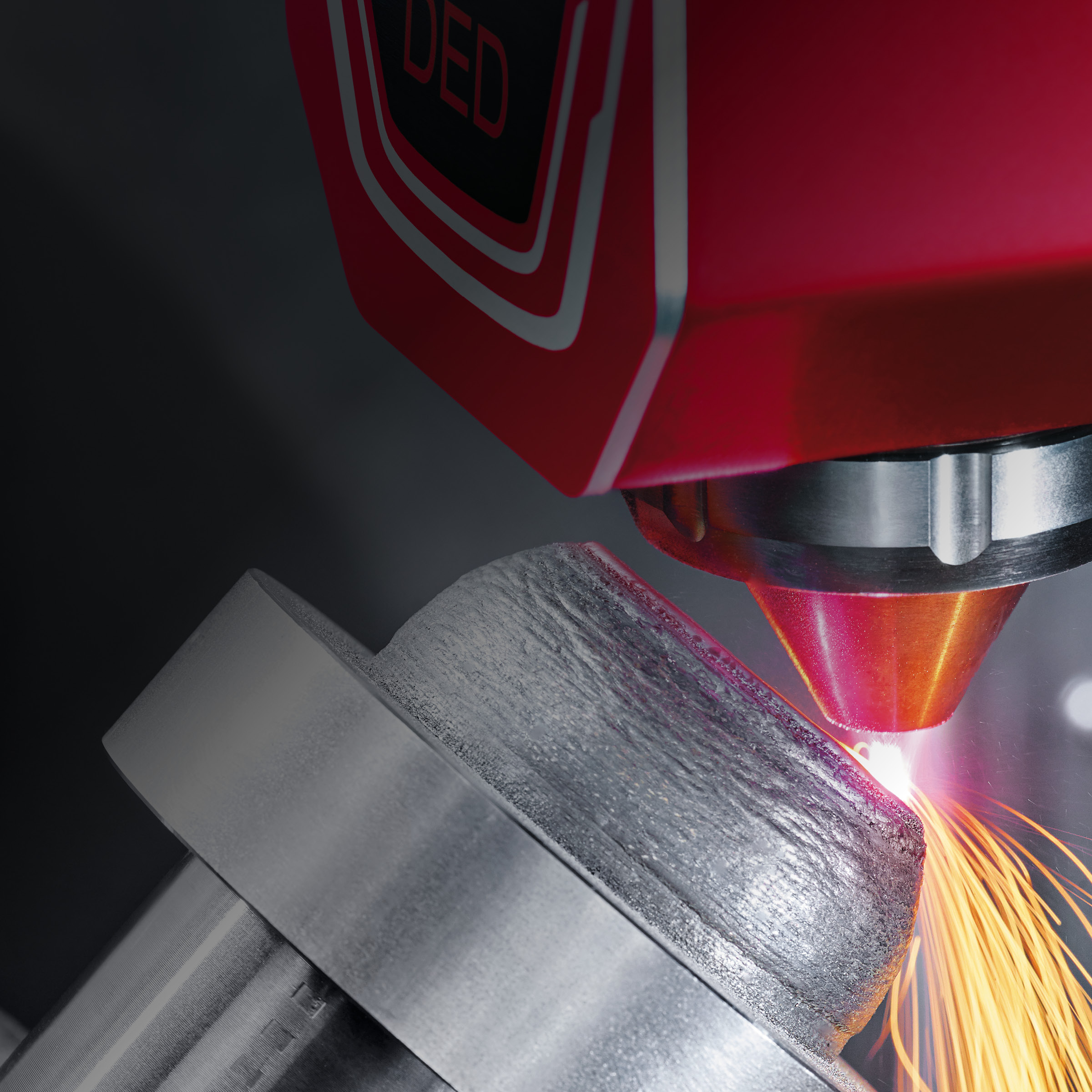

Additive Manufacturing DED hybrid

Milling, Turning and Additive Manufacturing on

In-Process Measuring

Higher process stability and reliability due to process monitoring & control

Or call us!

Or call us!